Kitchen range waste heat recovering energy conserving system and water-level controlling heat insulation device

A waste heat recovery and energy-saving system technology, applied to water heaters, fluid heaters, heat exchangers, etc., can solve the problem of long time for water to reach the required temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

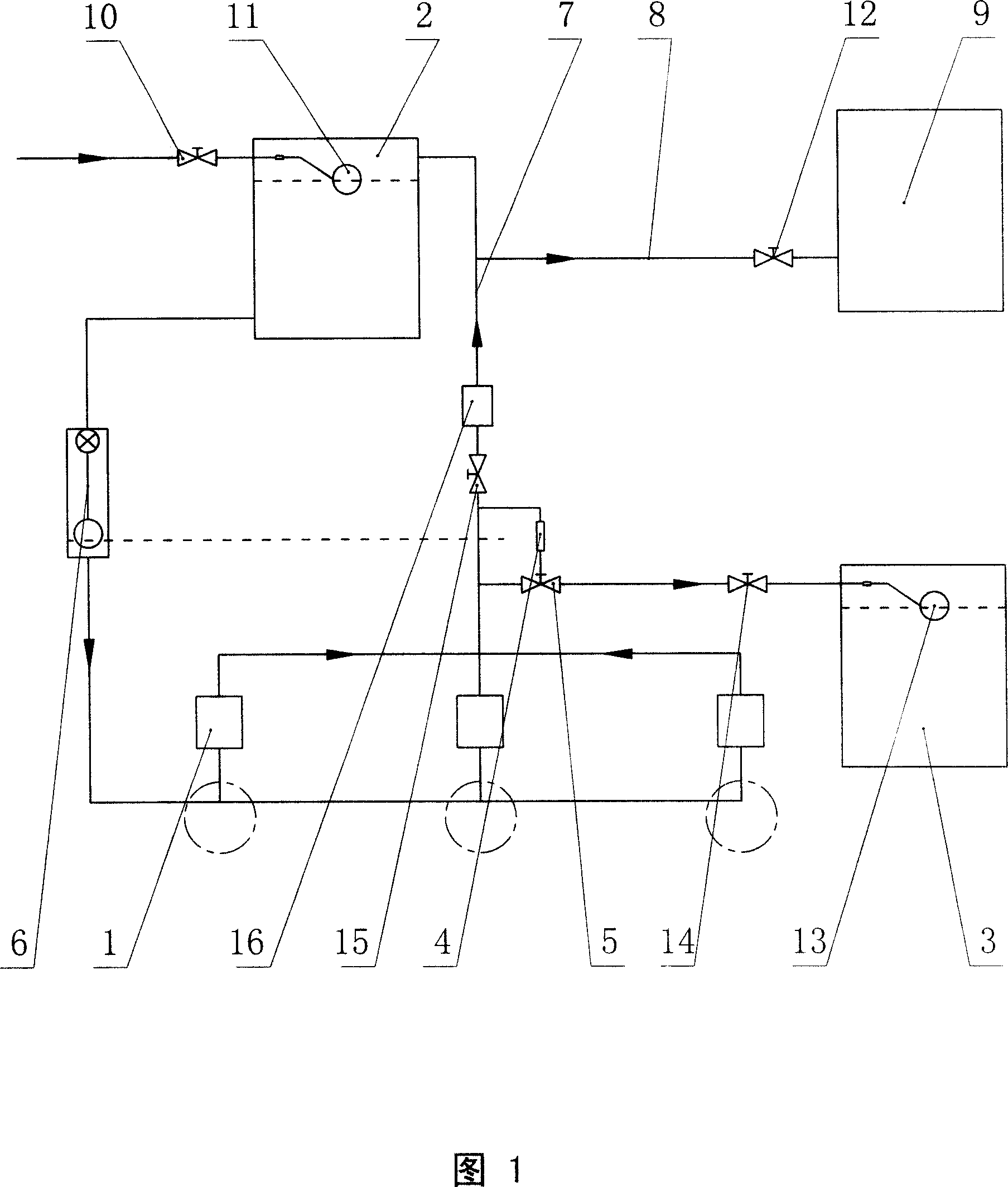

[0020] As shown in FIG. 1 , the present invention includes a heat exchanger 1 , a water tank 2 , a thermal insulation hot water tank 3 , a water level control and heat insulation device 6 , and a steam pipe 7 .

[0021] According to the number of stoves in the dining place, at least one of the heat exchangers 1 is arranged at the outlet of the stove flue, and a plurality of the heat exchangers 1 can be connected in series or in parallel through pipes. The water tank 2 is connected with the water source through the water inlet pipe. In order to prolong the service life of the system, the water source adopts the treated soft water source. The water inlet pipe is provided with a water inlet valve 10 and the water tank 2 is provided with a float valve 11 to control the water tank The highest water level in 2. The water tank 2 is connected to the heat exchanger 1 through a water outlet pipe, and the water level control and heat insulation device 6 is arranged on the water outlet pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com