Electrode rod for detecting water-level, method of detecting water-level, and method of controlling water-level

A technology of water level detection and electrode rods, applied in lighting and heating equipment, liquid level indicators for physical variable measurement, steam boiler accessories, etc., can solve problems such as damage to water pipe headers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

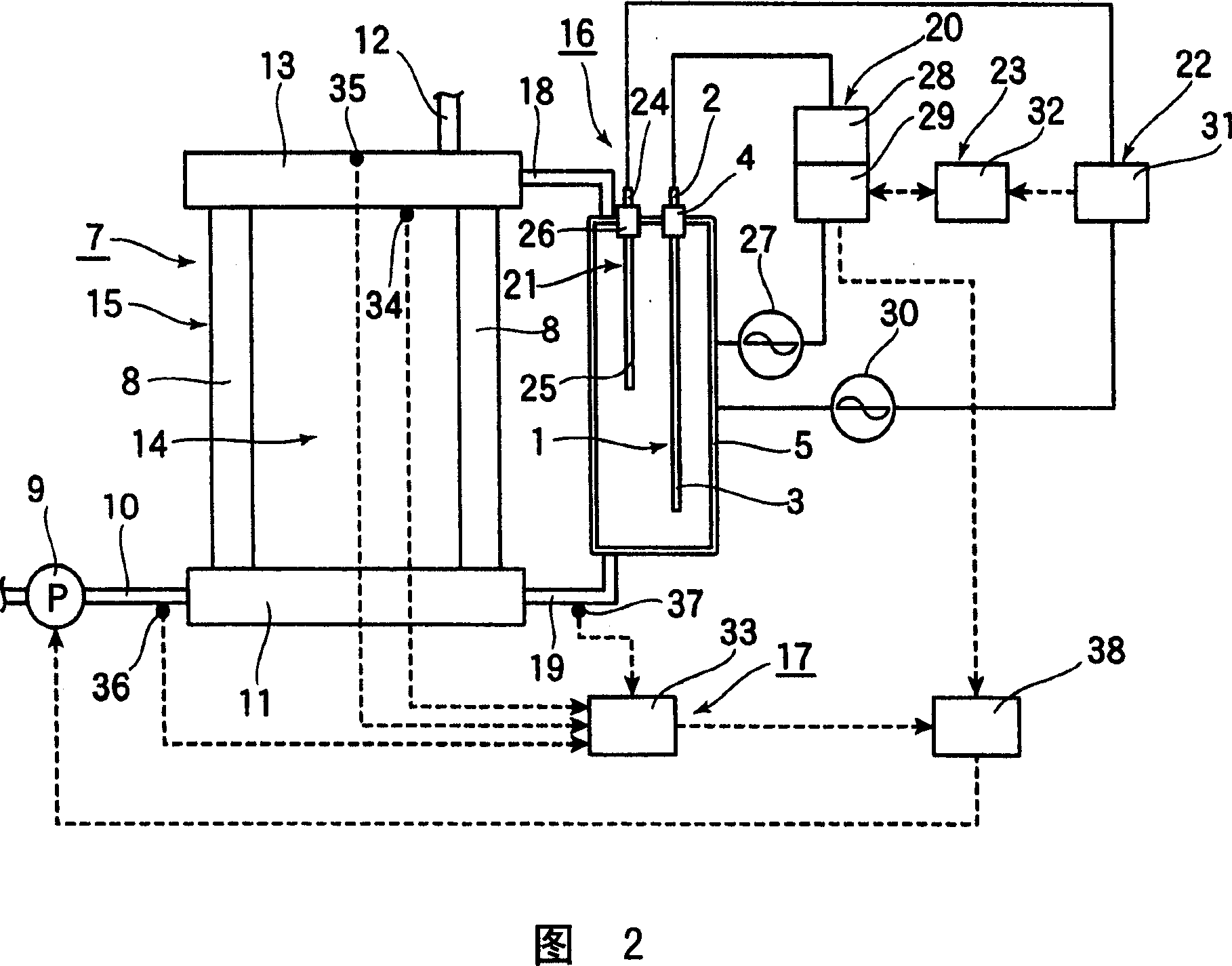

