Subcritical pressure pouring boiler furnace

A steam injection boiler and subcritical technology, applied in steam boilers, forced flow steam boilers, steam generation, etc., can solve problems such as difficult mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

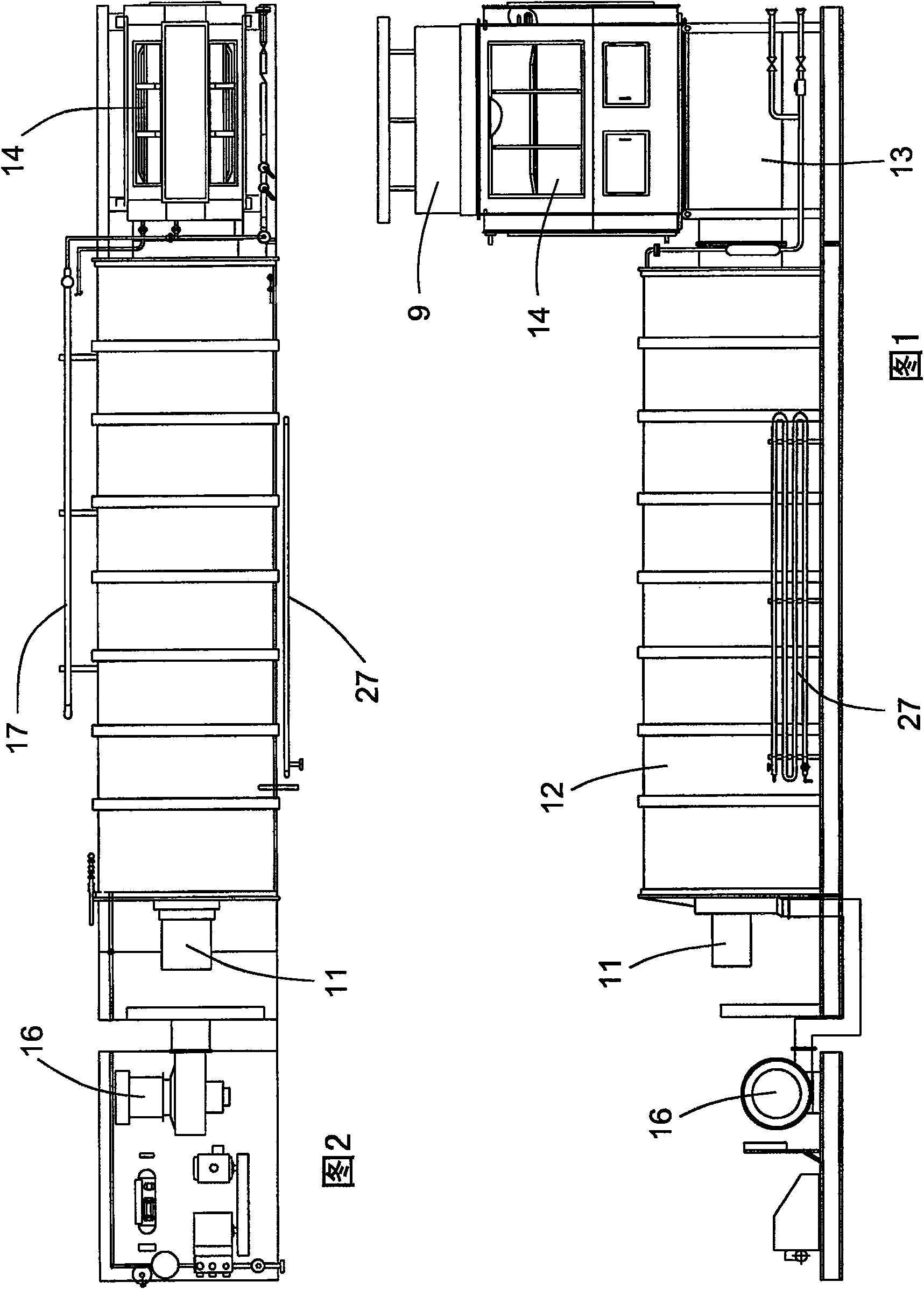

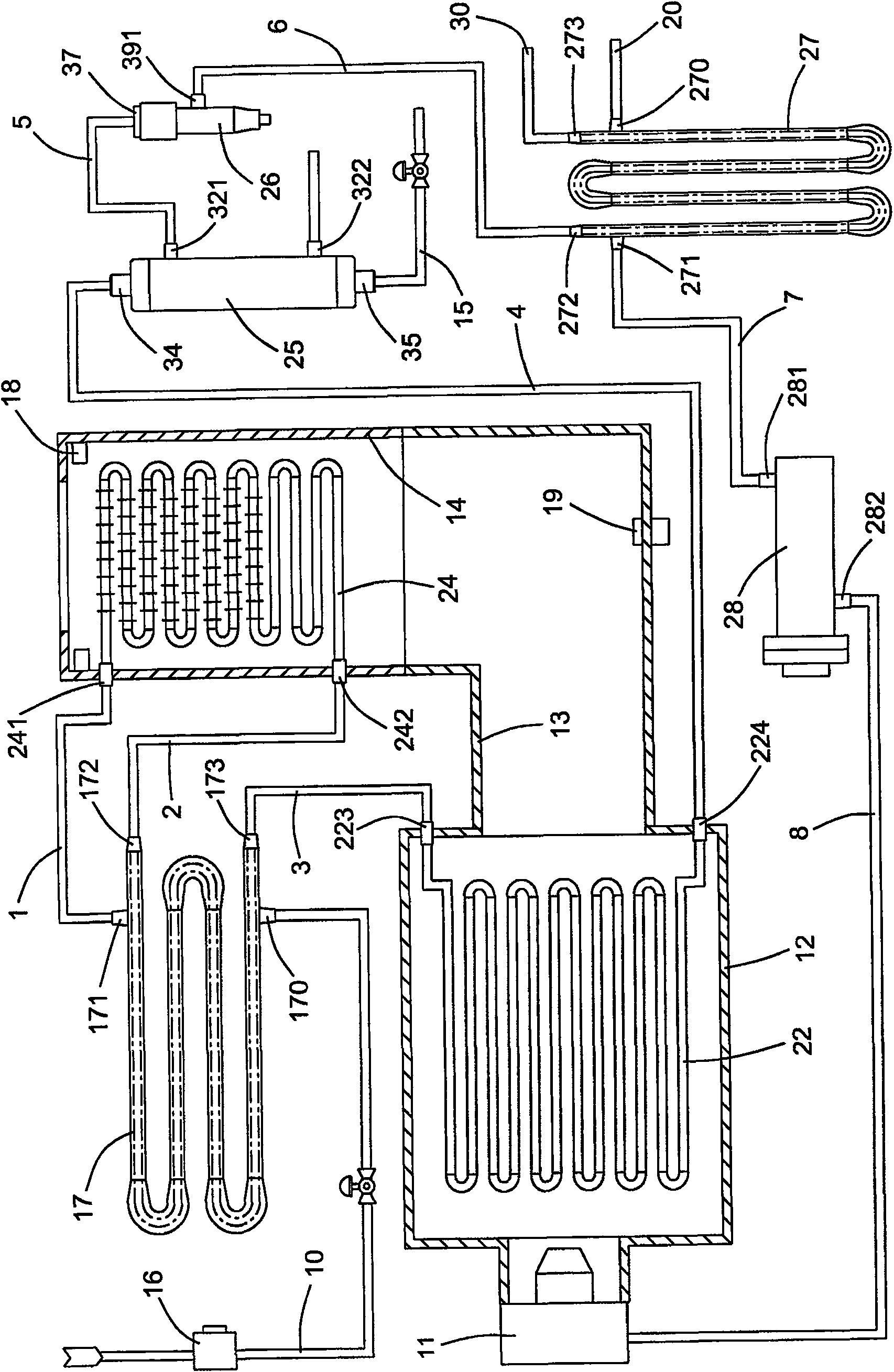

[0026] Label in the figure

[0027] 1 Pipeline 1 2 Pipeline 2 3 Pipeline 3

[0028] 4 Pipeline 4 5 Pipeline 5 6 Pipeline 6

[0029] 7 No. 7 pipe 8 No. 8 pipe 9 Chimney 10 Water supply pipe

[0030] 11 Burner 12 Radiant section 13 Transition section

[0031] 14 Convection section 15 Steam discharge pipe 16 Water pump

[0032] 17 feed water preheater 170 first shell side inlet 171 first shell side outlet

