Full-automatic assembly production chain of energy-saving lamp

An assembly line and fully automatic technology, applied in the manufacture of discharge tubes/lamps, machines with sequentially arranged working positions, electrical components, etc., can solve problems such as low production efficiency, weakened product market competitiveness, and increased production costs. Achieve the effect of improving production efficiency and product quality stability, improving product appearance and internal quality, reducing product scrap rate and rework rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing of description:

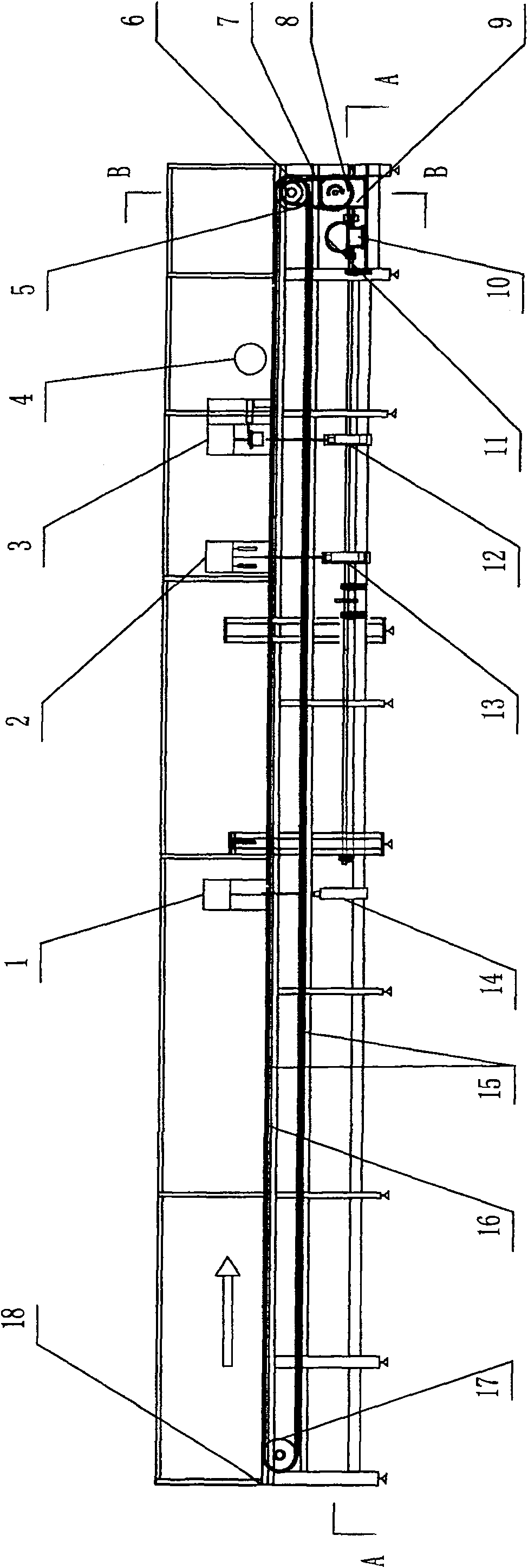

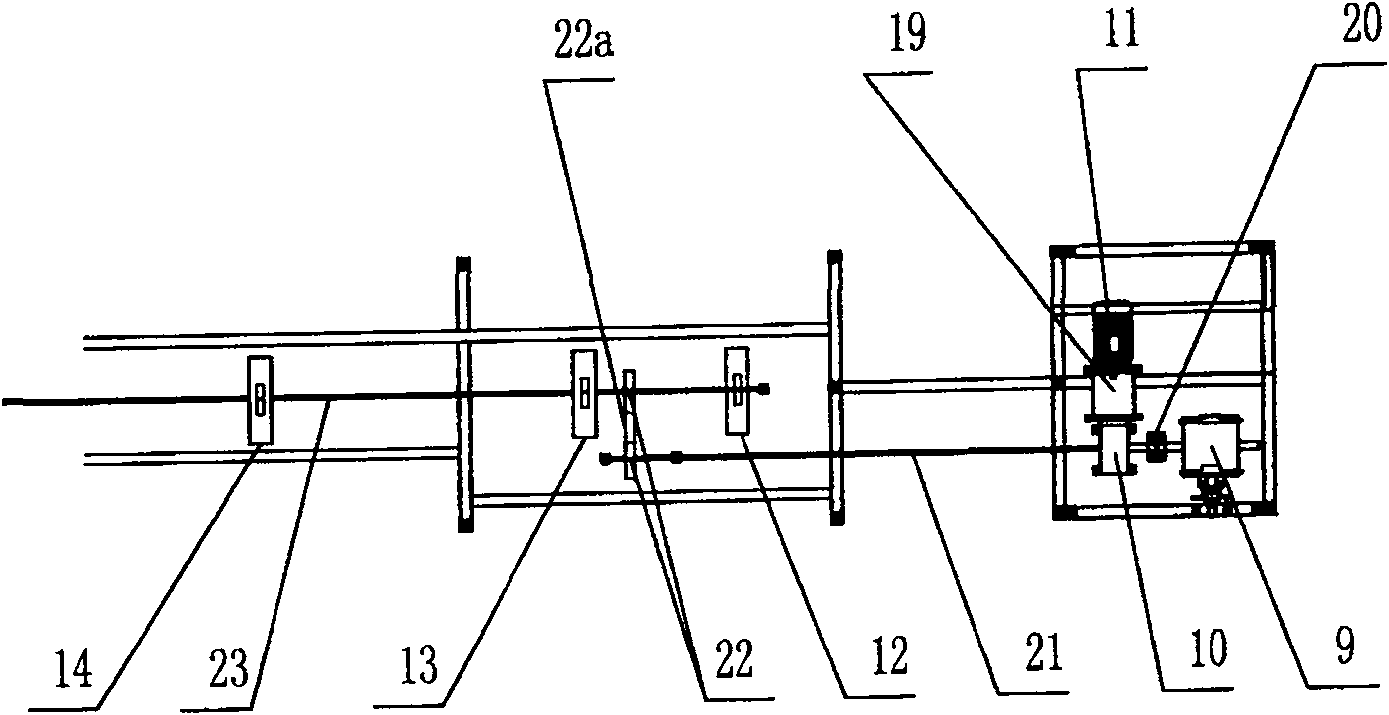

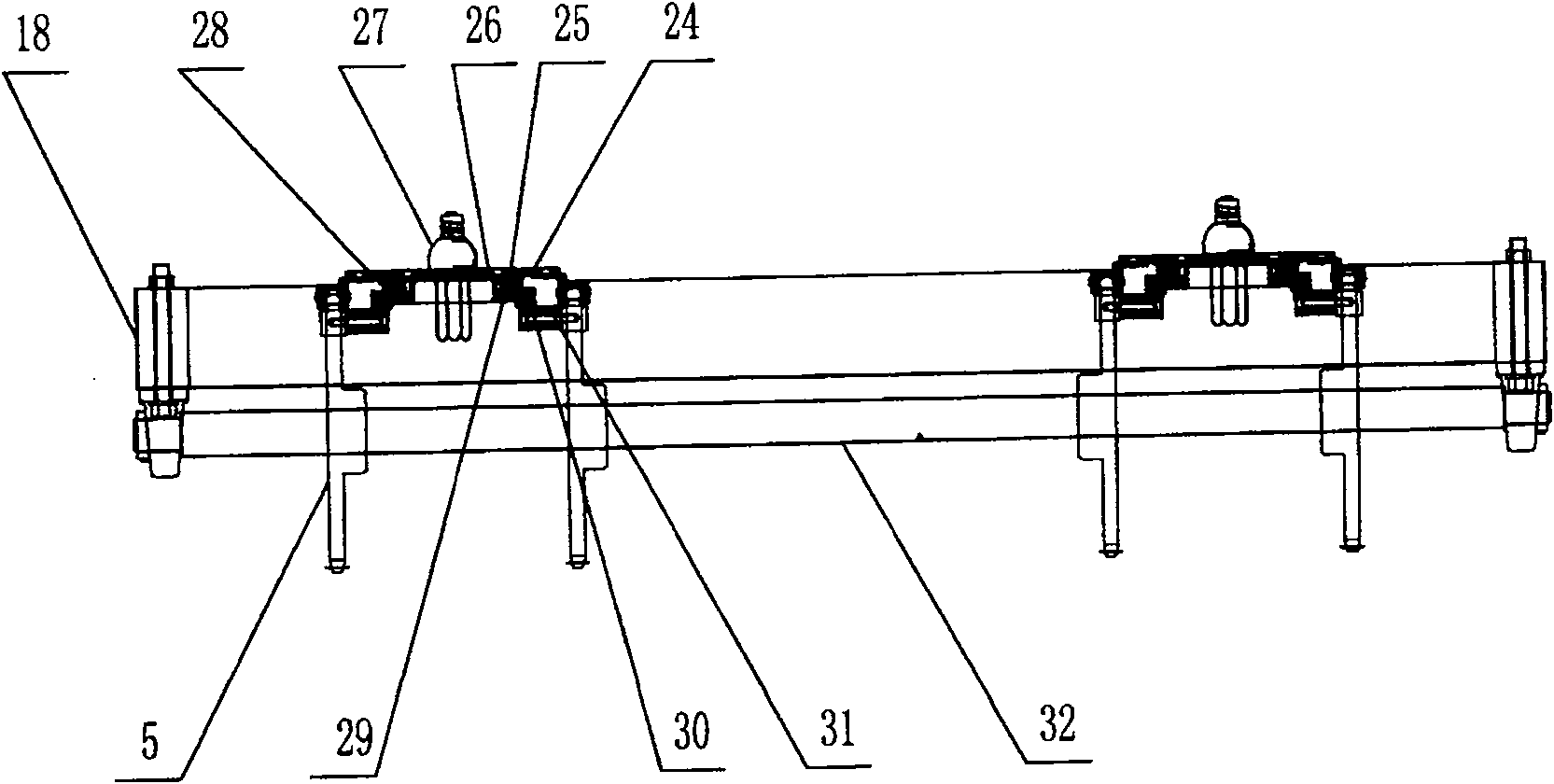

[0030] As shown in the figure, the frame 18 of the fully automatic assembly line for energy-saving lamps has an upper, middle and lower three-layer structure, which is formed by connecting industrial aluminum profiles, various square pipes, and square steel. The upper layer is mainly used for placing lighting equipment 35 and Hang various operating tools. The middle layer of the frame 18 cooperates to install the workpiece conveying device 28 driven by the transmission chain 15, and the position of the conveying chain 15 is matched with the guide rail 16. The workpiece conveying device 28 can be arranged in parallel with one or more. In this embodiment, the middle layer of the frame 18 is arranged in parallel. Two workpiece conveying devices 28. The workpiece conveying device 28 is composed of a transmission chain 15, an aluminum alloy panel 26, and an alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com