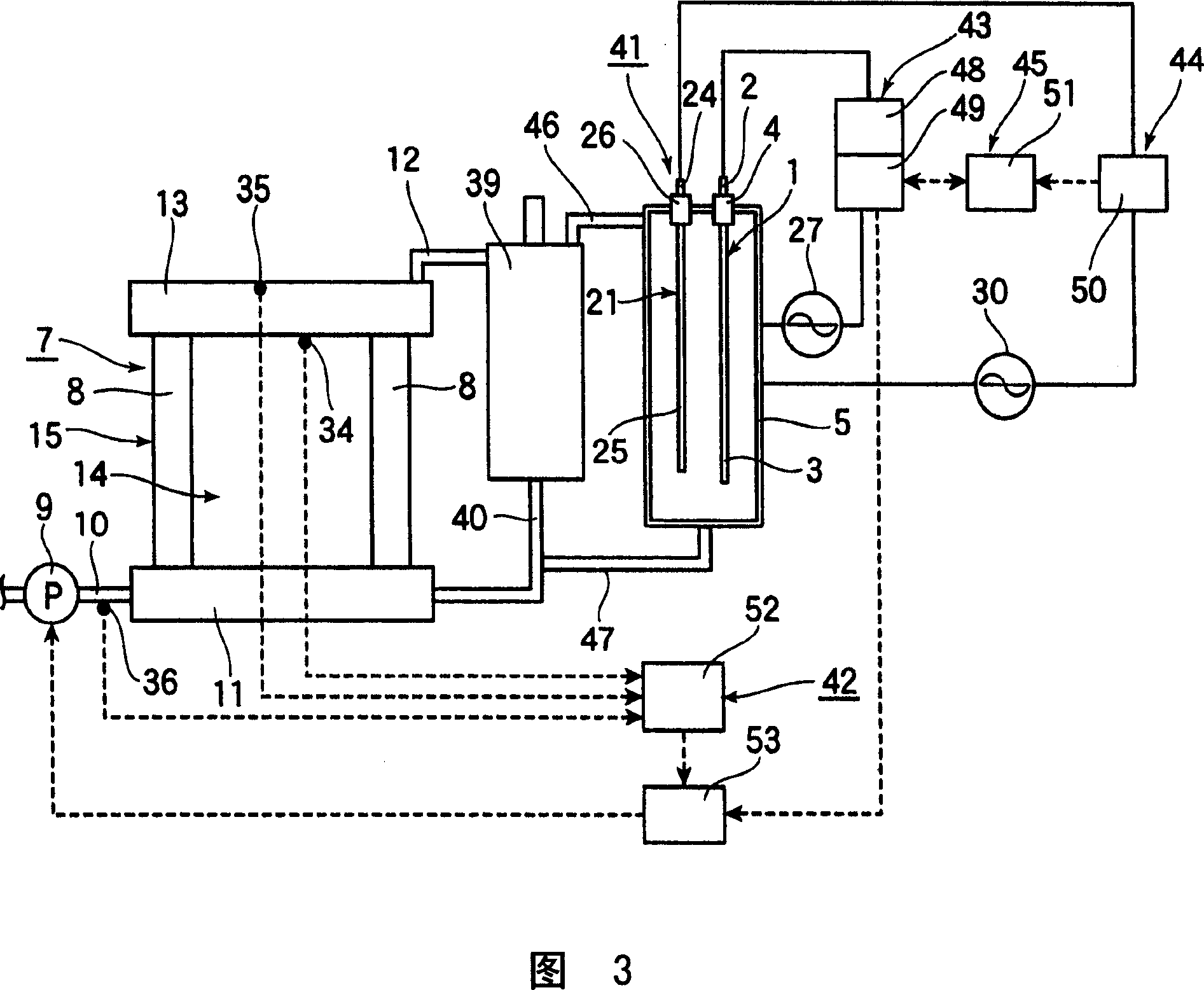

[0097] Hereinafter, the best mode for carrying out the electrode rod for water level detection, the water level detection method, the water level control method of the boiler, and the water level control method of the gas-water separator of the present invention will be described.

[0098] First, an embodiment of an electrode rod for detecting a boiler water level according to the present invention will be described.

