Resin composite copper foil, printed wiring board, and production process thereof

A printed circuit board and resin composite technology, applied in the direction of multilayer circuit manufacturing, printed circuit components, printed circuit secondary processing, etc., can solve problems such as heat resistance problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

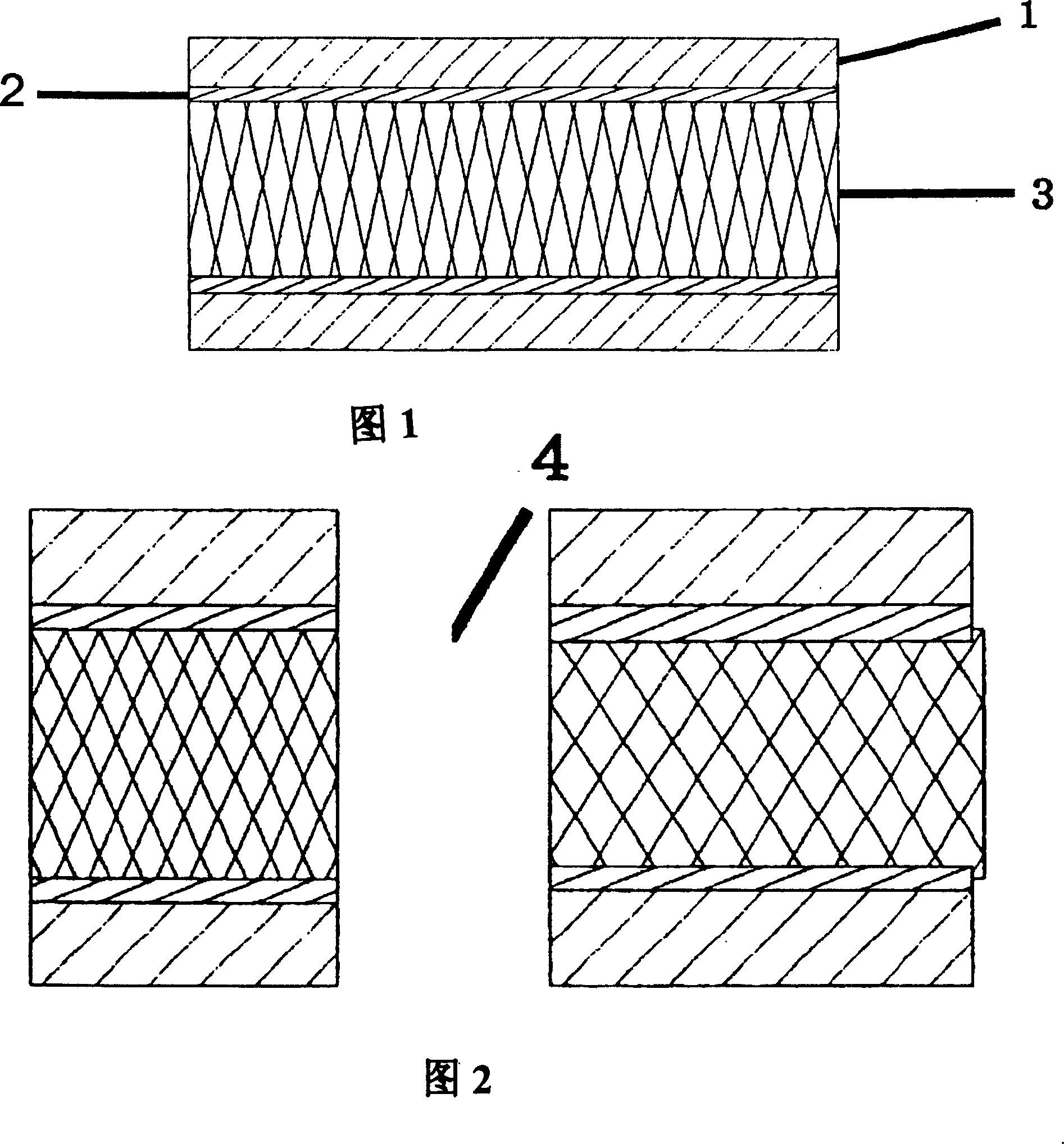

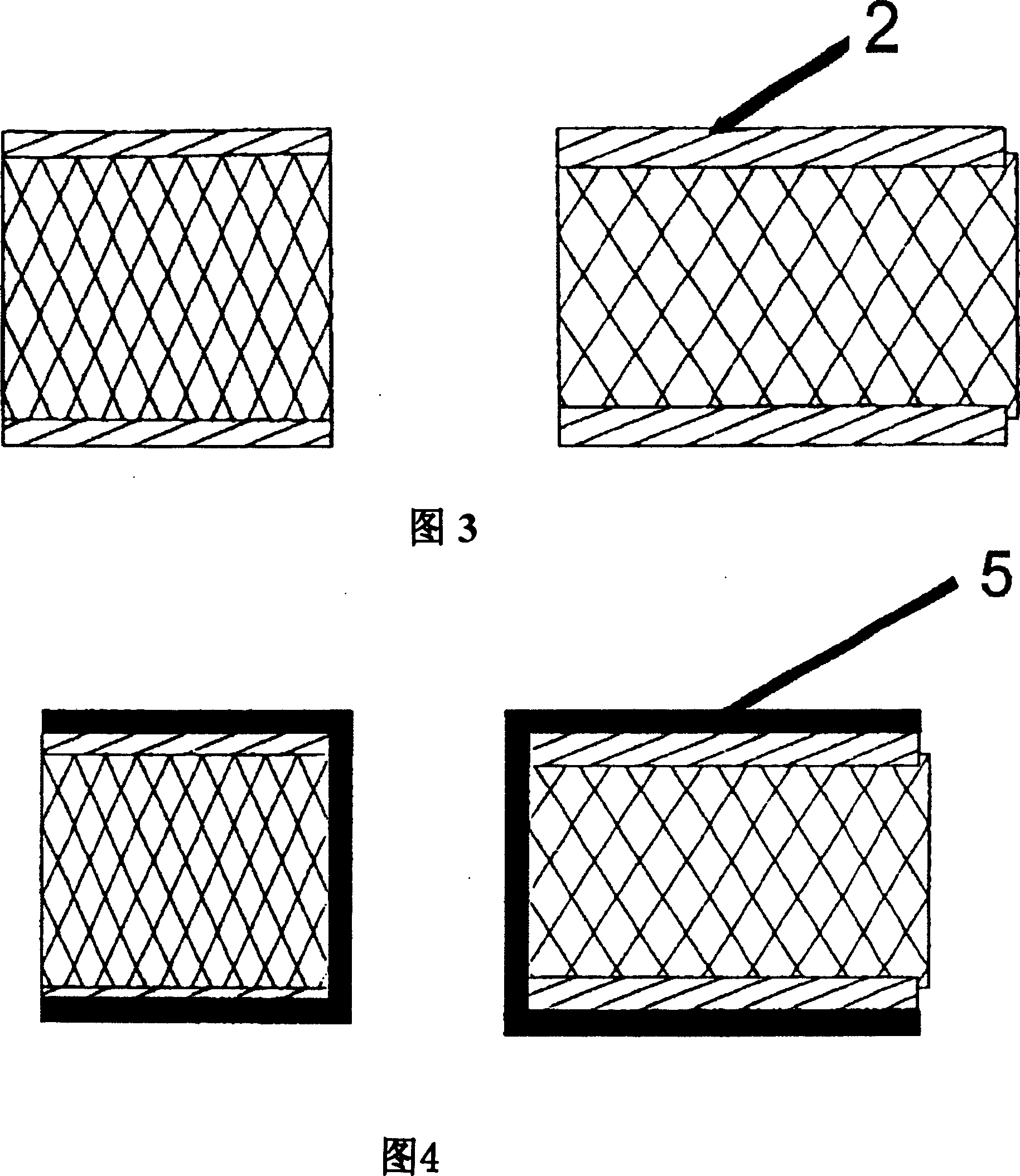

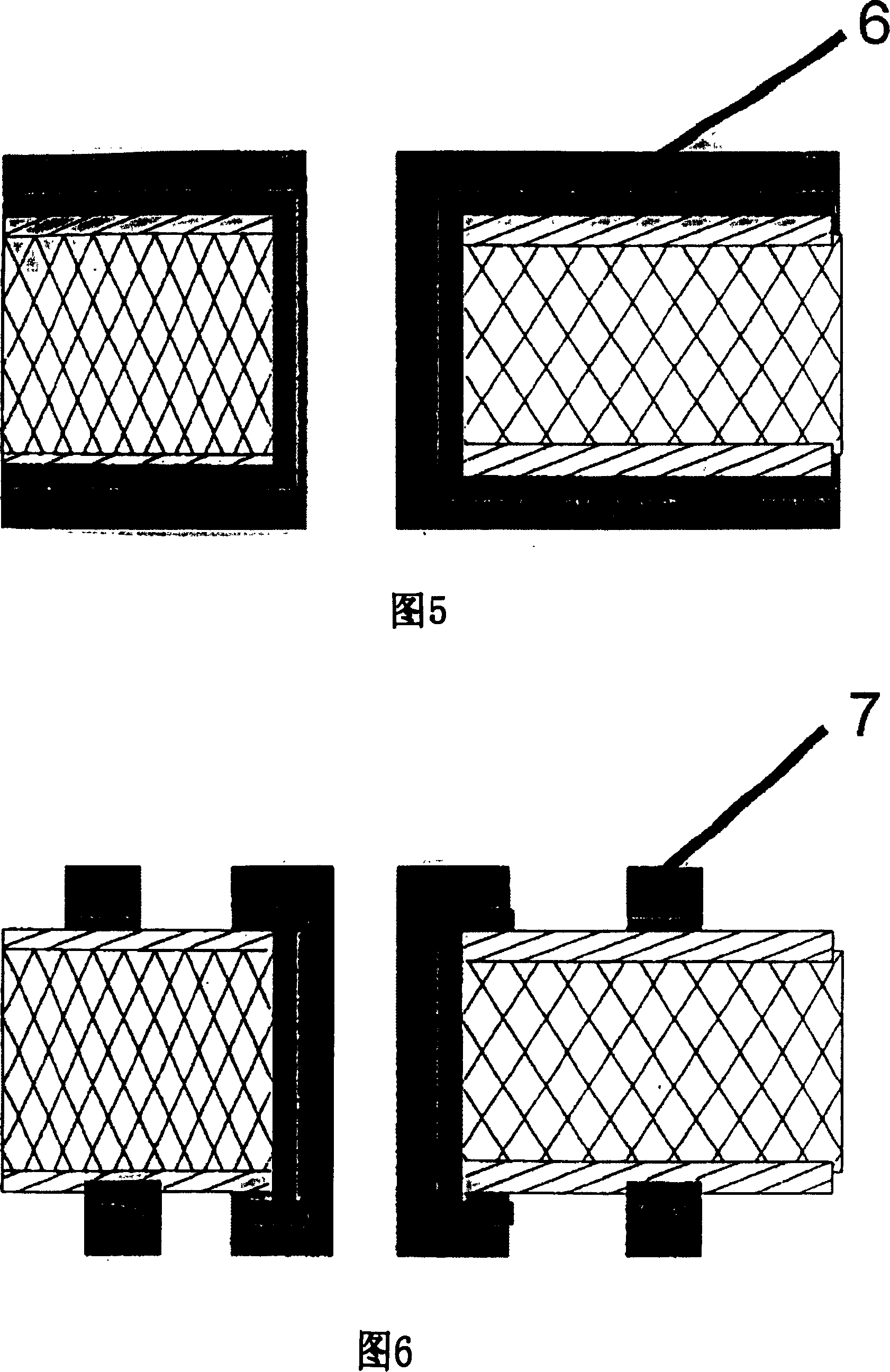

[0025] [017]. The present inventors have made painstaking researches to overcome the above-mentioned problems of the conventional technology, and found that using a polyimide containing a specific block copolymer and a specific horsepower formed on one surface of the copper foil Copper-clad laminates with excellent adhesive strength and heat resistance can be obtained by using a resin-composited copper foil with a resin layer of an imide compound. Based on the above findings, the present inventors have accomplished the present invention. That is, the present invention provides a resin composite copper foil comprising a copper foil and a resin layer containing a block copolymer polyimide and a maleimide compound, the resin layer being formed on one surface of the copper foil. The block copolymer polyimide is preferably a block copolymer polyimide having a structural unit represented by formula (1) and a structural unit represented by formula (2). The thickness of the resin lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com