Method for compressive shrinking and rubber blanket shrinking system

A rubber blanket, mechanical compression technology, applied in the direction of adding compressed water, textile and papermaking, fabric surface trimming, etc., can solve problems such as cooling rubber blankets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

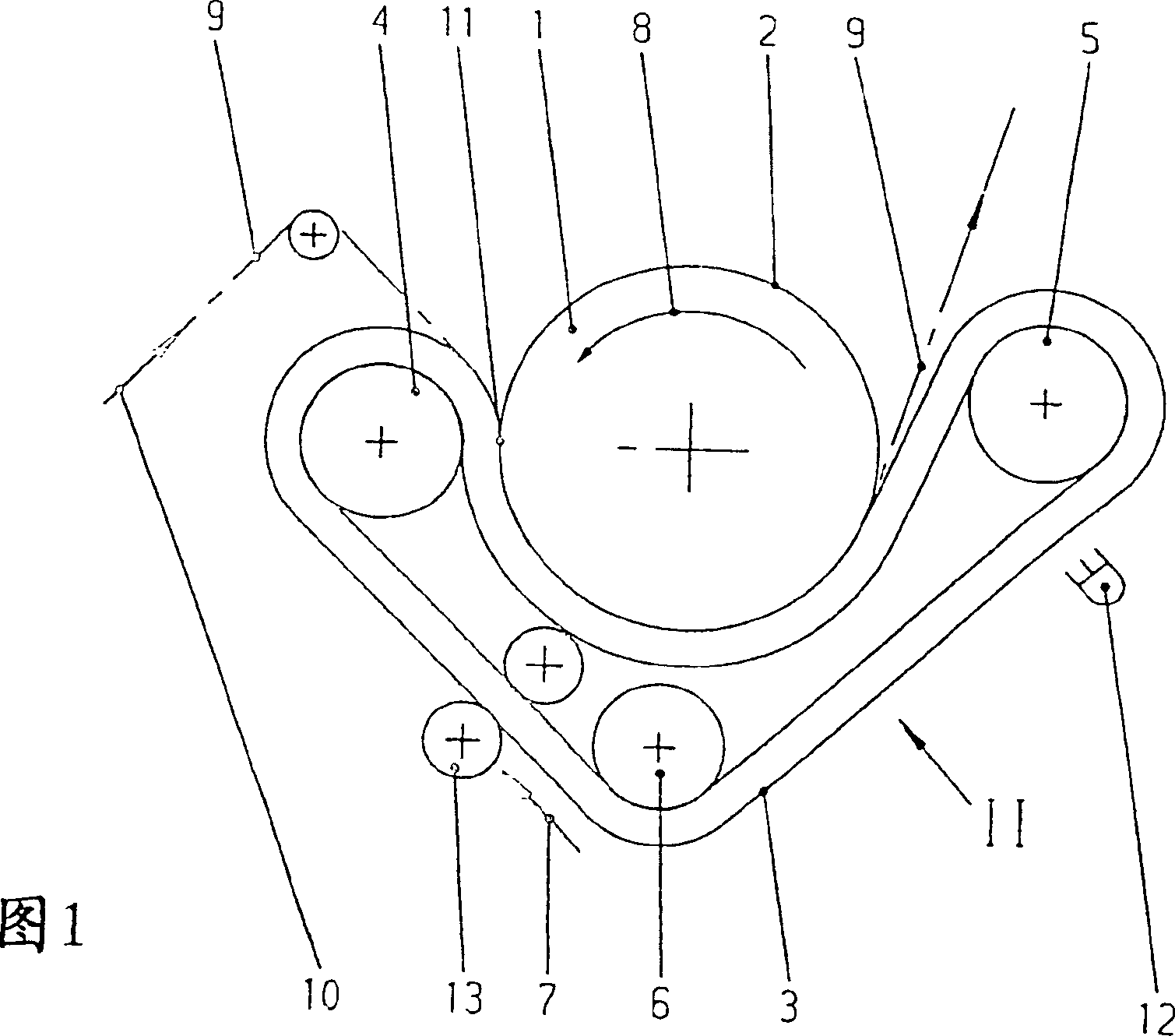

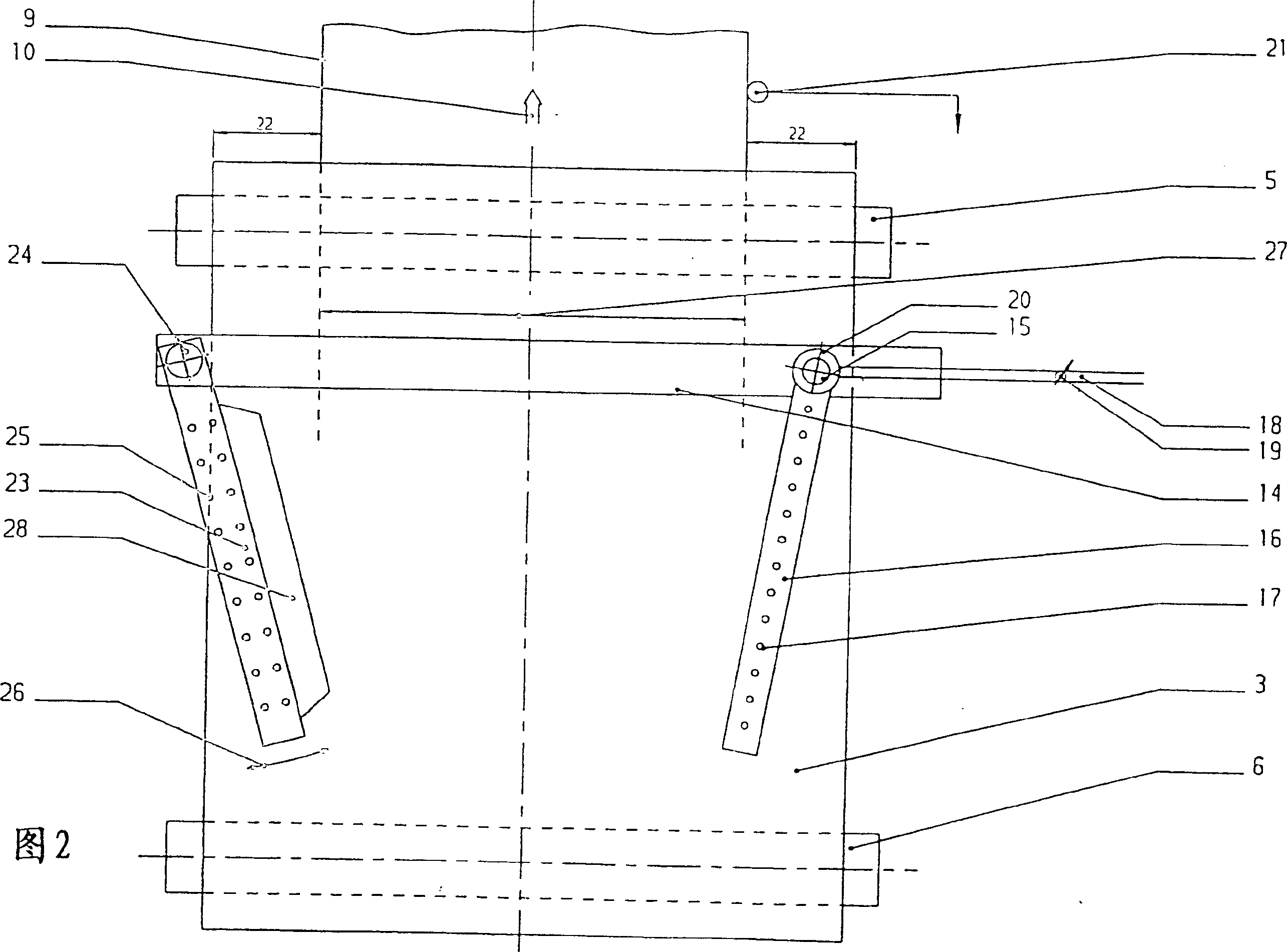

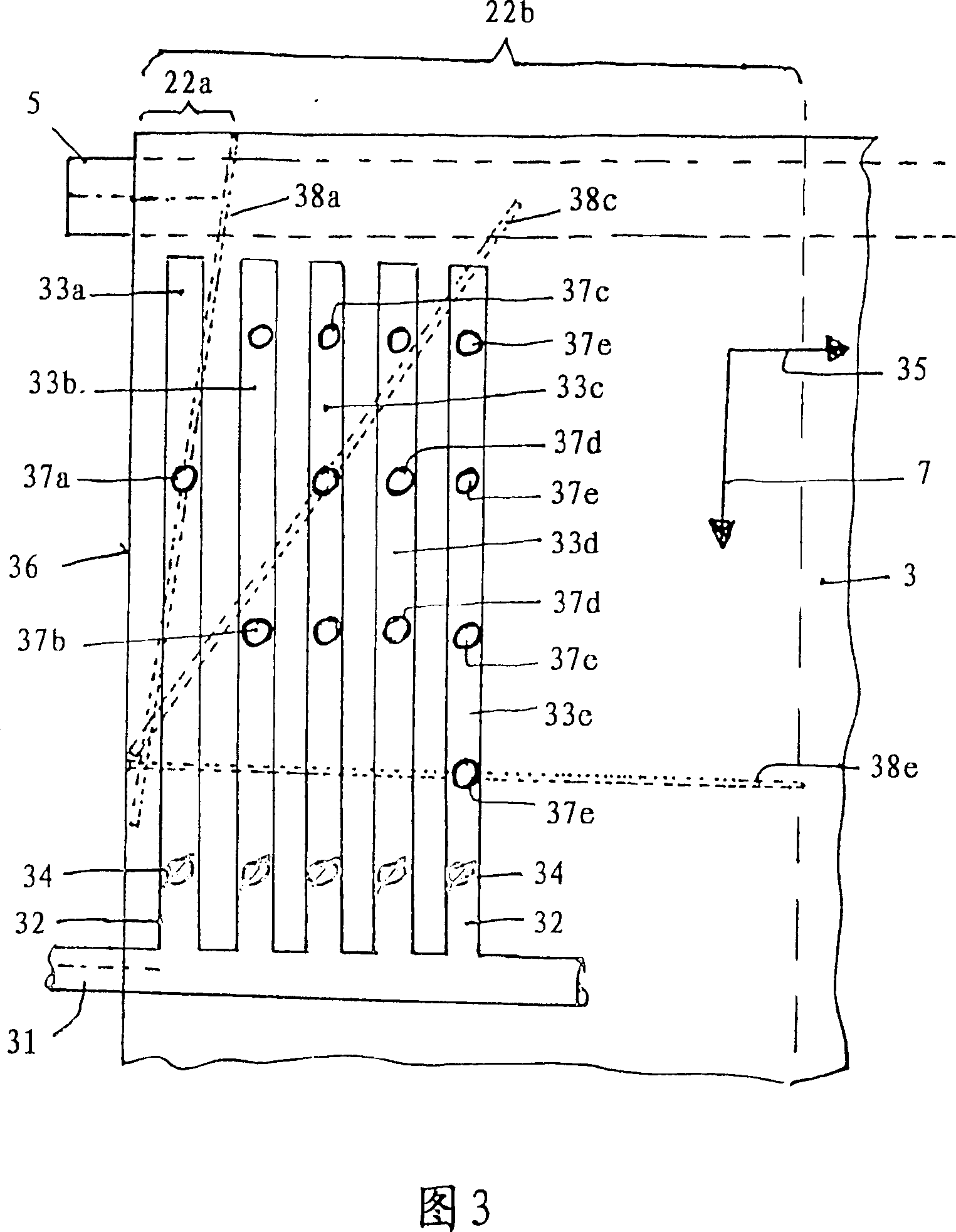

[0024] Figure 1 shows a longitudinal section (perpendicular to the marked roller axis) of a rubber belt shrinking device. The device consists in principle of a heated main drum 1 , onto the peripheral outer surface 2 of the main drum 1 , of a circulating rubber blanket 3 which is tensioned in its longitudinal direction. The rubber blanket 3 is guided in a marked running direction 7 via so-called pressure rollers 4 and guide or deflection rollers 5 , 6 . The corresponding deflection 8 of the main drum 1 is also indicated by an arrow. The textile web 9 to be preshrunk is passed along the indicated conveying direction 10 via the pressure roller 4 into a so-called shrinking nip 11 , where mechanical shrinking takes place.

[0025] The mechanically produced pre-shrinking is effected by the heated main cylinder 1 while the fabric web 9 is shaped by the compression of the fabric web 9 on the peripheral outer surface 2 by means of the rubber blanket 3 . In order to achieve the pre-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com