High strength, high electroconductive copper alloy material and preparation tech. thereof

A technology for preparation process and alloy material, applied in the field of copper alloy material and its preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

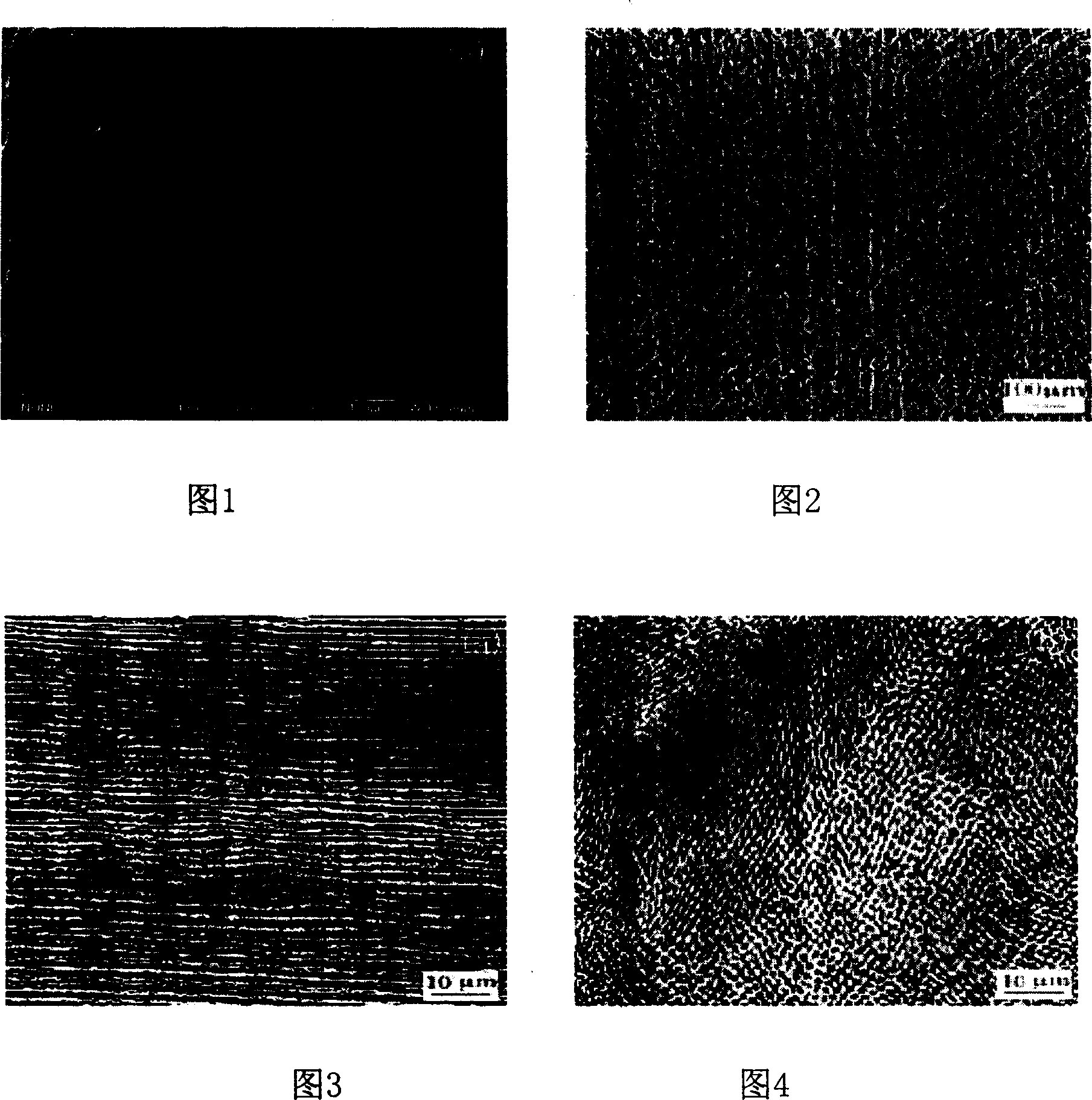

Image

Examples

Embodiment 1

[0030] The continuous directionally solidified Be-Ag-Cu alloy rods are prepared on the horizontal drawing hot-type continuous casting equipment. The specific preparation process is as follows:

[0031] ① Melt high-purity copper with a purity of 99%, then raise the temperature to 1120°C, and refine for 25 minutes. The entire melting process is protected by 99.9% pure argon;

[0032] ②According to the composition requirements and theoretical burning loss, add a certain amount of Be-Cu master alloy and Ag-Cu master alloy, so that the content of Be is 0.06wt%, Ag0.08wt%, and the balance of Cu; the master alloy is baked before adding Dry treatment, the drying temperature is 200°C, the drying time is 2 hours, and the oxide layer on the surface is removed; after adding, the argon gas is used to fully boil the copper alloy melt to ensure the uniform structure of the alloy;

[0033] ③ The specific process parameters for drawing Be-Ag-Cu alloy rods by means of continuous directional sol...

Embodiment 2

[0036] ① Melt high-purity copper with a purity of 99.9%, and then heat up to 1160°C to 1200°C for 20 minutes of refining. The entire melting process is protected by 99.9% high-purity argon;

[0037] ②According to the composition requirements and theoretical burning loss, add a certain amount of Be-Cu master alloy and Ag-Cu master alloy, so that the content of Be is 0.09wt%, Ag0.12wt%, and the balance of Cu. Dry and treat the intermediate alloy before adding, the treatment temperature is 250°C, the drying time is 1.5 hours, and remove the oxide layer on the surface; after adding, the copper alloy melt is fully boiled with argon gas to ensure the uniform structure of the alloy;

[0038] ③ The specific process parameters for drawing Be-Ag-Cu alloy rods by means of continuous directional solidification are: copper alloy melt temperature 1190°C, hot-type continuous casting equipment main furnace temperature 1170°C, horizontal lead pipe temperature 1130°C, mold mouth The temperature...

Embodiment 3

[0041] ① Melt high-purity copper with a purity of 99.9%, and then heat up to 1200°C for 15 minutes to refine. The entire melting process is protected by 99.9% high-purity argon;

[0042] ②According to the composition requirements and theoretical burning loss, add a certain amount of Be-Cu master alloy and Ag-Cu master alloy so that the content of Be is 0.12wt%, Ag0.15wt%, and the balance of Cu. Before adding, the master alloy is dried at a temperature of 300°C and the drying time is 1 hour, and the oxide layer on the surface is removed; after the addition, the copper alloy melt is fully boiled with argon gas to ensure a uniform alloy structure;

[0043] ③ The specific process parameters for drawing Be-Ag-Cu alloy rods by means of continuous directional solidification are: copper alloy melt temperature 1220°C, hot-type continuous casting equipment main furnace temperature 1200°C, horizontal lead pipe temperature 1160°C, mold mouth The temperature is 1160°C, the cooling water vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com