Automatic spraying production line

An automatic spraying and production line technology, applied in spray booths, spraying devices, etc., can solve problems such as inconvenience and waste of resources, and achieve the effects of compact and compact layout, reduced transshipment costs, and reduced production line costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

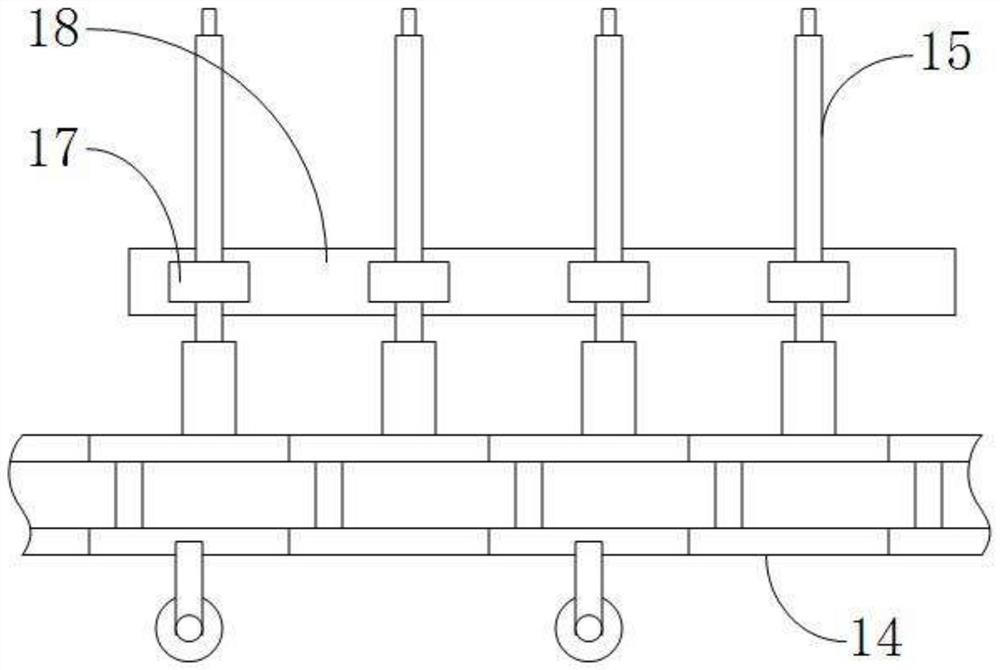

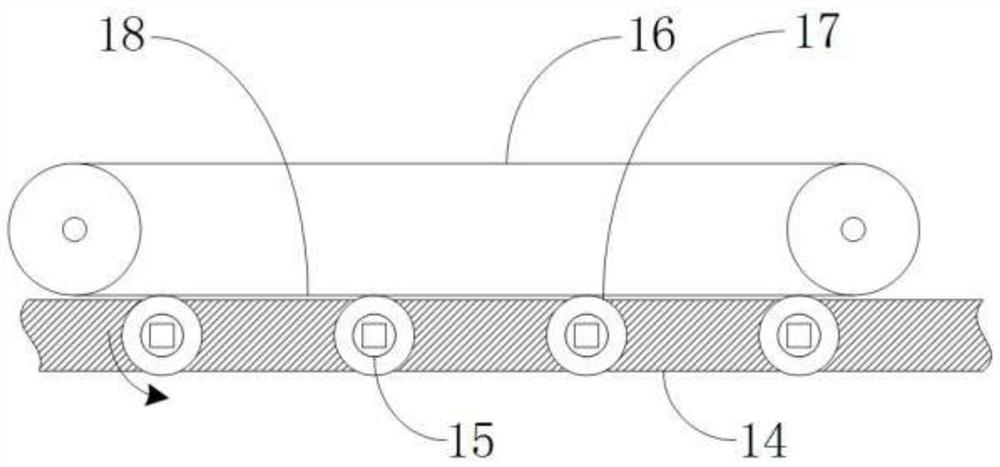

[0026] The invention provides an automatic spraying production line. The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to make it easier to understand and grasp.

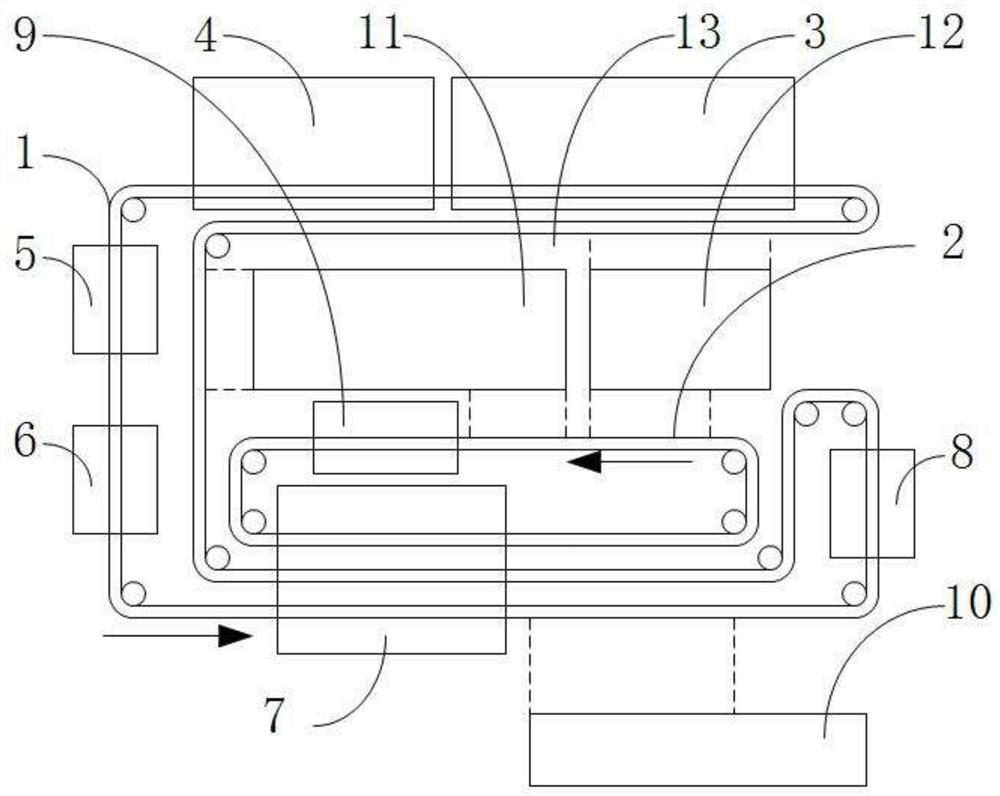

[0027] Automated spraying production line, such as figure 1 As shown, it includes the first circulation line 1, the second circulation line 2 and several working areas.

[0028] Among them, the workstation area includes loading fixture area 3, wiping workpiece area 4, electrostatic dust removal area 5, varnish spraying area 6, curing area 7, color paint spraying area 8, topcoat spraying area 9, electroplating area 10, and laser engraving area 11. Unloading and switching area 12.

[0029] The first circulation line 1 passes through the loading fixture area 3, the wiping workpiece area 4, the electrostatic dust removal area 5, the varnish spraying area 6, the curing area 7, the paint spraying area 8, and the curing area 7 in sequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com