Method for operating air-jet spinning machine with cooling arrangement.

A technology of air-jet spinning machine and cooling device, which is applied in the direction of continuous winding spinning machine, spinning machine, open-end spinning machine, etc., which can solve the problem of weakening surface quality, poor airflow of spinning nozzle, and reducing yarn line quality etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

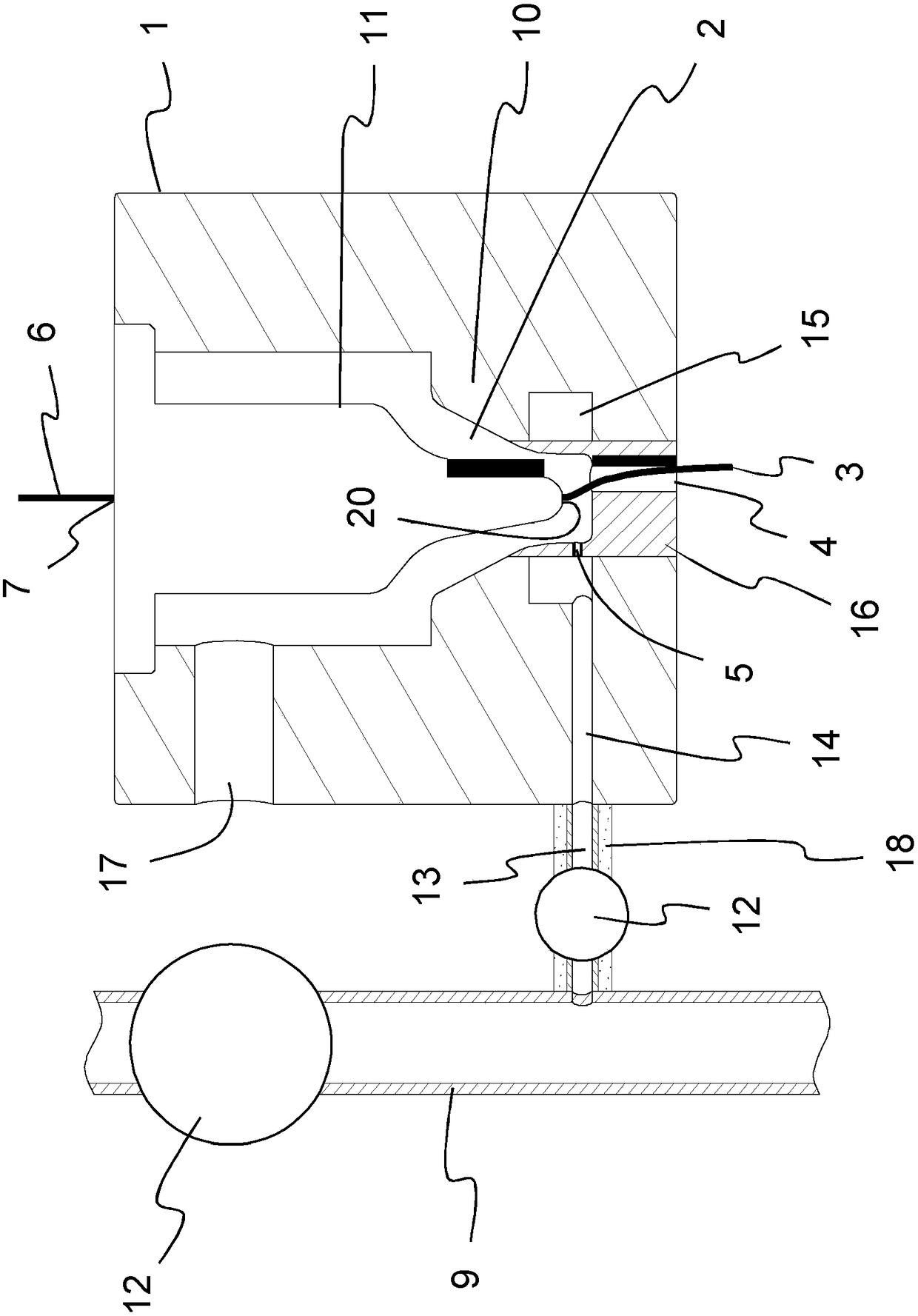

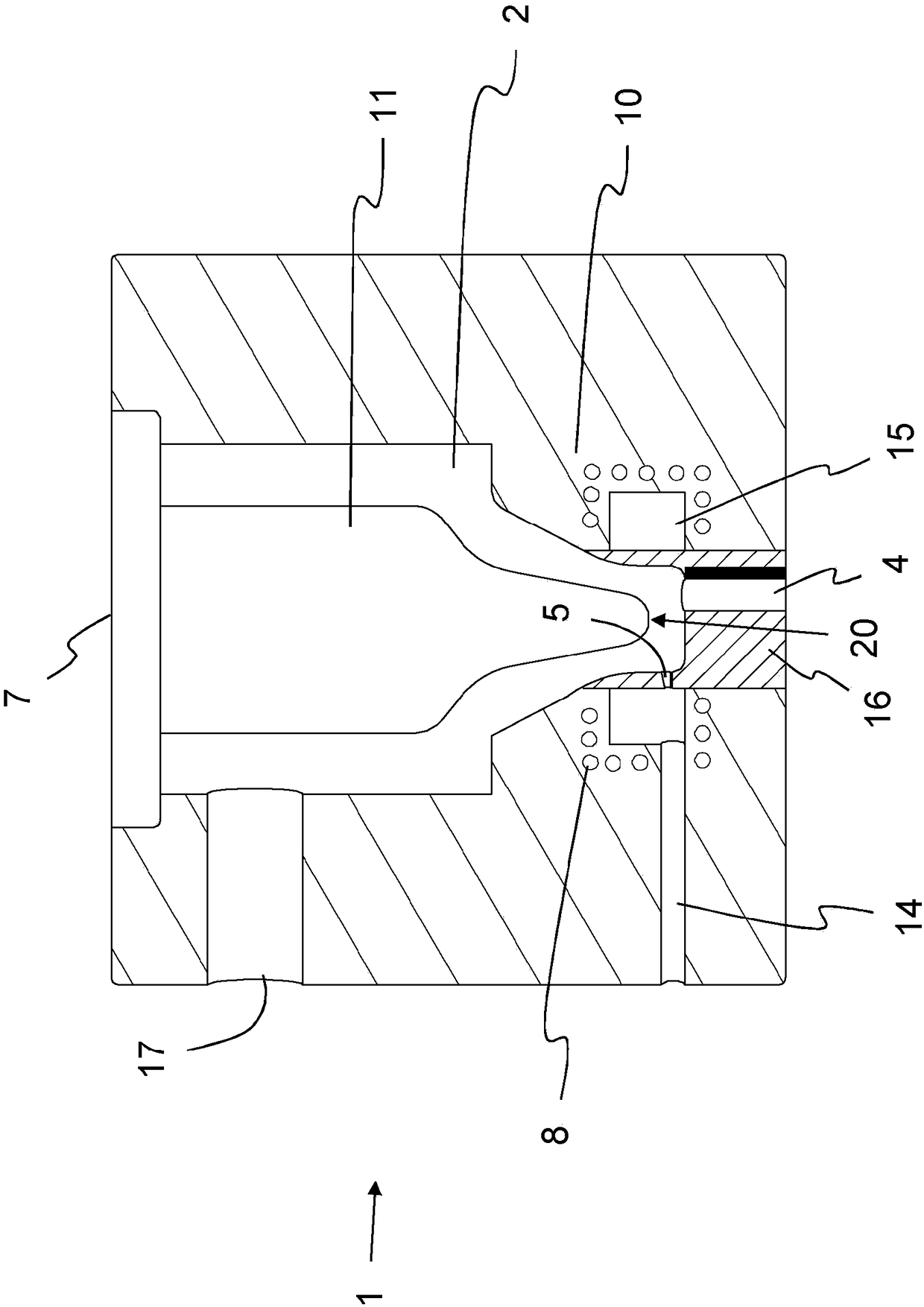

