Peroxide vapor sulfurizing process for EPDM rubber pipe

A hose peroxide and steam technology, which is applied to tubular articles, other household appliances, household appliances, etc., can solve the problems of high production cost and complex equipment, and achieve the effects of sufficient vulcanization, lower production costs, and improved appearance quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

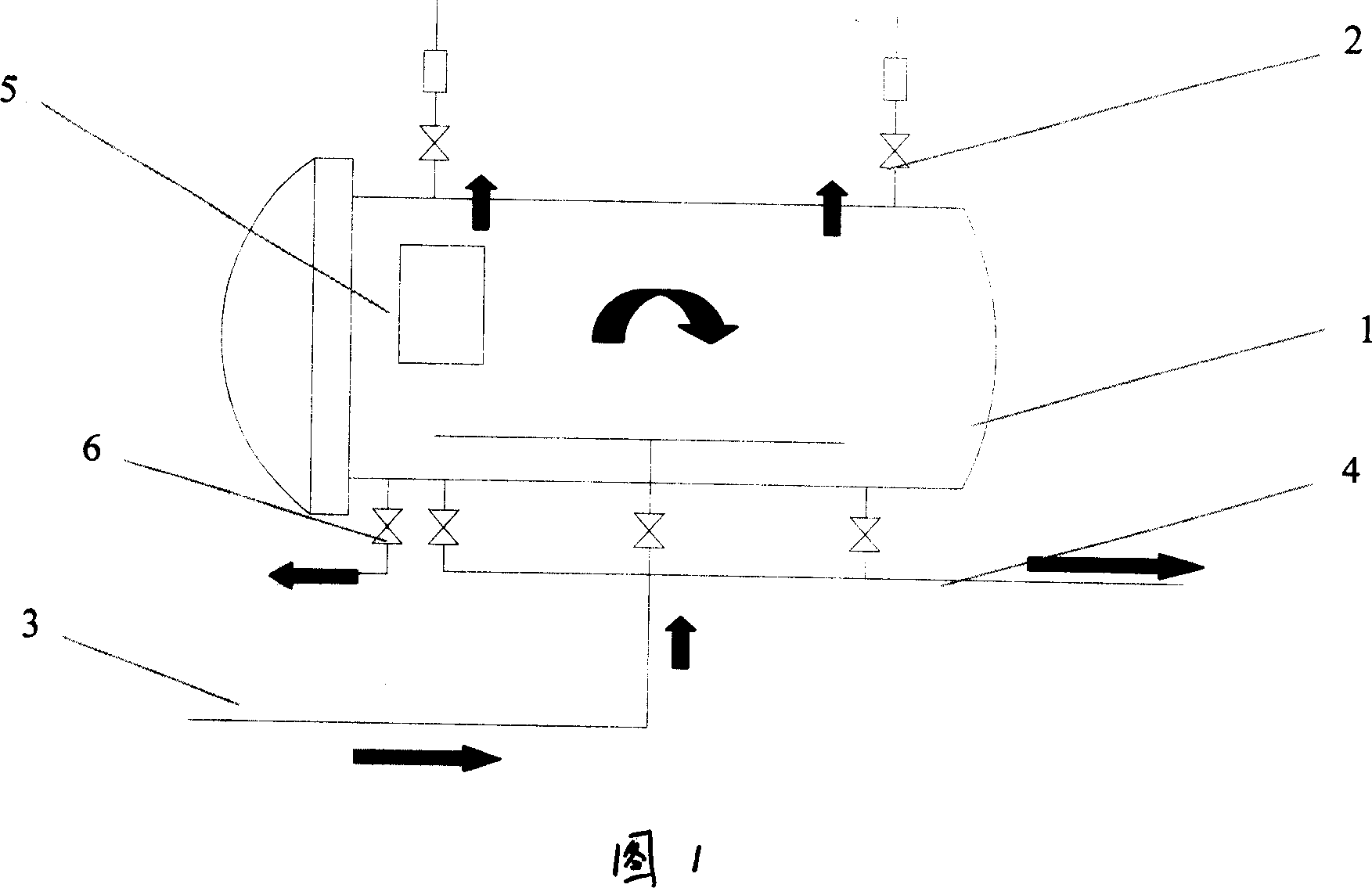

[0014] See attached picture.

[0015] 1. Vulcanization tank, the size of the tank is Ф1500×3000. 2. Automatic exhaust air valve (thermostatic exhaust valve for steam, it is recommended to use the product of Japan TLV company). 3. The steam inlet pipe (specification DN60), the steam inlet is in the middle of the autoclave, and after entering the autoclave, a steel pipe is connected to guide the steam evenly into all parts of the autoclave. The longer the length of the steel pipe, the better. 4. Exhaust pipe (specification DN60), the exhaust pipe is installed near both ends of the vulcanization tank, and exhausts steam at the same time. 5. The control cabinet centrally collects, measures and controls parameters such as oxygen exhaust time, heating time, vulcanization time, oxygen exhaust temperature, vulcanization temperature, oxygen exhaust pressure, and vulcanization pressure. 6. Drain valve (it is recommended to use the product of Japan TLV company). The steam trap can quic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com