Animal protein regenerated fiber spunlaced non-woven fabric

A technology for regenerated fibers and non-woven fabrics, applied in the directions of non-woven fabrics, single-component protein rayon, fiber chemical characteristics, etc. Simple process, soft and smooth skin, excellent health care effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with example the present invention will be further described:

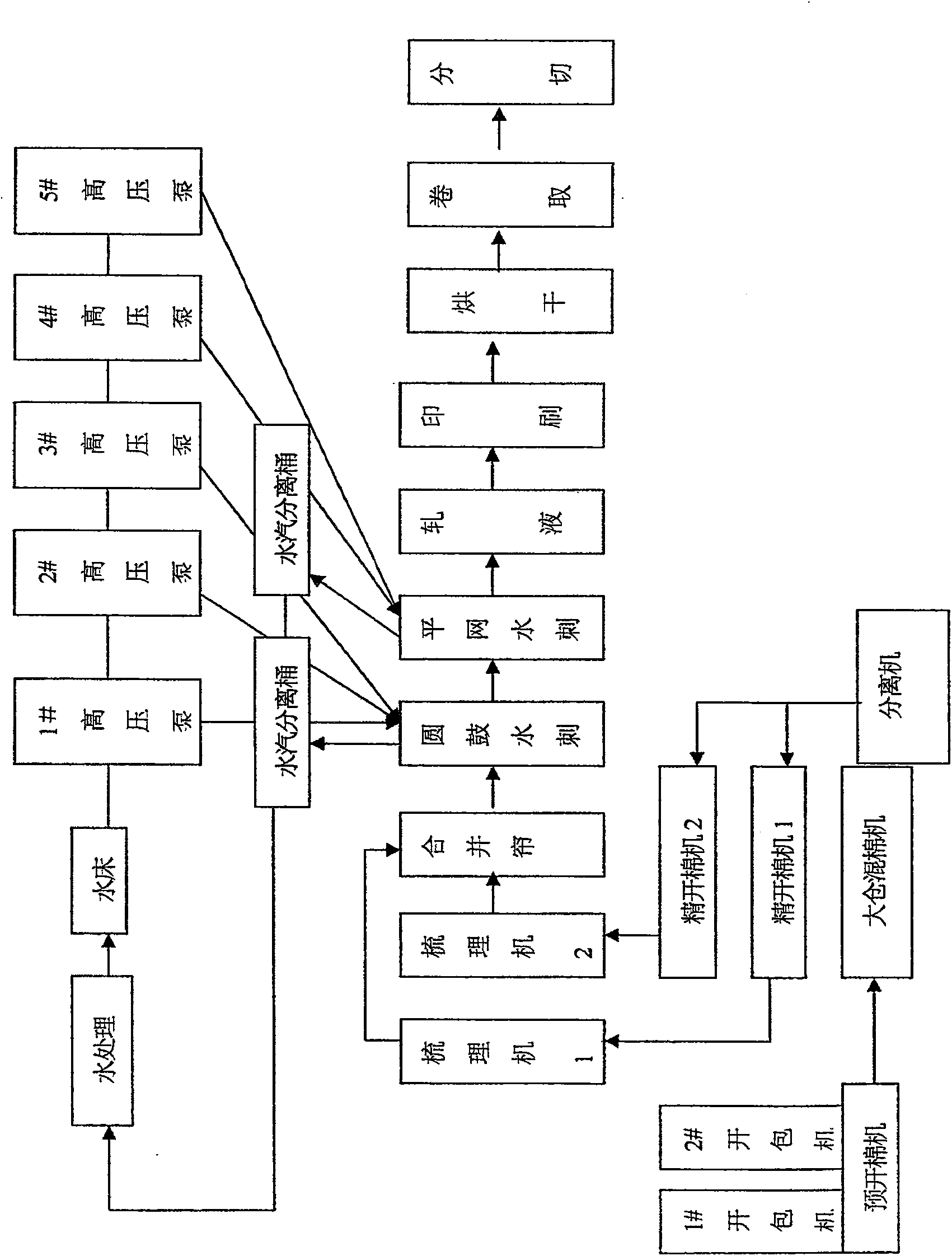

[0025] Such as figure 1 As shown, the process of spunlace cloth includes: unpacking, pre-opening, blending, fine opening, carding and merging, spunlace, padding, drying, coiling, slitting, and packaging. The production equipment of the present invention needs to use 2 bale openers, 1 pre-opener, 1 multi-bin cotton blending machine, 1 cotton blender, 2 fine cotton openers, 2 cotton feeding machines, 2 carding machines, Laying machine 1 set, drum type spunlace machine 1 set, flat screen spunlace machine 1 set, printing gluing machine 1 set, cylinder dryer 1 set, rotary screen dryer 1 set, cloth storage Stand, 1 coiler, 14 high-pressure pump components, 2 water supply pumps, 1 set of water filtration system, 2 slitting machines.

[0026] 1. Unpacking: 2 sets of unpacking machines, using 1.5D×38cm animal protein regenerated fiber (such as the fiber produced by Yancheng Shengjia Textile Ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com