SOI compound covariant layer underlay with the Ni Hafnium middle layer

An intermediate layer, hafnium nitride technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problem of weak coordination of mismatching strain of thin single crystal silicon layer, inability to overcome interface chemical reaction or interdiffusion of interface components, surface Large undulations and other problems, to achieve good mismatch strain coordination effect, superior photoelectric performance, and improve the effect of growth quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

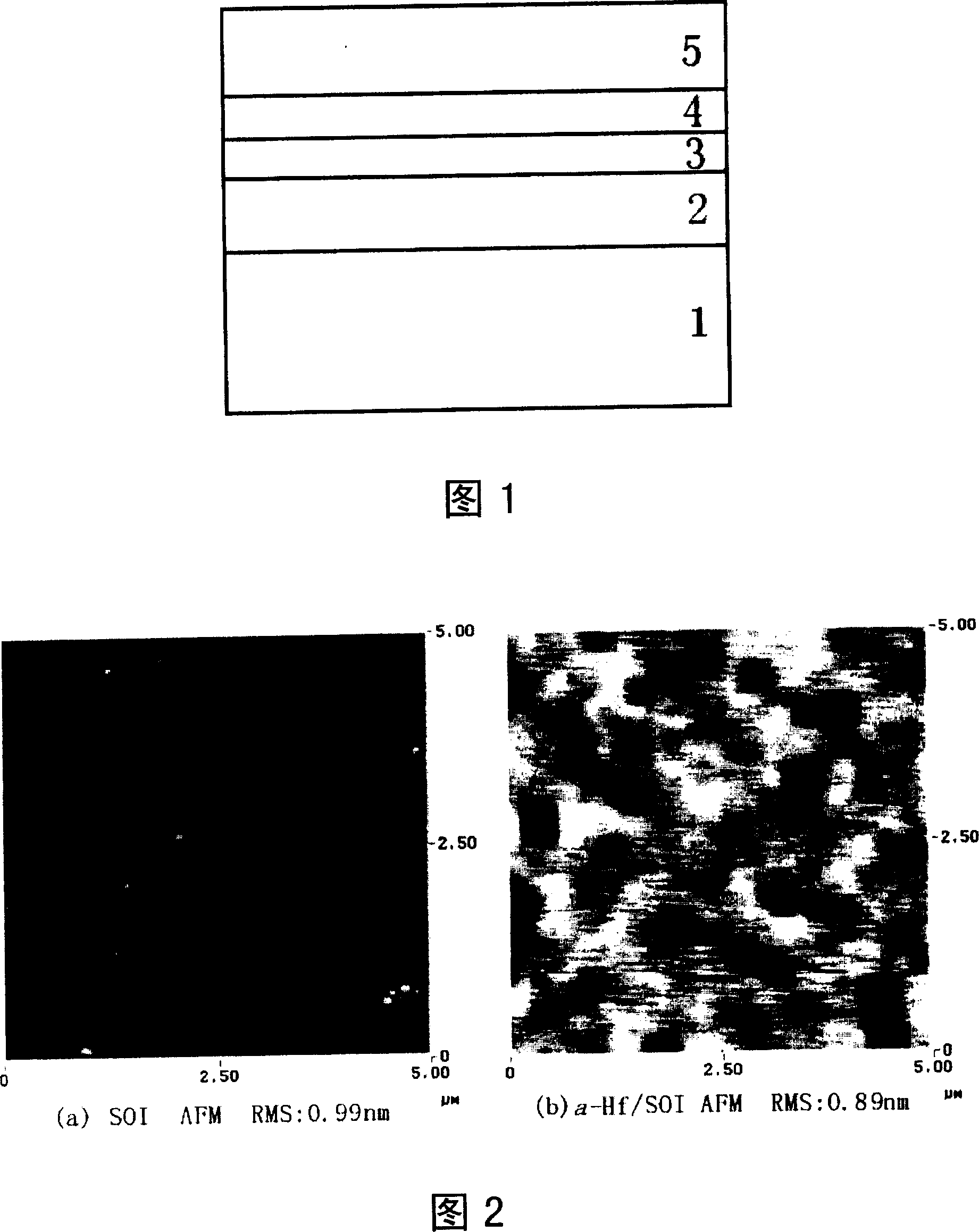

[0043] (1) A conventional SOI covariable substrate is selected for the preparation of an SOI type composite covariable layer substrate. Figure 1 is a schematic structural diagram of the substrate, and the main technical parameters are shown in Table 1.

[0044] Table 1: Main Technical Parameters of SOI Composite Covariable Layer Substrates

[0045]

SOI

composite

covariant

layer substrate

SOI

covariant

Substrate

the bottom

Supporting substrate

1

Material

Silicon (Si)

thickness

(μm)

300-

500

the crystal

quality

single crystal

middle

uncoupling layer

2

Material

(SiOx)

thickness

(nm)

200-

600

the crystal

quality

amorphous o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com