[0033] 172 The first tube pass inlet 173 The first tube pass exit

[0034] 18 Ultrasonic soot blower 19 Sewage outlet 20 Oil inlet pipe

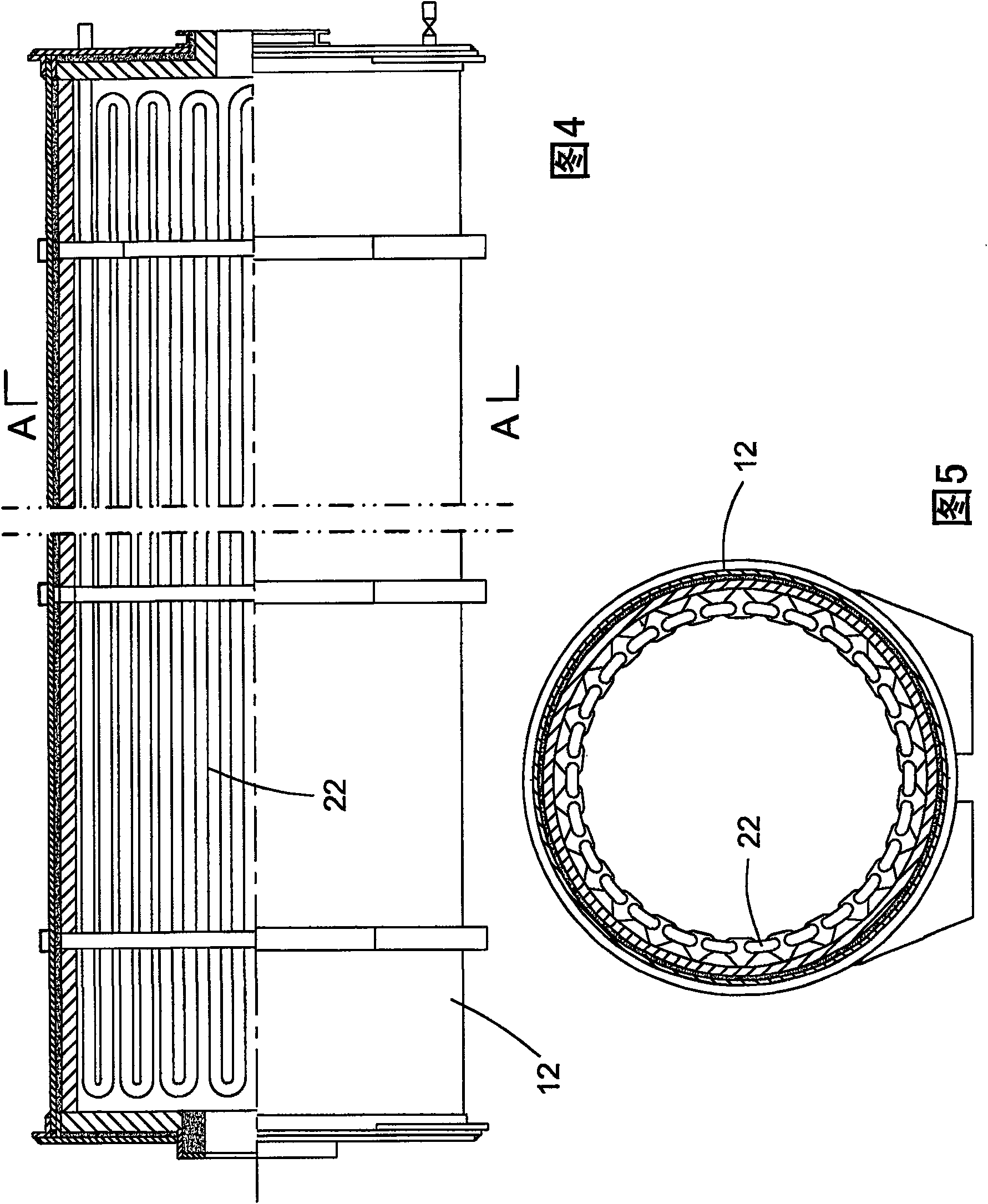

[0035] 22 radiation tube bundle 223 entrance 224 exit 23 light tube

[0036] 24 convection tube bundle 241 inlet 242 outlet

[0037] 25 Water separator 26 Steam filter 27 Fuel preheater

[0038] 270 second shell side entrance 271 second shell side exit

[0039] 272 Second tube pass inlet 273 Second tube pass exit

[0040] 28 electric heater 281 inlet 282 outlet 29 finned tube

[0041] 30 Sewage pipe 31 Top cover 32 Cylinder body 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com