Non polarity A side nitride film growing on the silicon(102) substrate and its making method and use

A non-polar, nitride technology, applied in the field of non-polar A-side nitride thin film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

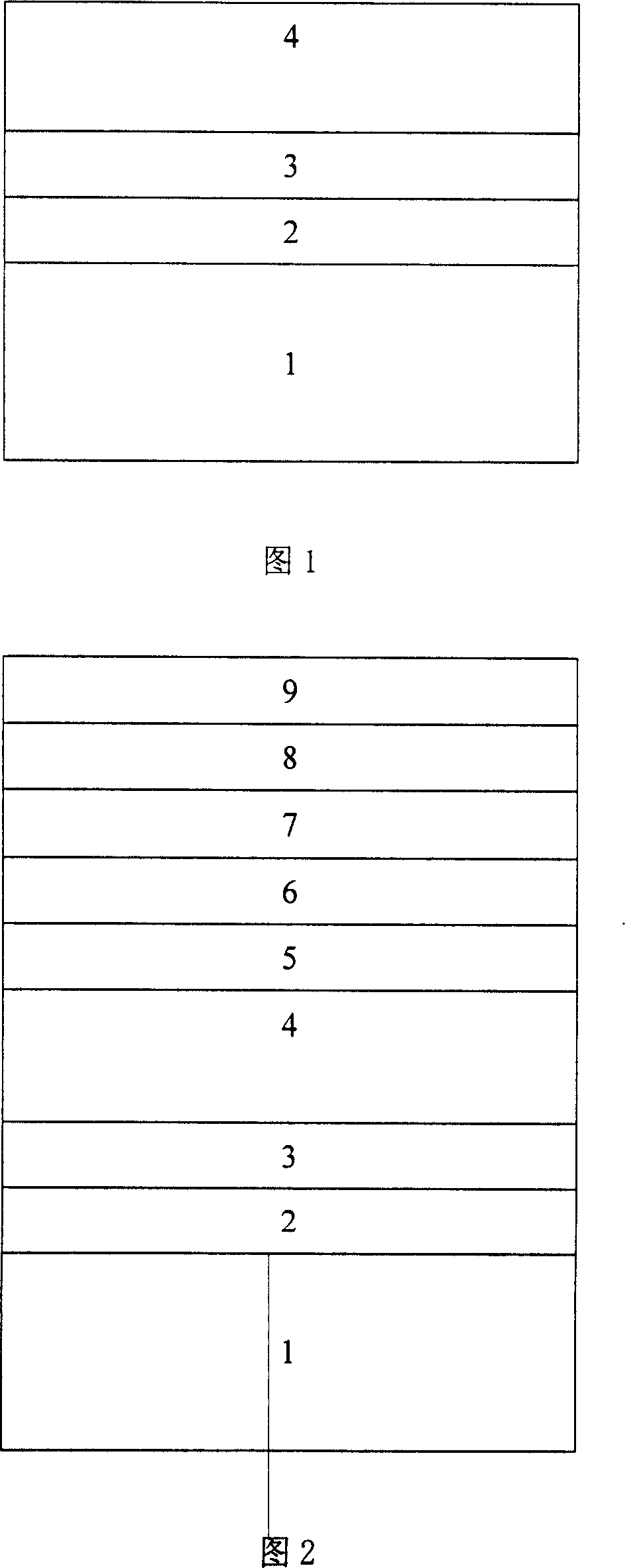

[0059] Embodiment 1, preparation of the non-polar A-side nitride thin film grown on the silicon substrate

[0060] A substrate with an off-angle of 5 degrees from silicon (102) to (010) is used, the thickness of the silicon wafer is 300 microns, the silicon wafer is N-type doped, and has low resistivity. After the silicon wafer is treated with organic solvent and hydrofluoric acid, it is sent into the MOCVD reaction chamber. The temperature of the reaction chamber is raised to 1100° C., the atmosphere of the reaction chamber is hydrogen, and the surface of the cleaned silicon substrate is annealed for desorption treatment to remove the oxide layer on the surface of the substrate. The temperature of the reaction chamber was lowered to 450°C, hydrogen was used as the carrier gas, and trimethylaluminum was passed through, and an Al metal layer with a thickness of 10 angstroms was deposited and grown on the surface of the silicon substrate through the pyrolysis reaction of trimeth...