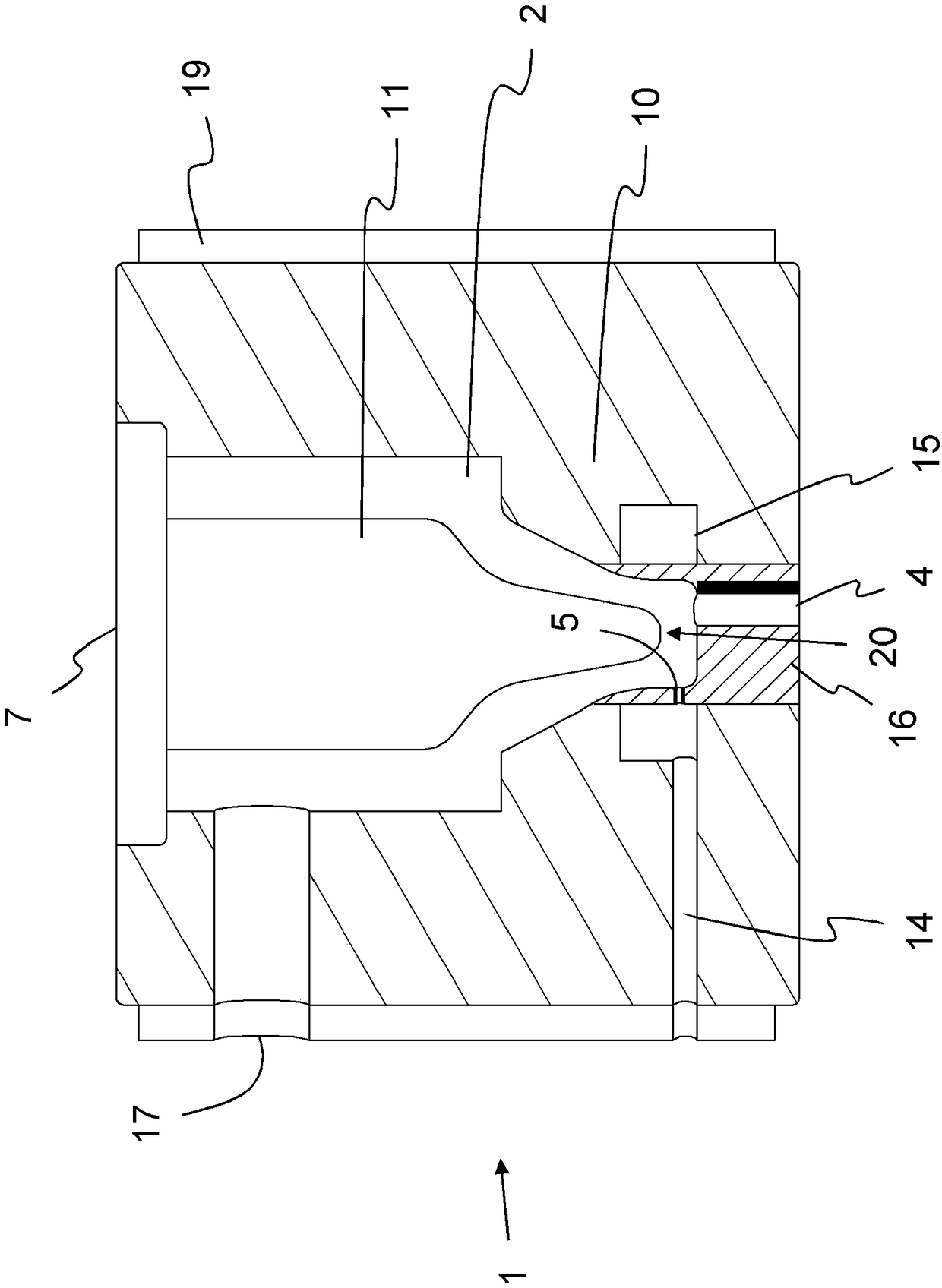

[0035] figure 1 is a partial sectional view of a spinning nozzle 1 of an air-jet spinning machine, wherein this air-jet spinning machine can of course have a plurality of spinning nozzles 1 of this type. The spinning nozzle 1 has an inlet 4, which can be formed, for example, by a separate fiber guiding element 16, through which the fiber material to be spun, usually in the form of a drawn fiber bundle 3, enters the so-called vortex of the spinning position. The whirl chamber 2 implements the spinning process in the true sense again in this whirl chamber.

[0036] Drawing is usually carried out by means of a drafting device (not shown) upstream of the fiber guiding element 16 of the respective spinning position of the air-jet spinning machine, by means of a pair of take-off rollers also not shown to draw the drawn fibers The bundle 3 is drawn off from the drafting device (alternatively, it can also be drawn off by other components, such as a storage drum).

[0037] After pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com