Process for preparing MnZn soft magnetic ferrite particles

A technology of manganese-zinc soft magnets and granular materials, applied in the direction of inorganic material magnetism, can solve the problems of many supporting equipment, serious pollution, deviation of volatile components, etc., and achieve the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

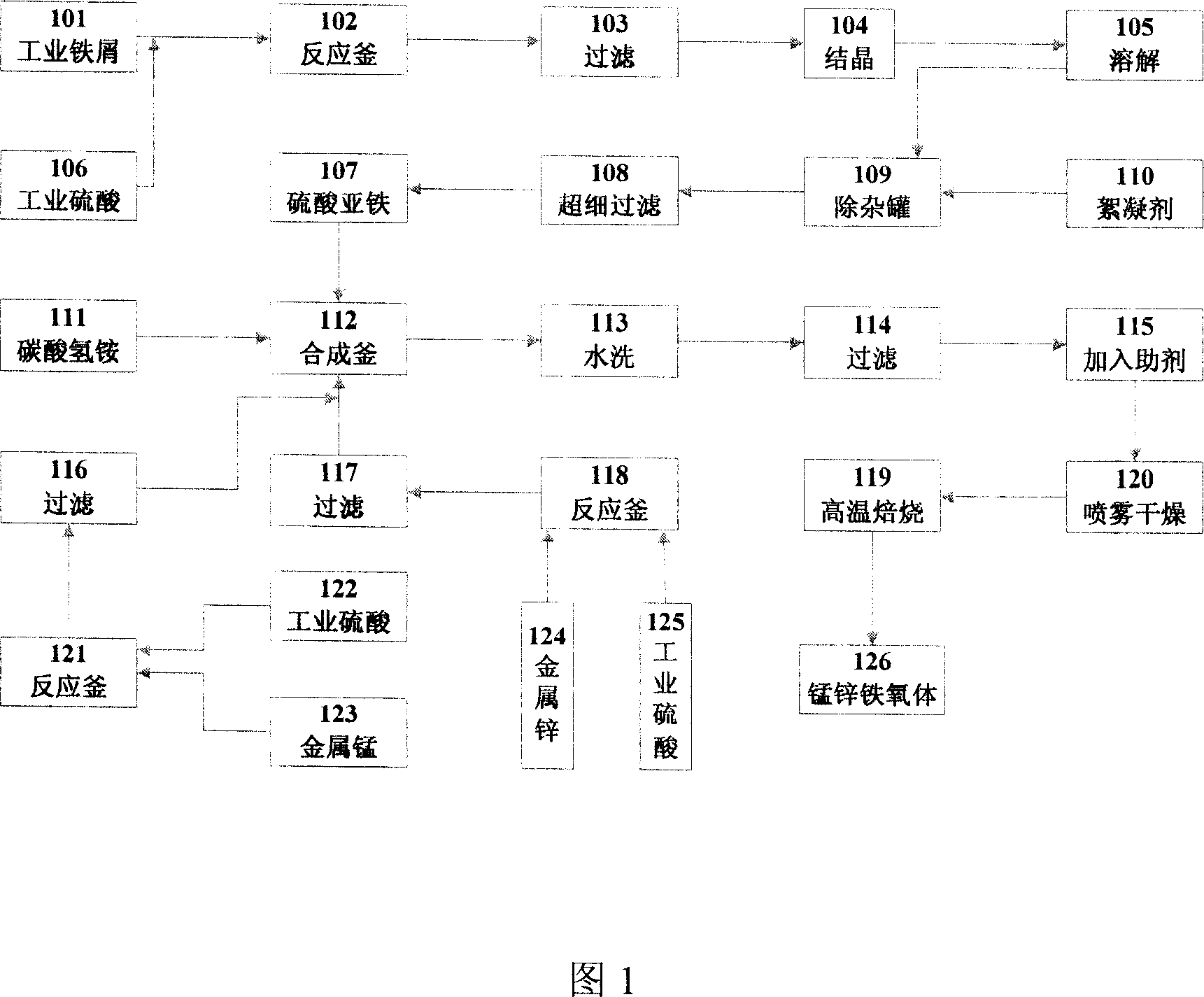

Image

Examples

Embodiment 2

[0029]Embodiment 2: the 7.63T ferrous sulfate working solution after impurity removal, the manganese sulfate working solution of 1.627T, the zinc sulfate working solution of 0.921T are transported together in the screw mixer and mixed, and then mixed with 3.08T ammonium bicarbonate Add 15.899T pure water into the synthesis reaction kettle, carry out the synthesis reaction at 55°C and pH value of 7.5 for 3 hours, and produce iron carbonate, manganese carbonate and zinc carbonate precipitates; then use a centrifugal separator for primary separation , washed with water, and then the sediment was sent to a sand mill, and 200ppm of Bi was added 2 o 3 , 200 ppm of MoO 3 Coarsely grind with 150ppm CaO, then send the precipitate to the centrifugal spray granulation tower for spray granulation, and then send the powder to the rotary kiln for roasting at a temperature of 900°C to obtain manganese-zinc soft magnets Oxygen pellets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com