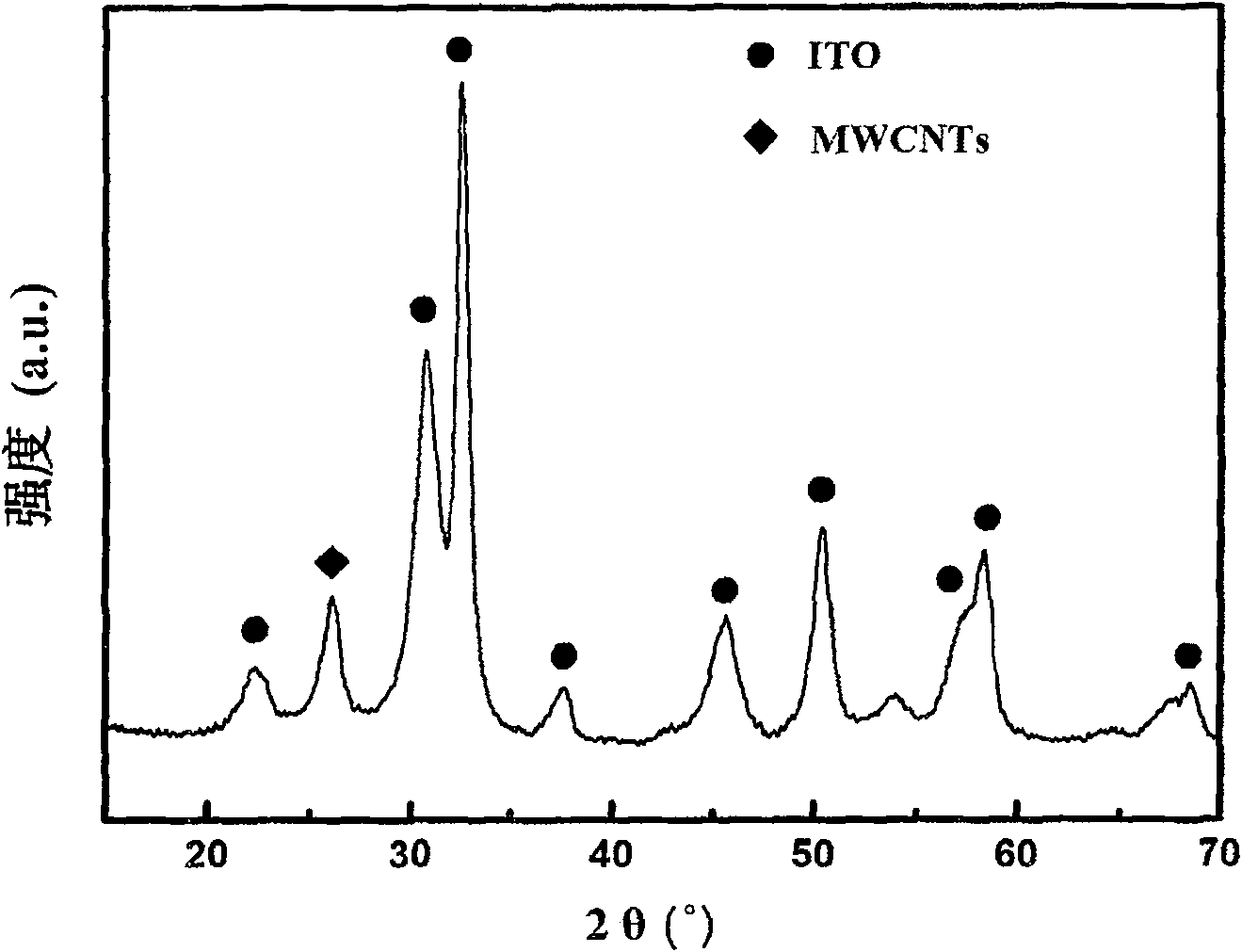

Method for preparing composite material of nano-indium stannum oxide/multi-wall carbon nano-tube

A technology of multi-walled carbon nanotubes and composite materials, applied in the field of preparation of composite materials, achieving the effects of simple production equipment requirements, controllable reaction conditions, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

