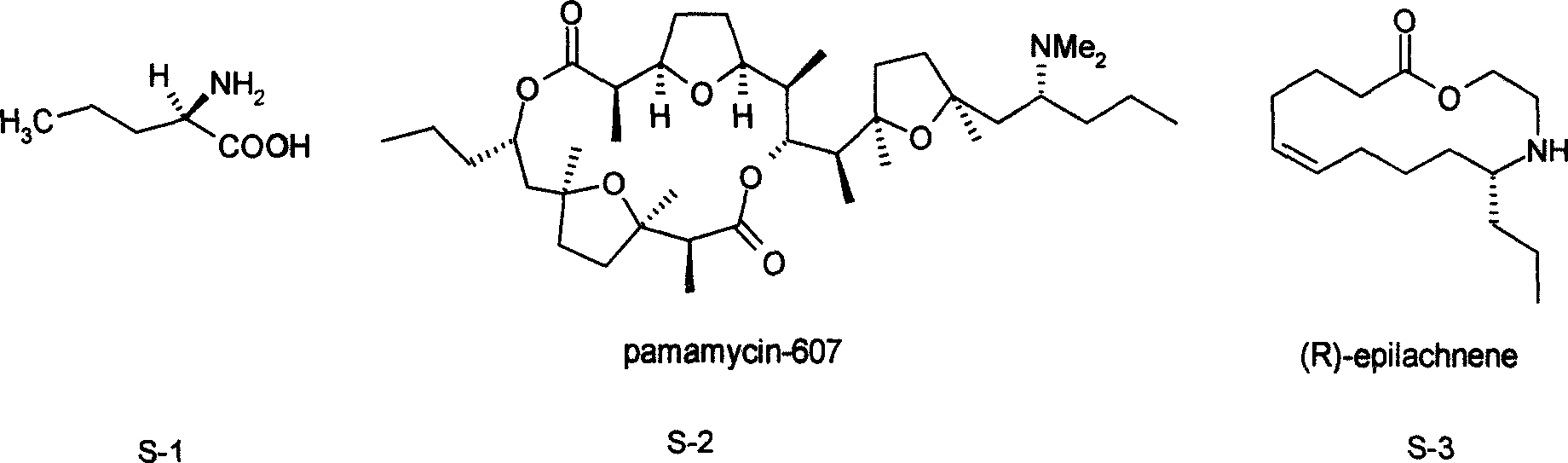

Method for synthesizing D-norvaline using n-pentanoic acid

A technology of norvaline and nvaleric acid, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of high cost, complicated starting materials, complex synthesis process, etc., and achieve low cost, The effect of short production cycle and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

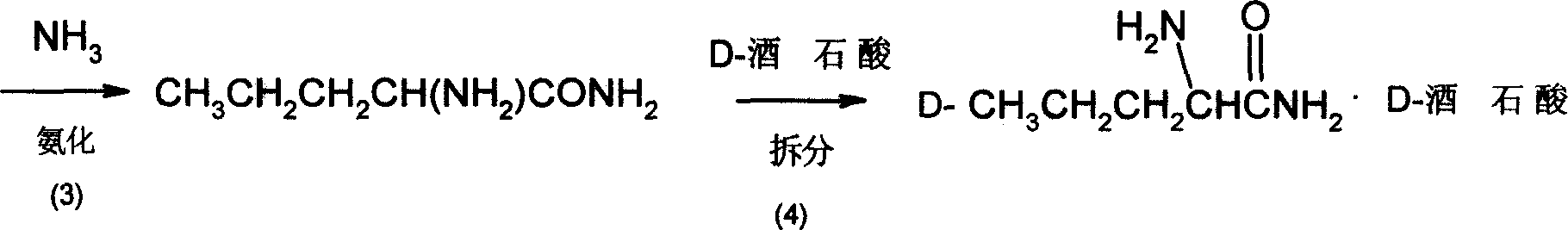

Method used

Image

Examples

Embodiment 1

[0022] The synthetic method of D-norvaline, take n-valeric acid as main starting raw material, make through following steps successively:

[0023] (1) Acyl chloride, i.e. the preparation of n-pentanoyl chloride:

[0024] In the flask equipped with stirring, reflux condenser, dropping funnel, calcium chloride drying tube and thermometer, add n-valeric acid (36.7g, 0.36mol) and thionyl chloride (123.9g, 1.04mol) successively, oil Bath heating, reflux at 78 ° C for 4 hours, until no hydrogen chloride gas is released.

[0025] (2) bromination, preparation of α-bromovaleryl chloride:

[0026] Keep the liquid obtained in the previous step slightly boiling, and the reaction temperature is 80°C. Liquid bromine (60.5 g, 0.38 mol) dried with an equal volume of concentrated sulfuric acid is added dropwise to the flask, and the dropping process is completed within 6 hours. After the dropwise addition was completed, heating and stirring were stopped, and the mixture was allowed to stand ...

Embodiment 2

[0037] The synthetic method of D-norvaline, take n-valeric acid as main starting raw material, make through following steps successively:

[0038] (1) Acyl chloride, i.e. the preparation of n-pentanoyl chloride:

[0039] In the flask equipped with stirring, reflux condenser, dropping funnel, calcium chloride drying tube and thermometer, add n-valeric acid (36.7g, 0.36mol) and thionyl chloride (85.8g, 0.72mol) successively, oil Bath heating, 60 ℃ reaction 8h, until no hydrogen chloride gas is released.

[0040] (2) bromination, preparation of α-bromovaleryl chloride:

[0041]Keeping the temperature of the liquid obtained in the previous step at 50°C, liquid bromine (115.2 g, o.72 mol) dried with an equal volume of concentrated sulfuric acid was added dropwise to the flask, and the dropping process was completed within 8 hours. After the dropwise addition was completed, heating and stirring were stopped, and the mixture was allowed to stand overnight. The next day, rectificat...

Embodiment 3

[0052] The synthetic method of D-norvaline, take n-valeric acid as main starting raw material, make through following steps successively:

[0053] (1) Acyl chloride, i.e. the preparation of n-pentanoyl chloride:

[0054] In the flask equipped with stirring, reflux condenser, dropping funnel, calcium chloride drying tube and thermometer, add n-valeric acid (36.7g, 0.36mol) and thionyl chloride (214.4g, 1.80mol) successively, water bath Reaction at 70°C for 6h.

[0055] (2) bromination, preparation of α-bromovaleryl chloride:

[0056] Keeping the temperature of the liquid obtained in the previous step at 70°C, liquid bromine (86.4 g, 0.54 mol) dried with an equal volume of concentrated sulfuric acid was added dropwise to the flask, and the dropping process was completed within 10 h. After the dropwise addition was completed, the stirring was stopped and left to stand overnight. The next day, rectification under reduced pressure collected 56 g of 88-90°C / 9mmHg fraction, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com