Technological process of back pouring percolate to speed stabilization of old landfill site

The invention relates to a technology for a landfill and a process method, which is applied in the field of leachate recharge to accelerate the stabilization process of an old landfill, and can solve the problems of difficulty in meeting the requirements for the quality of the treated effluent, high construction and operation costs, and poor biodegradability. To achieve the effect of improving effluent quality, simple and easy construction, and accelerated degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Pilot test of a bioreactor landfill in South China

[0043] Since 2002, Tsinghua University has carried out a pilot-scale anaerobic bioreactor landfill stabilization study using four 30t test columns in a landfill in the south as the research object. Frequency, under the condition of leachate recharge, the change of water quality of the leachate outflow from the test column, the generation of landfill gas and the degradation of landfill waste. According to actual measurements, the wet recombination of domestic waste in Shenzhen is: kitchen waste 67.01%, bamboo wood 3.71%, fabric 2.30%, paper 2.62%, foam 1.76%, metal 0.86%, plastic and rubber 19.90%, glass and ceramics 1.83%. Kitchen waste mainly contains easily degradable organic matter such as cellulose and hemicellulose, which can be degraded after one to two years, while organic matter such as bamboo and wood is mainly composed of lignin, which is difficult to degrade.

[0044] The three recharge test columns R1, R2...