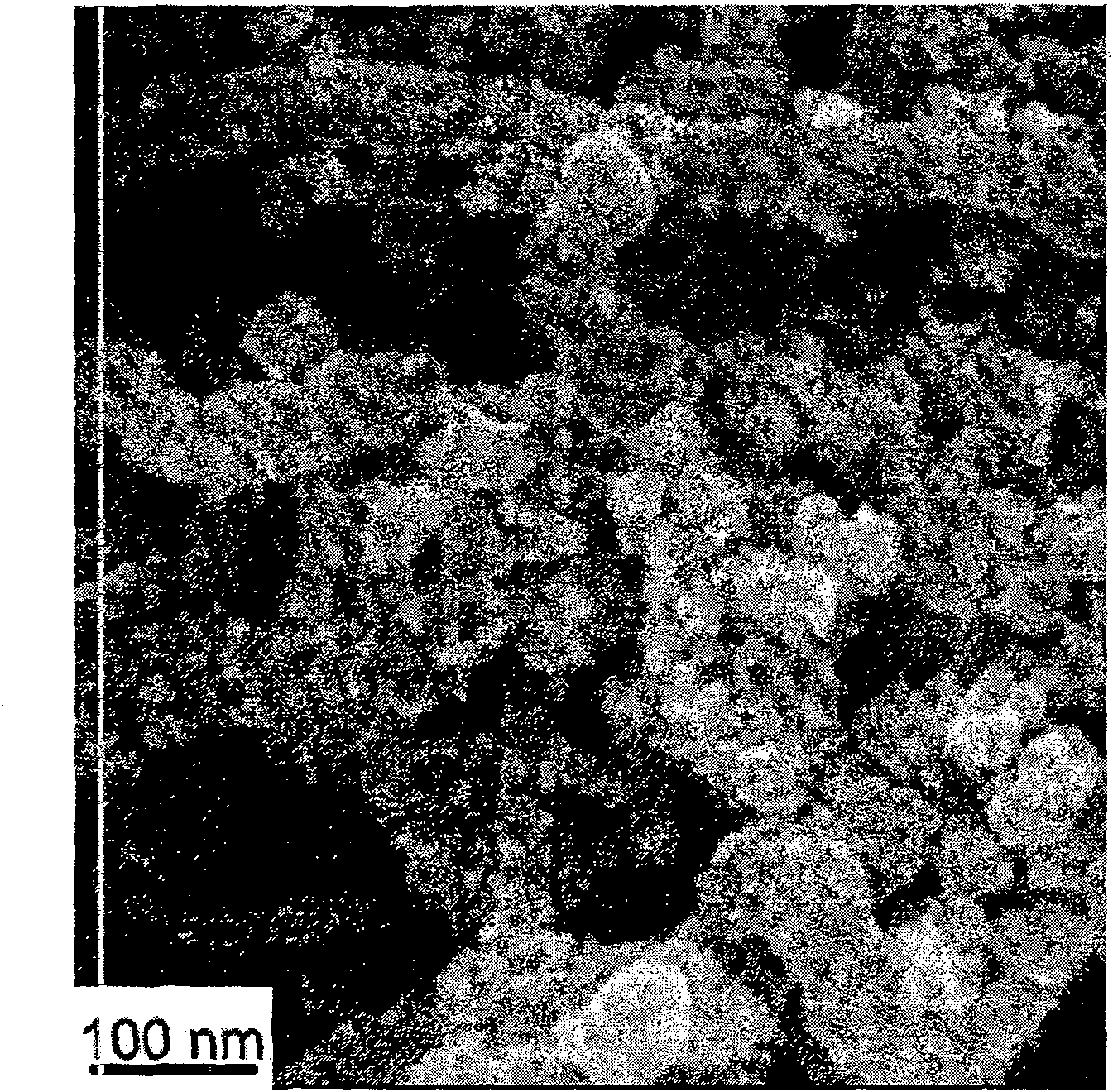

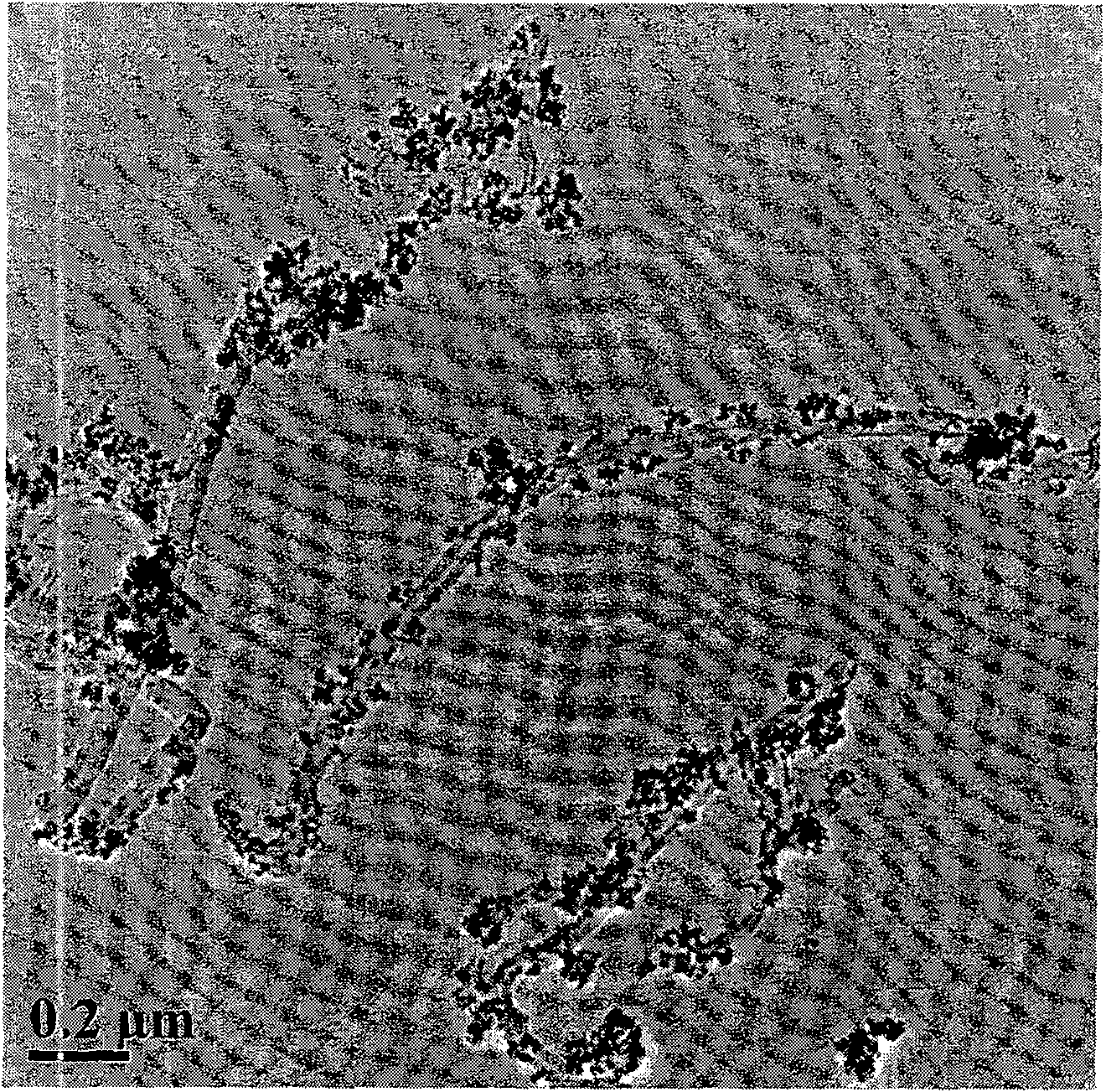

[0024] Weigh 0.15g MWCNTs into a three-necked flask, then add 30g (45wt%) concentrated nitric acid, ultrasonically disperse for 30min, then raise the temperature to 100°C, and acidify for 30h. After the reaction, the carbon tube suspension was filtered, washed and dried to obtain MWCNTs after acidification treatment. Then weigh 0.1435g SnCl 4 ·5H 2 O, 1.1732g InCl 3 4H 2 O, put it into a three-necked flask, add 80mL of deionized water and the above-mentioned acidified MWCNTs, stir well, heat up to 60°C, then add ammonia water dropwise to the three-necked flask to pH=8.5, and mechanically stir at 150 rpm for a total of Precipitation reaction 4h. After the reaction, the product is suction filtered, washed and dried to obtain carbon nanotubes assembled with indium tin hydroxide. The above precursor products were put into a crucible and placed in a muffle furnace, and the temperature was raised from room temperature to 330 °C at a heating rate of 3 °C / min, kept for 2 h, and t...

Embodiment 2

[0026] Weigh 0.1g MWCNTs into a three-necked flask, then add 30g (60wt%) concentrated nitric acid, ultrasonically disperse for 30min, then raise the temperature to 120°C, and acidify for 18h. After the reaction, the carbon tube suspension was filtered, washed and dried to obtain acidified MWCNTs. Weigh 0.0711g SnCl4 ·5H 2 O, 0.5866g InCl 3 4H 2 O, put it into a three-necked flask, add 70mL of deionized water and the above-mentioned acidified MWCNTs, stir well, heat up to 