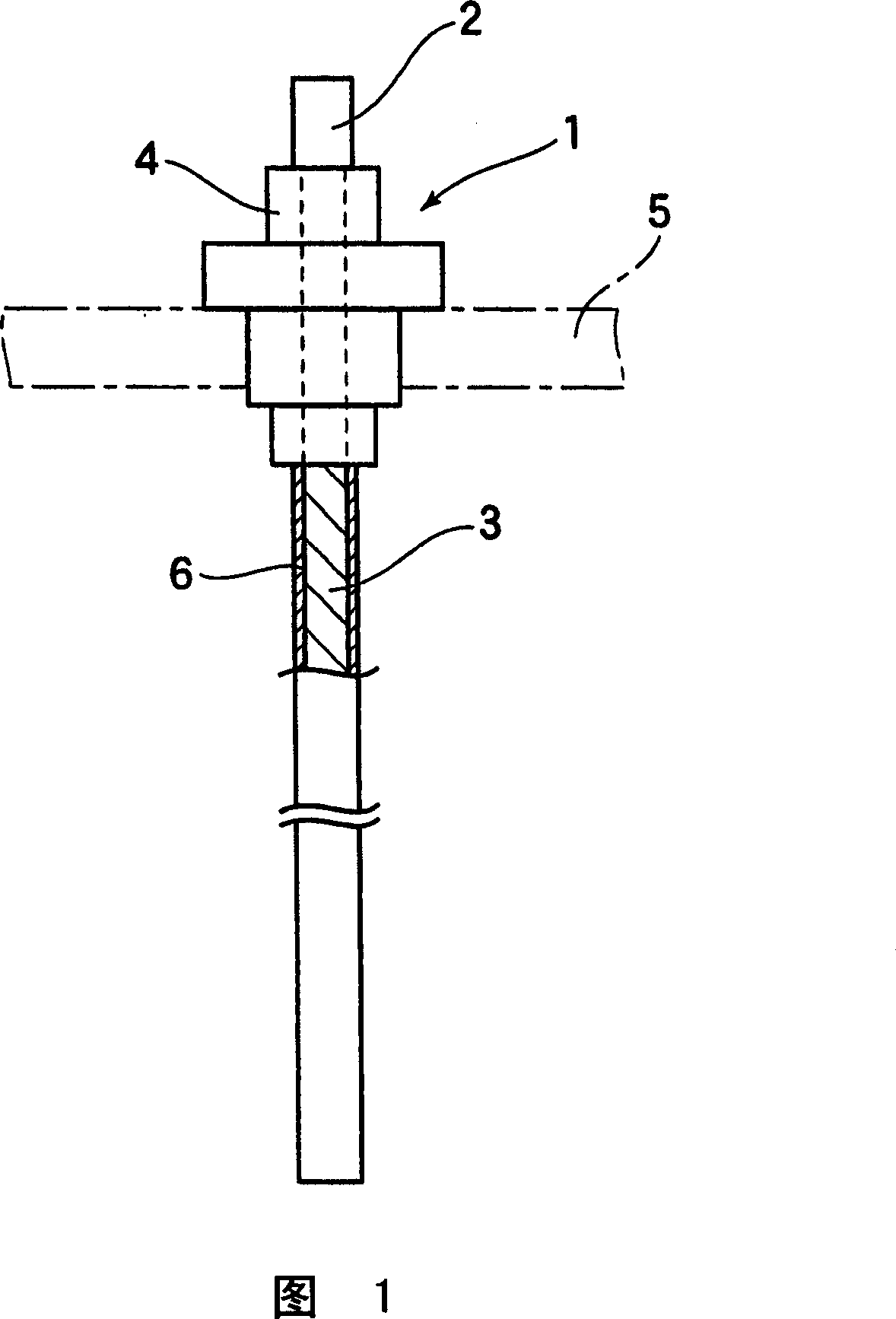

[0099] FIG. 1 is a partially cutaway front view showing an example of an embodiment of the electrode rod for water level detection according to the present invention.

[0100] The electrode rod 1 for water level detection of this example has an external power supply connection terminal part 2 on one end side, and a water level detection electrode part 3 on the other end side, is held by a cylindrical insulator 4, and is connected to an external power supply via the insulator 4. The terminal portion 2 protrudes to the outside of the metal container 5 , and the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com