Embodiment 2

[0047] Closure and remediation project of an old garbage dump in the south

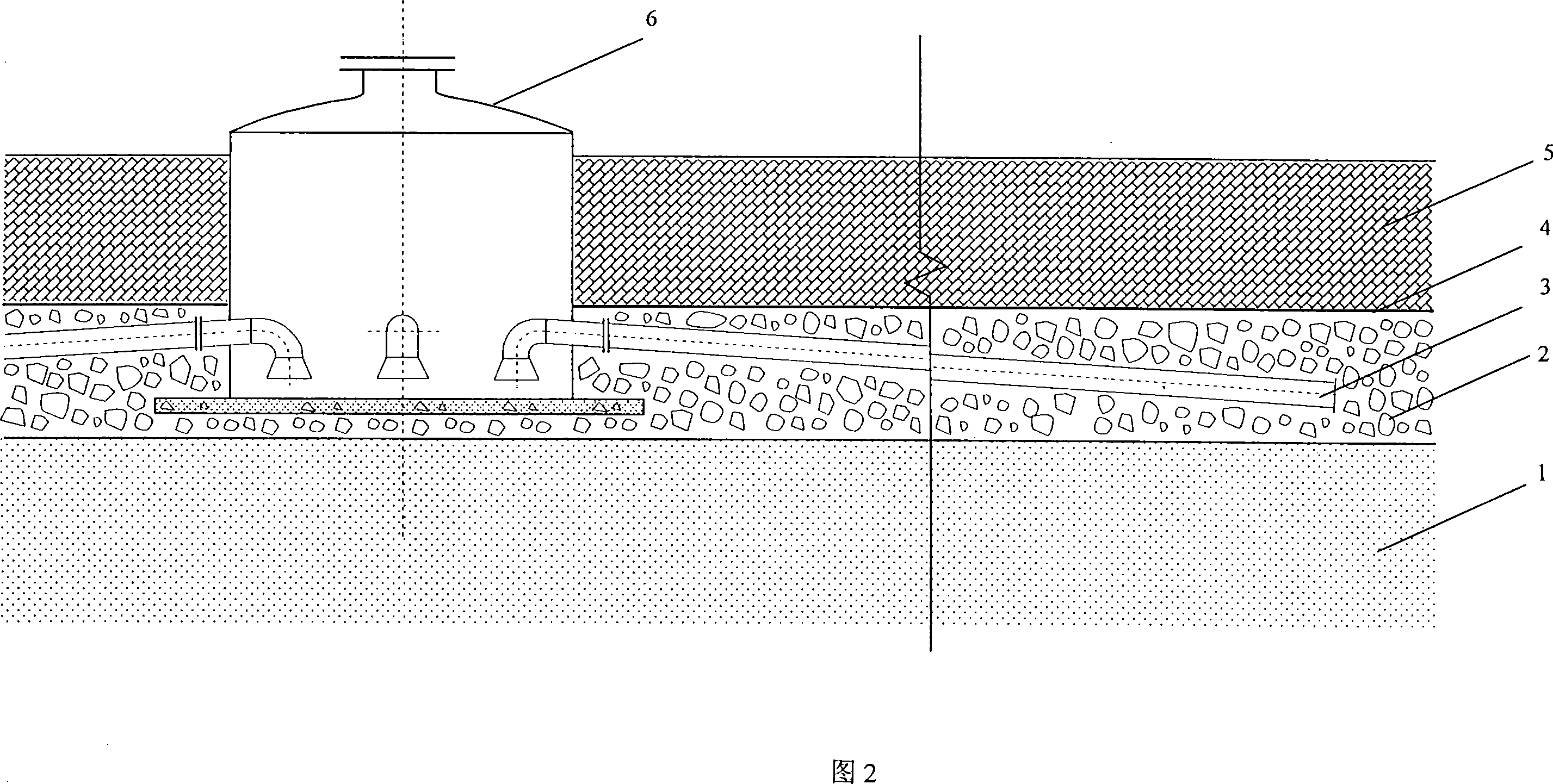

[0048] A landfill in the south, with a service life of 10 years and a total landfill volume of 1.73 million m 3 , the landfill area is 81,500 m 2 . The landfill was closed in 2005. HPDE membrane was used as the anti-seepage layer on the surface, and there were drainage and flood interception engineering facilities in the site, and an air guide system.

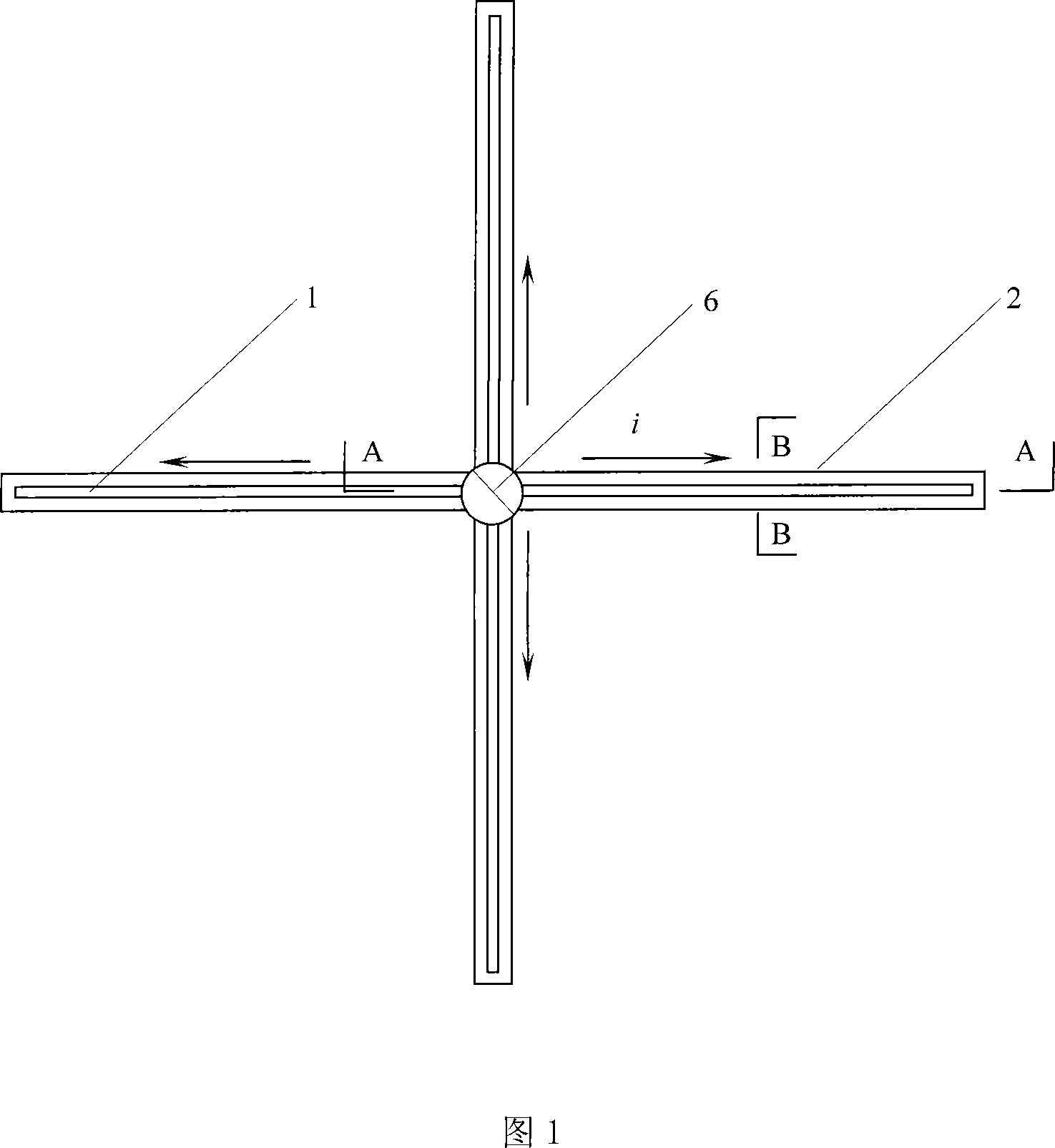

[0049] According to field data, 7 horizontal recharge units are used for leachate recharge. After one year of recharging, the results showed that the quality of the leachate effluent reached the national third-level standard for comprehensive sewage discharge, and the degree of waste degradation was significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com