Rectangular cross section stranded conductor and fabrication method and apparatus thereof

A rectangular cross-section, wire technology, applied in the direction of conductors, insulated conductors, cable/conductor manufacturing, etc., can solve the problems of oxidation protection layer damage, labor intensity of workers, uneven gap, etc., to reduce the probability of high-voltage discharge, worker labor The effect of small strength, easy and quick operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

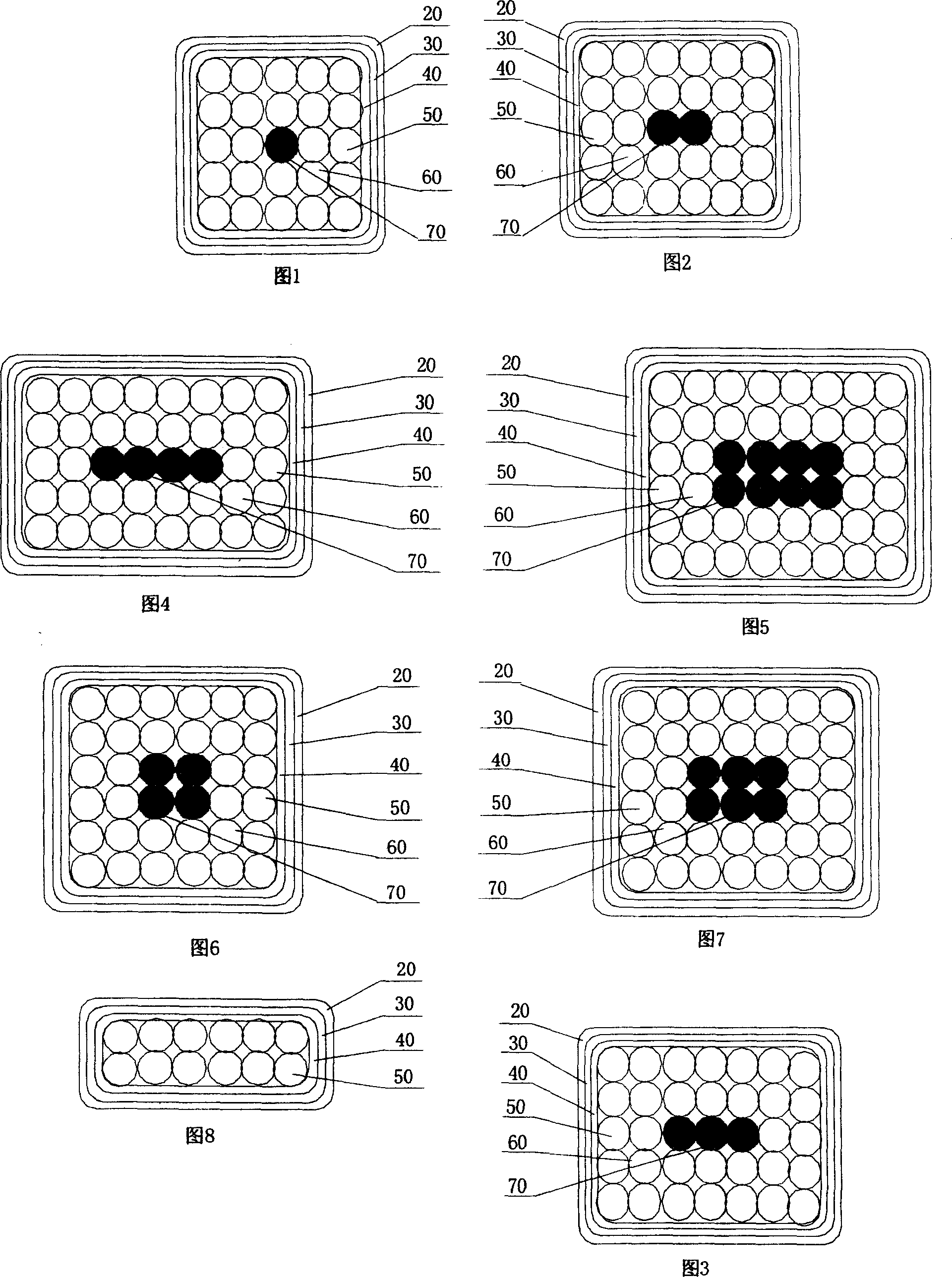

[0045] See Figures 1 to 8: 8 winding wires with different arrangement structures are listed in the figure. Layer insulation 20.

[0046] There are three technical difficulties in producing the winding wire. One is how to make the wire cores arranged regularly and the deformation as small as possible when the wires are formed, so as to ensure a regular rectangular cross-section. The second is how to prevent the surface cores from being scratched when the wires are formed. There are no burrs, and the oxidation protection layer is not damaged; the third is to choose what insulating material to meet the technical requirements of AC 1000kV and DC ±800kV dry-type reactors. Now it is described as follows:

[0047] 1. To make the wire core structure of the wires arranged in an orderly and regular manner, there are two technical keys.

[0048]1. The core structure design of the target product. Not all conductors of any structure can be pressed into a regular arrangement, only those ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com