Silicon based LCD micro- display and method for forming same

A technology of microdisplay and liquid crystal on silicon, applied in the field of semiconductor, can solve the problems of difficult monolithic structure and large influence of adjacent units, and achieve the effect of small interference effect and small mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

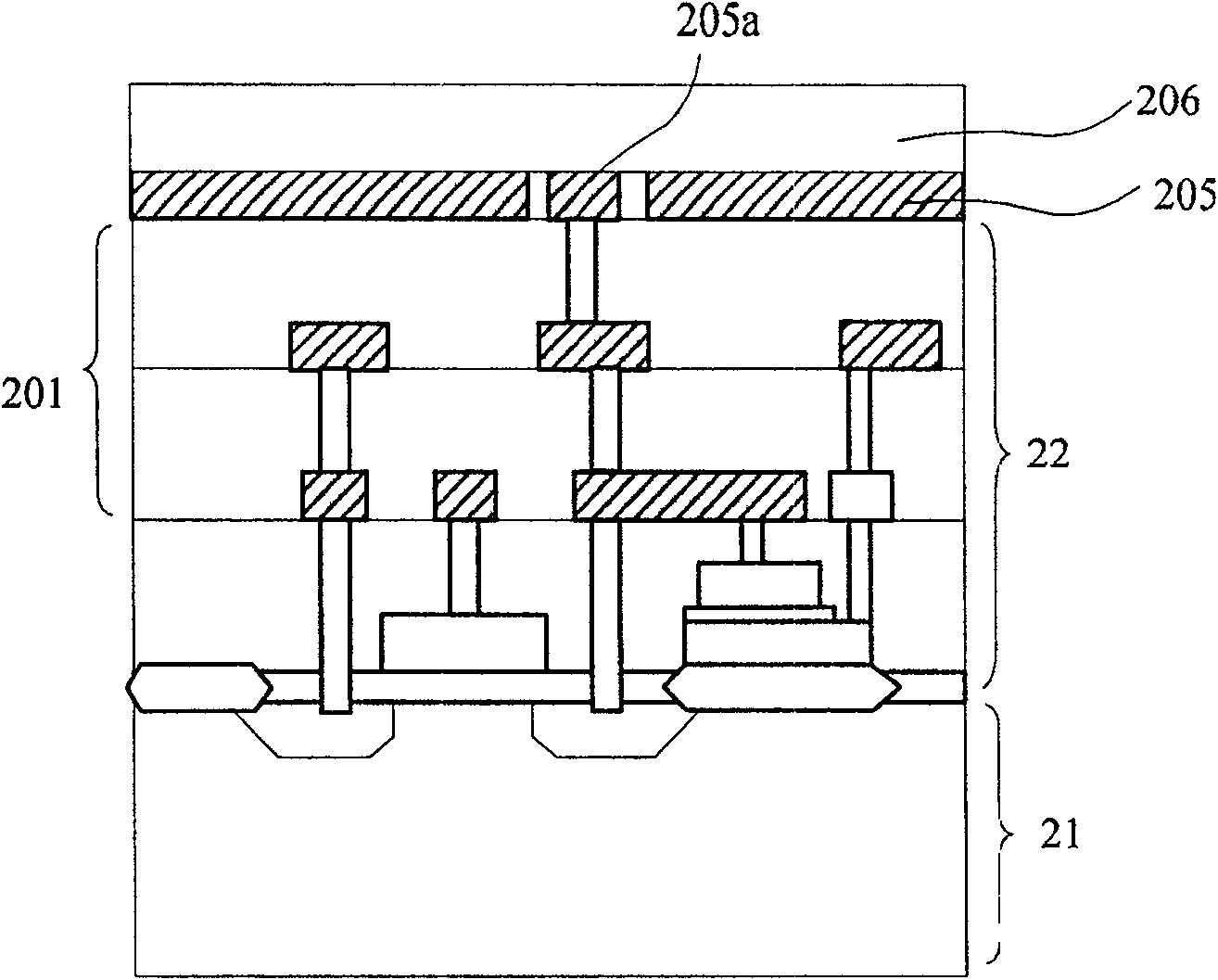

[0024] The essence of the present invention is to provide a silicon-based liquid crystal microdisplay and a method for forming the same. The microreflector of the silicon-based liquid crystal microdisplay is a honeycomb regular hexagon. The pixel switch circuit layer of the silicon-based liquid crystal microdisplay provided by the present invention The random memory composed of MOS transistors and capacitors can also be other forms of static random access memory circuits or pixel switch circuits composed of address selection diodes. The protection scope of the present invention should not be excessively limited here.

[0025] In the following, specific embodiments are described in detail according to the accompanying drawings to make the above-mentioned objectives and advantages of the present invention more clear:

[0026] First, a method for forming a silicon-based liquid crystal microdisplay unit is given. A pixel switch circuit layer and an intermetallic insulating layer are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com