65°C, then add ammonia water dropwise to the three-necked flask to pH=9.0, and mechanically stir at 120 rpm for a total of Precipitation reaction 4h. After the reaction, the product is suction filtered, washed and dried to obtain carbon nanotubes assembled with indium tin hydroxide. The above precursor products were put into a crucible and placed in a muffle furnace, and the temperature was raised from room temperature to 330 °C at a heating rate of 2 °C / min, kept for 3 h, and then cooled naturally to obta...

Embodiment 3

[0028] Weigh 0.1g MWCNTs into a three-necked flask, then add 20g (35wt%) concentrated nitric acid, ultrasonically disperse for 30min, then raise the temperature to 120°C, and acidify for 48h. After the reaction, the carbon tube suspension was filtered, washed and dried to obtain acidified MWCNTs. Weigh 0.1005g SnCl 4 ·5H 2 O, 0.8212g InCl 3 4H 2 O, put it into a three-necked flask, add 90 mL of deionized and acidified MWCNTs, stir well, raise the temperature to 65°C, then add ammonia water dropwise to the three-necked flask to pH = 8.5, mechanically stir at 120 rpm, and co-precipitate Reaction 5h. After the reaction, the product is suction filtered, washed and dried to obtain carbon nanotubes assembled with indium tin hydroxide. The above precursor products were put into a crucible and placed in a muffle furnace, and the temperature was raised from room temperature to 340 °C at a heating rate of 3 °C / min, kept for 3 h, and then cooled naturally to obtain nano-ITO / MWCNTs c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com