Gas barrier laminated film and laminated material using it

A gas barrier and film technology, applied in coatings, rigid containers, layered products, etc., can solve the problems of mechanical strength deterioration such as adhesive strength, gas barrier property reduction, and content quality deterioration, etc., to achieve excellent gas barrier properties , Excellent impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

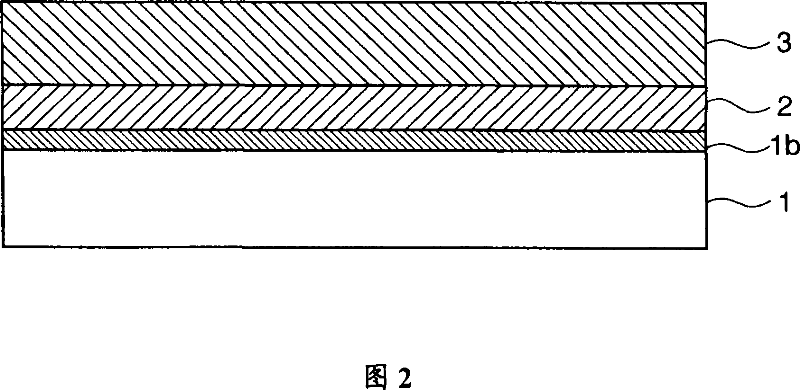

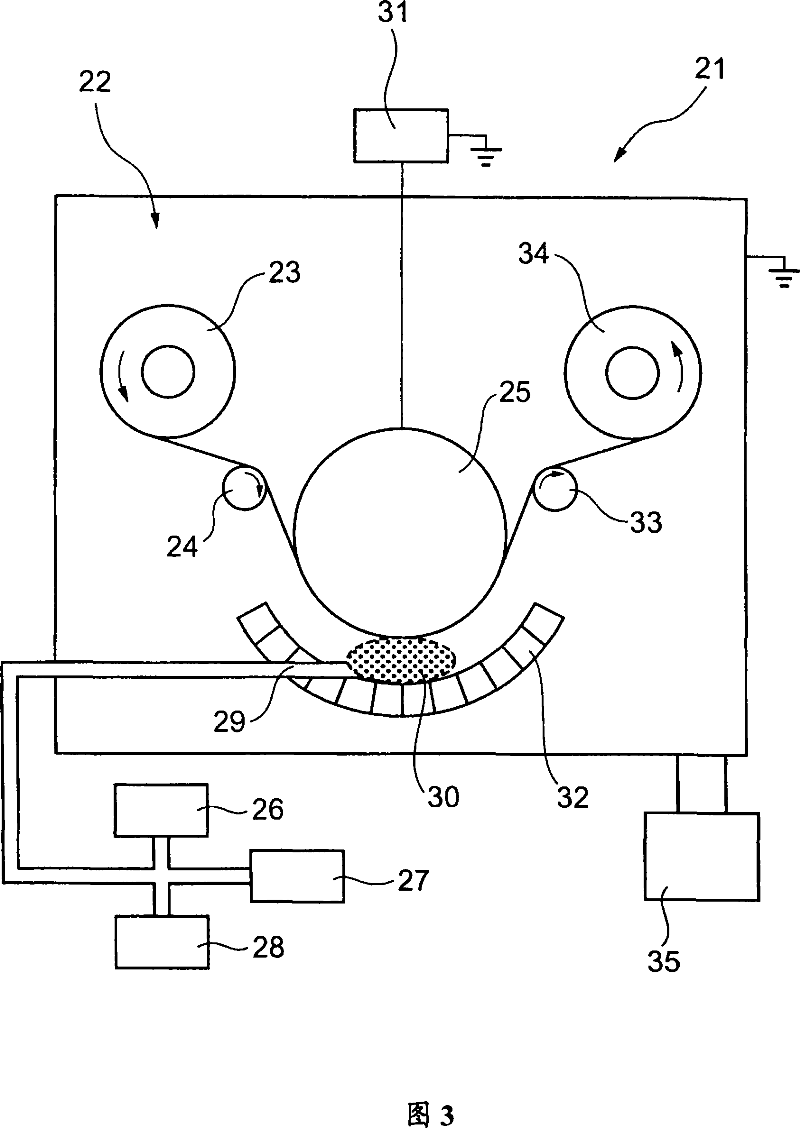

[0204] (1) Using a biaxially stretched polyethylene terephthalate film with a thickness of 12 μm, it was mounted on the delivery roll of the plasma chemical vapor deposition apparatus, and then, according to the conditions shown below, the A vapor-deposited film of silicon oxide having a thickness of 200 angstroms was formed on the corona-treated surface of the axially stretched polyethylene terephthalate film.

[0205] (deposition condition)

[0206] Evaporation surface: corona treatment surface

[0207] The gas introduced is: hexamethyldisiloxane: oxygen: helium = 1.0: 3.0: 3.0 (unit: slm)

[0208] Vacuum degree in vacuum chamber: 2~6×10 -6 mBar

[0209] Vacuum degree in evaporation chamber: 2~5×10 -3 mBar

[0210] Cooling and electrode drum power supply: 10kW

[0211] Line speed: 100m / min

[0212] Next, immediately after forming the vapor-deposited film of silicon oxide with a film thickness of 200 angstroms in the above, on the surface of the vapor-deposited film of...

Embodiment 2

[0230] (1) Use a biaxially stretched polyethylene terephthalate film with a thickness of 12 μm, install it on the delivery roll of the plasma chemical vapor deposition device, and then, according to the conditions shown below, in the above-mentioned A vapor-deposited film of silicon oxide having a thickness of 200 angstroms was formed on the corona-treated surface of the biaxially stretched polyethylene terephthalate film.

[0231] (deposition condition)

[0232] Evaporation surface: corona treatment surface

[0233] The amount of gas introduced is: hexamethyldisiloxane: oxygen: helium = 1.0: 3.0: 3.0 (unit: slm)

[0234] Vacuum degree in vacuum chamber: 2~6×10 -6 mBar

[0235] Vacuum degree in evaporation chamber: 2~5×10 -3 mBar

[0236] Cooling and electrode drum power supply: 10kW

[0237] Line speed: 100m / min

[0238] Next, immediately after forming the vapor-deposited film of silicon oxide with a film thickness of 200 angstroms in the above, on the surface of the v...

Embodiment 3

[0253] (1) Use a biaxially stretched polyethylene terephthalate film with a thickness of 12 μm, install it on the delivery roll of the plasma chemical vapor deposition device, and biaxially stretch it according to the conditions shown below. A silicon oxide vapor-deposited film with a thickness of 200 angstroms was formed on the corona-treated surface of the nylon film.

[0254] (deposition condition)

[0255] The reaction gas mixing ratio is: hexamethyldisiloxane: oxygen: helium = 1.2: 5.0: 2.5 (unit: Slm)

[0256] Arrival pressure: 5.0×10 -5 mbar

[0257] Membrane pressure: 7.0×10 -2 mbar

[0258] Line speed: 150m / min

[0259] Power: 35kW

[0260] Next, just after forming the vapor-deposited film of silicon oxide with a thickness of 200 angstroms in the above, on the surface of the vapor-deposited film of silicon oxide, a glow discharge plasma generator was used under a power of 9 kw using oxygen: argon = The mixed gas formed by 7.0:2.5 (unit: Slm), at the mixed gas p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com