Method and device for the production of plates of thermoplastically extruded synthetic materials

A thermoplastic, sheet technology, used in optics, instruments, light guides, etc., can solve the problems of expensive preparation, cost-consuming, and inability to guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation of the method for preparing a sheet from thermoplastic extruded plastics according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments, Structure, characteristic and effect thereof are as follows in detail.

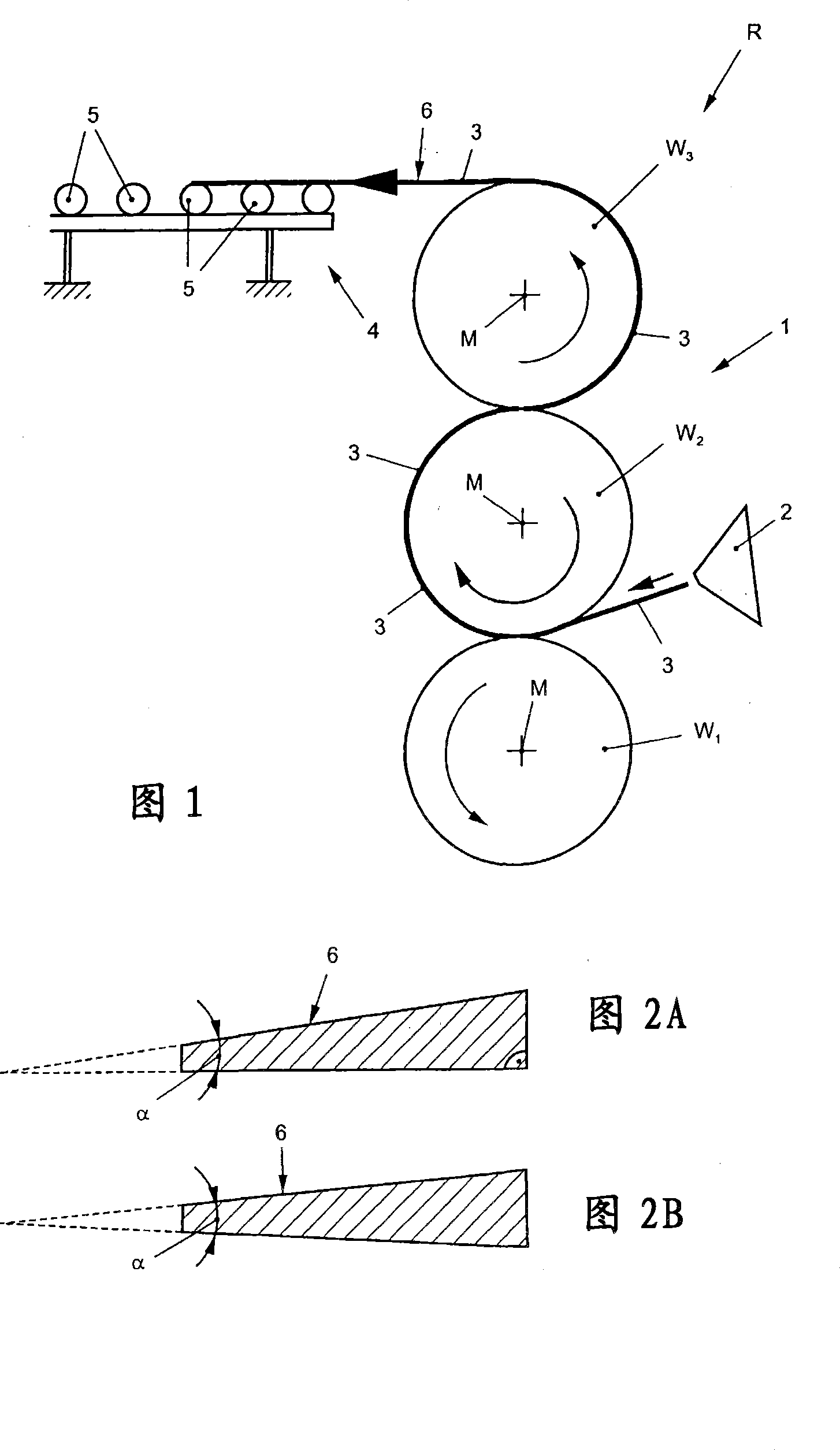

[0058] Referring to FIG. 1, the device R for thermoplastically extruding plastics 3, especially sheets 6, has a calender 1 which is again only schematically drawn and which is designed in the preferred present embodiment as In the form of a three-roll calender with rolls W1, W2 and W3. Inserted between the rolls W1 and W2 is a thermoplastic 3 extruded through an extrusion nozzle 2 . The plastic material 3 flows continuously around the roller W2 and around the other roller W3 onto a raceway 4 with rollers 5 , which is only indicated here...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com