Embodiment 2

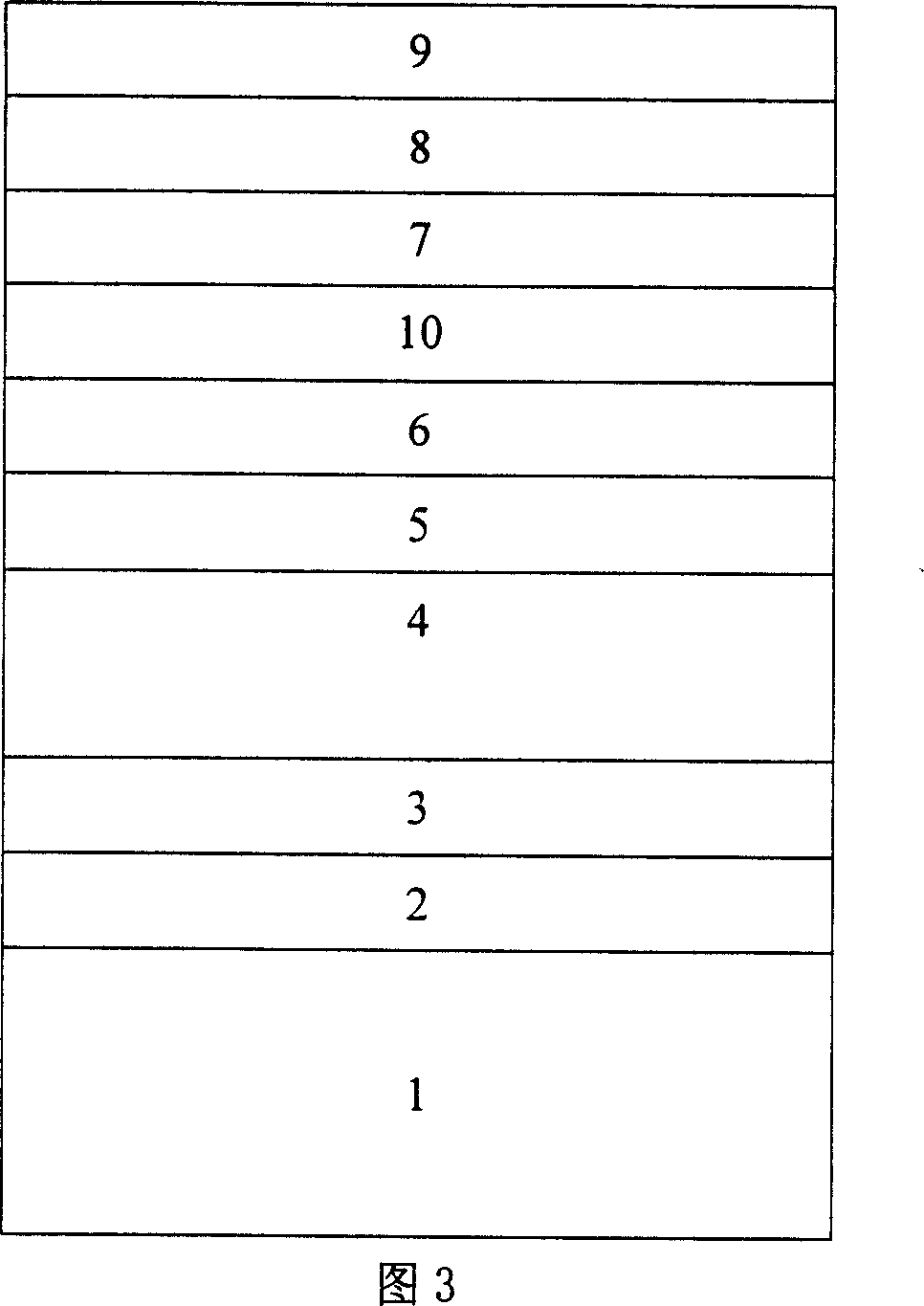

[0061] Embodiment 2, preparation of the non-polar A-side nitride thin film grown on the silicon substrate

[0062] Using a pattern substrate with an off-angle of 12 degrees from silicon (102) to (010), the pattern on the surface of the silicon wafer is a one-dimensional grating pattern with a width of 6 microns, a height of 2 microns, and a pitch of 6 microns, prepared by dry etching , the thickness of the silicon wafer is 300 microns, the silicon wafer is N-type doped, and has low resistivity. After the silicon wafer is treated with organic solvent and hydrofluoric acid, it is sent into the MOCVD reaction chamber. The temperature of the reaction chamber is raised to 600° C., the atmosphere of the reaction chamber is hydrogen, and the surface of the cleaned silicon substrate is annealed for desorption treatment to remove the oxide layer on the surface of the substrate. The temperature of the reaction chamber is lowered to 400°C, hydrogen is used as the carrier gas, and trimet...

Embodiment 3

[0063] Embodiment 3, preparation of the non-polar A-side nitride thin film grown on the silicon substrate

[0064]A silicon (102) substrate is used, the thickness of the silicon wafer is 300 microns, the silicon wafer is N-type doped, and has low resistivity. After the silicon wafer is treated with organic solvent and hydrofluoric acid, it is sent into the MOCVD reaction chamber. The temperature of the reaction chamber is raised to 600° C., the atmosphere of the reaction chamber is hydrogen, and the surface of the cleaned silicon substrate is annealed for desorption treatment to remove the oxide layer on the surface of the substrate. The temperature of the reaction chamber is lowered to 400°C, and the initial growth layer of InGaAlN is directly grown. With hydrogen as the carrier gas, trimethylaluminum and ammonia gas are passed through, and through the reaction of the two, the growth thickness of 100 angstroms AlN layer; the reaction chamber is heated to 600°C, and the AlN l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com