Steam exhaust device for direct air-cooling unit

An air-cooled unit and steam exhaust technology, which is used in steam/steam condensers, lighting and heating equipment, etc., can solve the problems of increasing the construction and operation costs of direct air-cooling units, large overall engineering volume, and high construction costs, and can meet the requirements of condensing steam. Technical requirements, good economy, and the effect of reducing the amount of construction work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

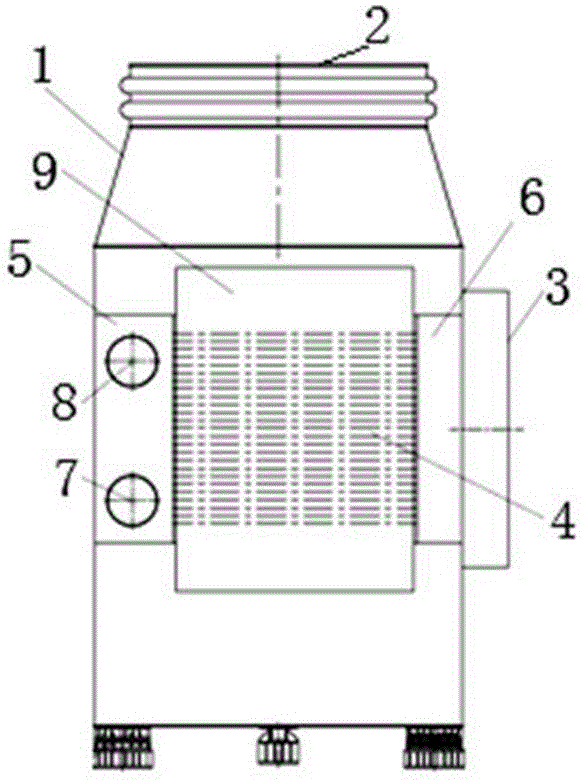

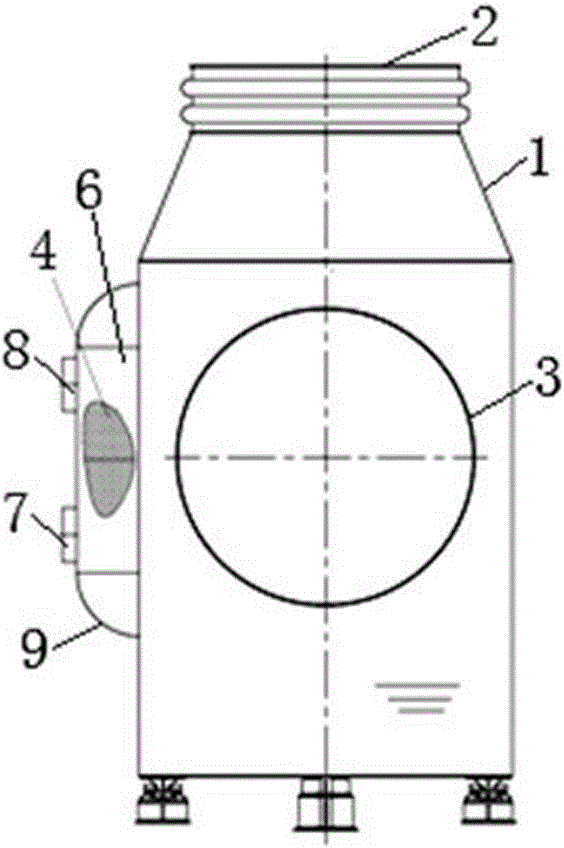

[0013] see figure 1 and figure 2 As shown, the present invention is an exhaust device for a direct air-cooling unit, which includes an exhaust device body and an indirect wet-condensing condenser (hereinafter referred to as a wet-condensing condenser).

[0014] Wherein, the exhaust device body is mainly composed of an exhaust casing 1, an exhaust inlet 2, an exhaust outlet 3, a hot well and a support arranged on the exhaust casing 1. The exhaust steam inlet 2 is located on the top of the exhaust steam housing 1 . The exhaust steam outlet 3 is located on the side wall of the exhaust steam casing 1 below the exhaust steam inlet 2 . There is also a steam condensation window on the side wall of the exhaust casing 1 below the exhaust inlet 2, and the condensation window and the exhaust outlet 3 are located on the adjacent side wall of the exhaust casing 1, and are also located Between the steam path stroke of the steam inlet 2 and the steam exhaust outlet 3, the radial angle be...

Embodiment 2

[0018] The invention relates to a steam exhaust device for a direct air cooling unit, which comprises a steam exhaust device body and a wet cooling condenser.

[0019] Among them, the main body of the exhaust device is mainly composed of an exhaust shell, an exhaust inlet, an exhaust outlet, a hot well and a support arranged on the exhaust shell. The exhaust steam inlet is at the top of the exhaust casing. The exhaust steam outlet is located on the side wall of the exhaust steam casing below the exhaust steam inlet. There is also a steam condensation window on the side wall of the exhaust shell below the exhaust steam inlet. The steam condensation window and the exhaust steam outlet are located on the adjacent side wall of the exhaust Between the steam passage strokes of the steam outlet, the radial angle between the centerline of the condensation window and the centerline of the exhaust outlet in the exhaust casing is less than 180°, preferably 90°.

[0020] The wet cooling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com