Method for synthesizing N,N,N',N'-methylethylenediamine using pipe reactor

A technology of tetramethylethylenediamine and pipeline reactors, which is applied in chemical methods for liquid-liquid reactions, chemical instruments and methods, preparation of functional groups substituted by amino groups, etc., can solve the problems of harsh reaction conditions, high prices, and catalyst recovery costs. Problems and other issues, to achieve a good security effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

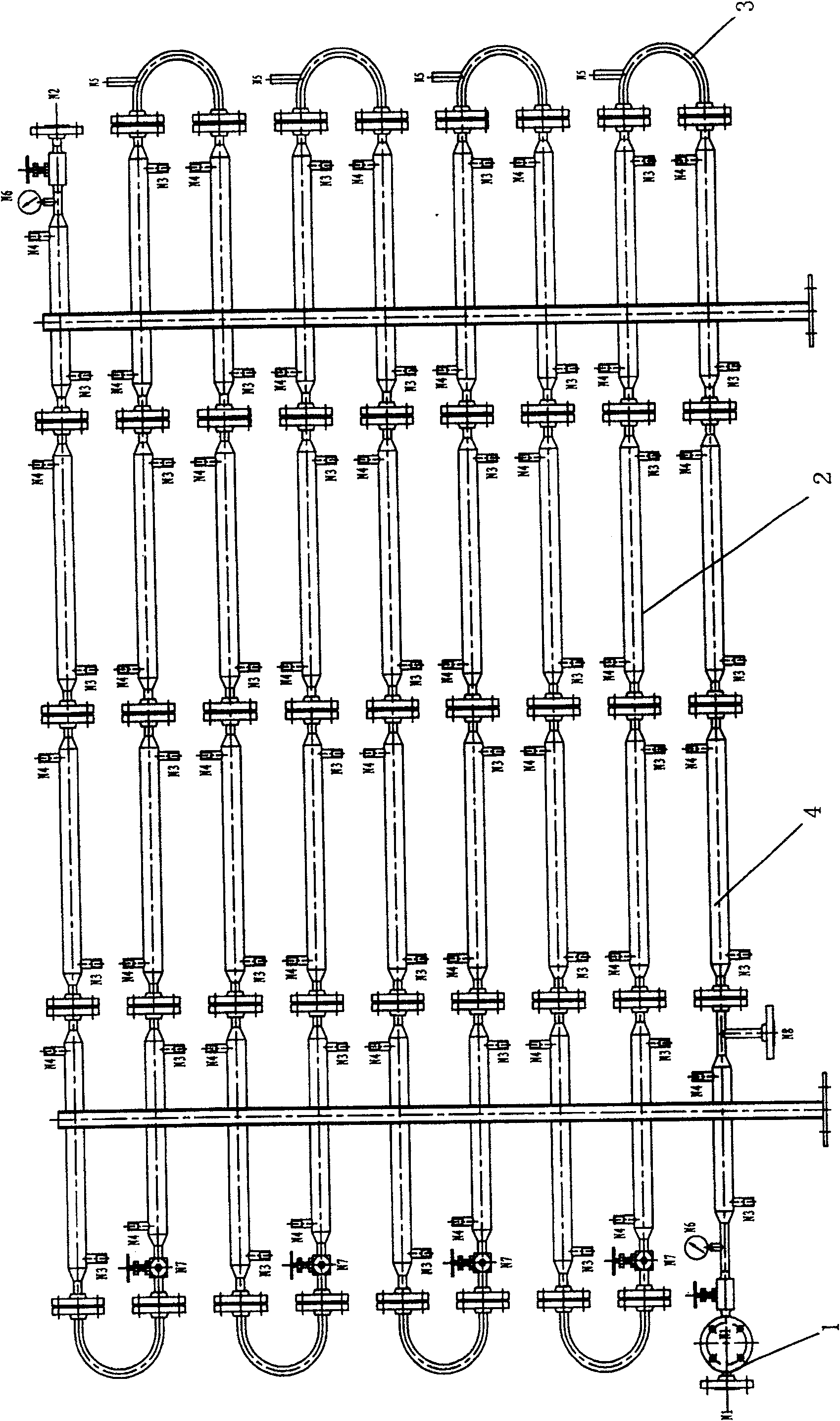

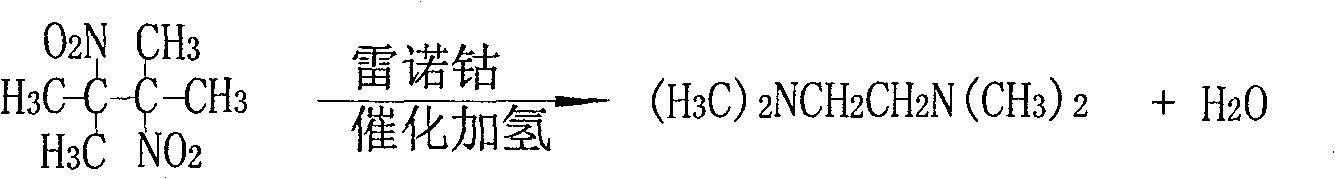

[0027] Embodiment 1: a kind of N, N, N', the synthetic method of N'-tetramethylethylenediamine, reaction process is as follows:

[0028] Take 989.7g (1mol) of 1,2-dichloroethane, 410g of sodium hydroxide, 4508g (10mol) of dimethylamine, and 1950g of benzene. The reactor adopts a pipeline reactor, and the feed adopts a metering pump. Keep the temperature of the reactor jacket at 180°C, adjust the flow rate, divide the above raw materials into two groups and pour them into the pipeline reactor at the same time, the system pressure is 0.82Mpa, and the reaction residence time is 10 minutes. The synthetic solution was rectified, and the fraction at 119-121°C was extracted to obtain 1005 g of the product, with a yield of 86.50%.

Embodiment 2

[0029] Embodiment 2: a kind of N, N, N', the synthetic method of N'-tetramethylethylenediamine, reaction process is as follows:

[0030] Take 989.7g (1mol) of 1,2-dichloroethane, 410g of sodium hydroxide, 3606g (8mol) of dimethylamine, and 1800g of toluene. The reactor adopts a pipeline reactor, and the feed adopts a metering pump. Keep the reactor jacket temperature at 150°C, adjust the flow rate, divide the above raw materials into two groups and inject them into the pipeline reactor at the same time, the system pressure is 0.68Mpa, and the reaction residence time is 8 minutes. The synthetic solution was rectified, and the fraction at 119-121°C was extracted to obtain 1018g of the product, with a yield of 87.60%.

Embodiment 3

[0031] Embodiment 3: a kind of N, N, N', the synthetic method of N'-tetramethylethylenediamine, reaction process is as follows:

[0032]Take 989.7g (1mol) of 1,2-dichloroethane, 410g of sodium hydroxide, 2704g (6mol) of dimethylamine, and 1500g of methanol. The reactor adopts a pipeline reactor, and the feed adopts a metering pump. Keep the reactor jacket temperature at 120°C, adjust the flow rate, divide the above raw materials into two groups and pour them into the pipeline reactor at the same time, the system pressure is 0.46Mpa, and the reaction residence time is 12 minutes. The synthetic solution was rectified, and the fraction at 119-121°C was extracted to obtain 1048g of the product, with a yield of 90.10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com