Silicon dioxide- aqueous polyurethane nano composite electrorheological fluid preparation method

A nano-composite, water-based polyurethane technology, used in lubricating compositions, petroleum industry, base materials, etc., to achieve the effects of not easy to settle, low leakage current density, and avoiding mutual entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

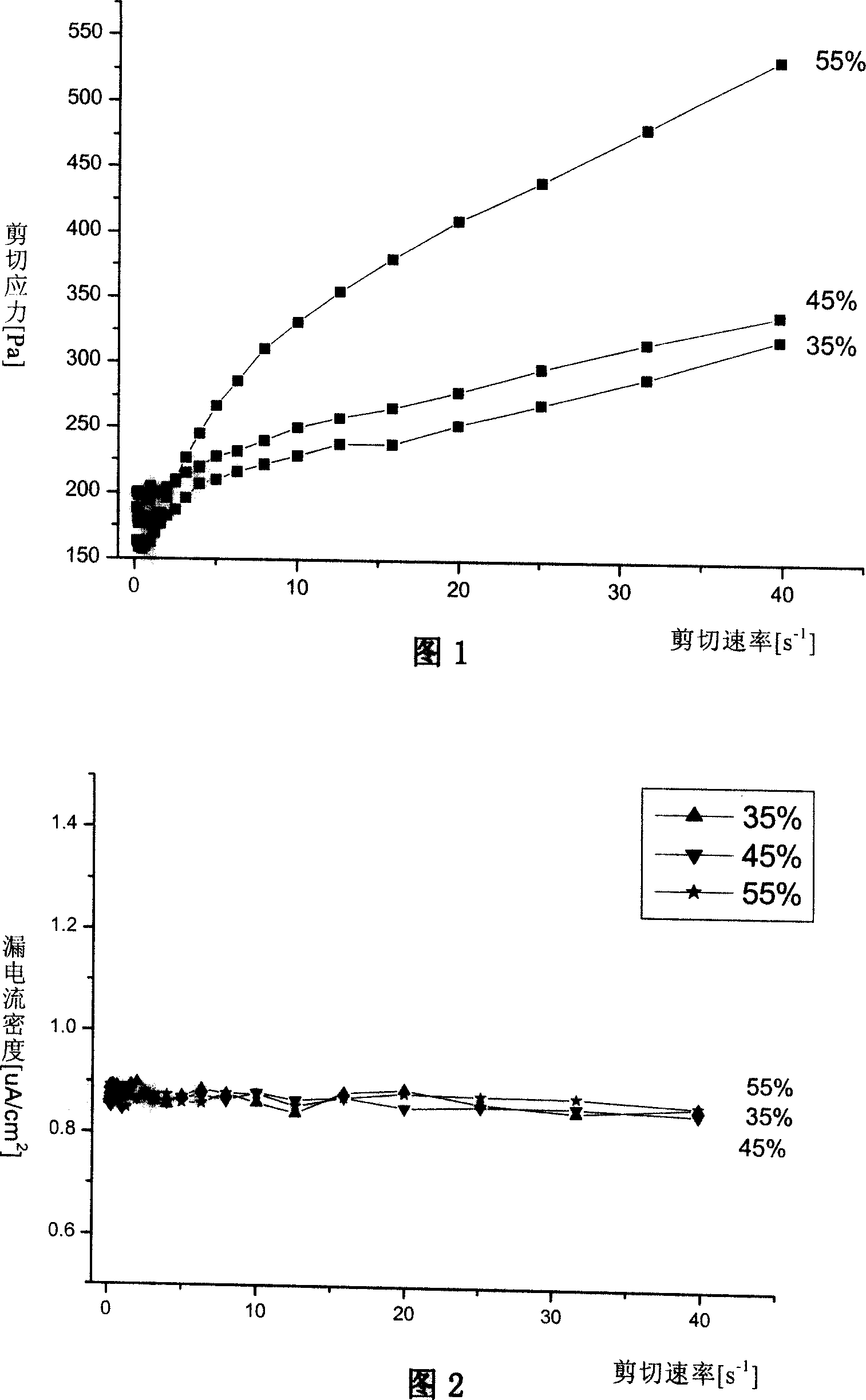

Embodiment 1

[0015] [Example 1] The content of ethyl orthosilicate is 35% (calculation formula is: percentage content of ethyl orthosilicate = ethyl orthosilicate mass / PU mass × 100%, the same below)

[0016] (1) Preparation of anionic polyurethane prepolymer:

[0017] In a three-necked flask equipped with a condensing device and an electric stirrer, the molar ratio is n NCO / n OH =1.5:1 Add polyester polyol, 4,4'-diphenylmethane diisocyanate (MDI) or hexamethylene diisocyanate (HDI), and 5-10ml of solvent ethyl acetate; heat up to 70 ~80℃, constant temperature reaction for 1.8~2 hours; at 75℃, the molar ratio is n COOH / n OH =3:1 Add chain extender dimethylolpropionic acid (DMPA), react for 0.8-1 hour; cool down to 45-50°C, add about 2.4 grams of isopropanol to block, and keep reacting for half an hour.

[0018] (2) Preparation of silica-waterborne polyurethane nanocomposite dispersion:

[0019] Take 41.42 grams of prepolymer and raise the temperature to 60°C, add 14.50 grams of te...

Embodiment 2

[0022] [Example 2] Tetraethyl orthosilicate content is 45%

[0023] (1) Preparation of anionic polyurethane prepolymer: same as Example 1.

[0024] (2) Preparation of silica-waterborne polyurethane nanocomposite dispersion:

[0025] Take 41.42 grams of prepolymer and raise the temperature to 60°C, add 18.64 grams of tetraethyl orthosilicate to react for half an hour, cool down to 40°C, add a certain amount of neutralizing agent triethylamine and react with carboxyl group for 15 minutes to form a salt. 147.21 ml of water were added and the solvent was distilled off. The silicon dioxide-anionic polyurethane aqueous dispersion with a solid content of 30% can be obtained.

[0026] (3) Electrorheological fluid for preparing silica-waterborne polyurethane nanocomposite:

[0027] Get the prepared silicon dioxide-anionic polyurethane aqueous dispersion and put it in a refrigerator to freeze into ice, and then put it on a freeze drier to dry for 24 hours. Grinding the dried compoun...

Embodiment 3

[0028] [Example 3] Tetraethyl orthosilicate content is 55%

[0029] (1) Preparation of anionic polyurethane prepolymer: same as Example 1.

[0030] (2) Preparation of silica-waterborne polyurethane nanocomposite dispersion:

[0031] Take 41.42 grams of prepolymer and raise the temperature to 60°C, add 22.78 grams of tetraethyl orthosilicate to react for half an hour, cool down to 40°C, add a certain amount of neutralizing agent triethylamine and react with carboxyl group for 15 minutes to form a salt. 156.87 ml of water were added and the solvent was distilled off. The silicon dioxide-anionic polyurethane aqueous dispersion with a solid content of 30% can be obtained.

[0032] (3) Electrorheological fluid for preparing silica-waterborne polyurethane nanocomposite:

[0033] Get the prepared silicon dioxide-anionic polyurethane aqueous dispersion and put it in a refrigerator to freeze into ice, and then put it on a freeze drier to dry for 24 hours. Grinding the dried compoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com