Low temperature preparation method for alcohol heat assistant ferro-electricity film

A ferroelectric thin film and thin film technology, which is applied in the field of low-temperature preparation of ferroelectric thin films assisted by alcohol heat, can solve problems affecting material reliability and stability, film cracking, and deterioration of film dielectric properties, so as to improve material properties, Mild reaction conditions and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

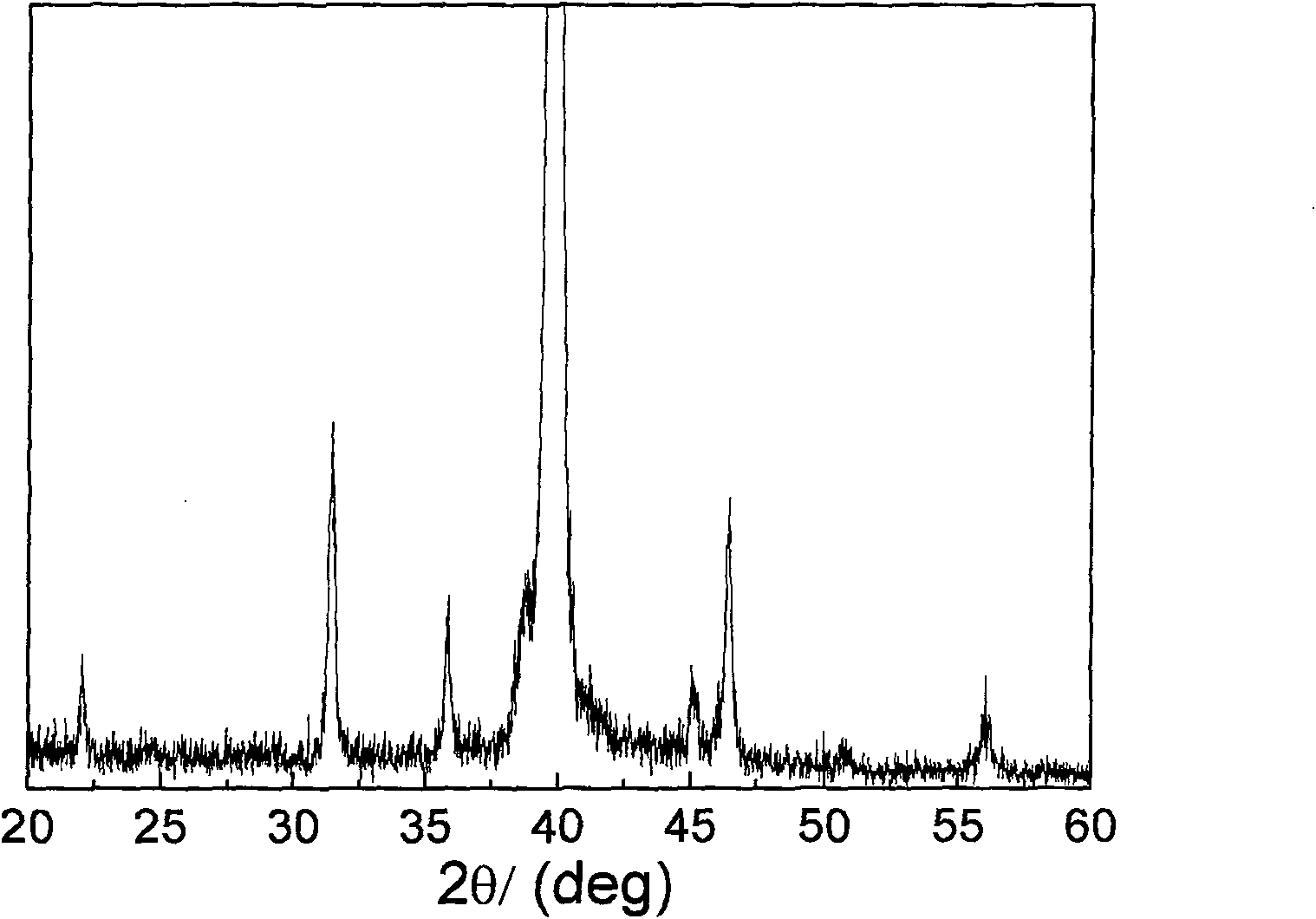

[0023] Preparation of Ba(Ti 1-x Zr x )O 3 , (x=0-0.9) ferroelectric thin film:

[0024] The chemical raw material used is barium acetate [Ba(CH 3 COO) 2 ], zirconium isopropoxide [Zr(OC 3 h 7 ) 4 ] and titanium isopropoxide [Ti(OC 3 h 7 ) 4 ], the solvent is glacial acetic acid and ethylene glycol ether. First heat barium acetate (according to a certain stoichiometric ratio) in glacial acetic acid solution to boiling, stop heating after 5 minutes, and cool to room temperature, the molar ratio of Ba to glacial acetic acid is 1:10. Then the mixed solution of zirconium isopropoxide and titanium isopropoxide, ethylene glycol ethyl ether and acetylacetone (AcAc) is added to barium-containing glacial acetic acid solution, wherein: the molar ratio of Ti to AcAc is 1:2, (iso Titanium propoxide + zirconium isopropoxide): the molar ratio of ethylene glycol ether is 1:10. Finally, ethylene glycol ether was added to adjust the concentration of the final solution to 0.3M. Afte...

example 2

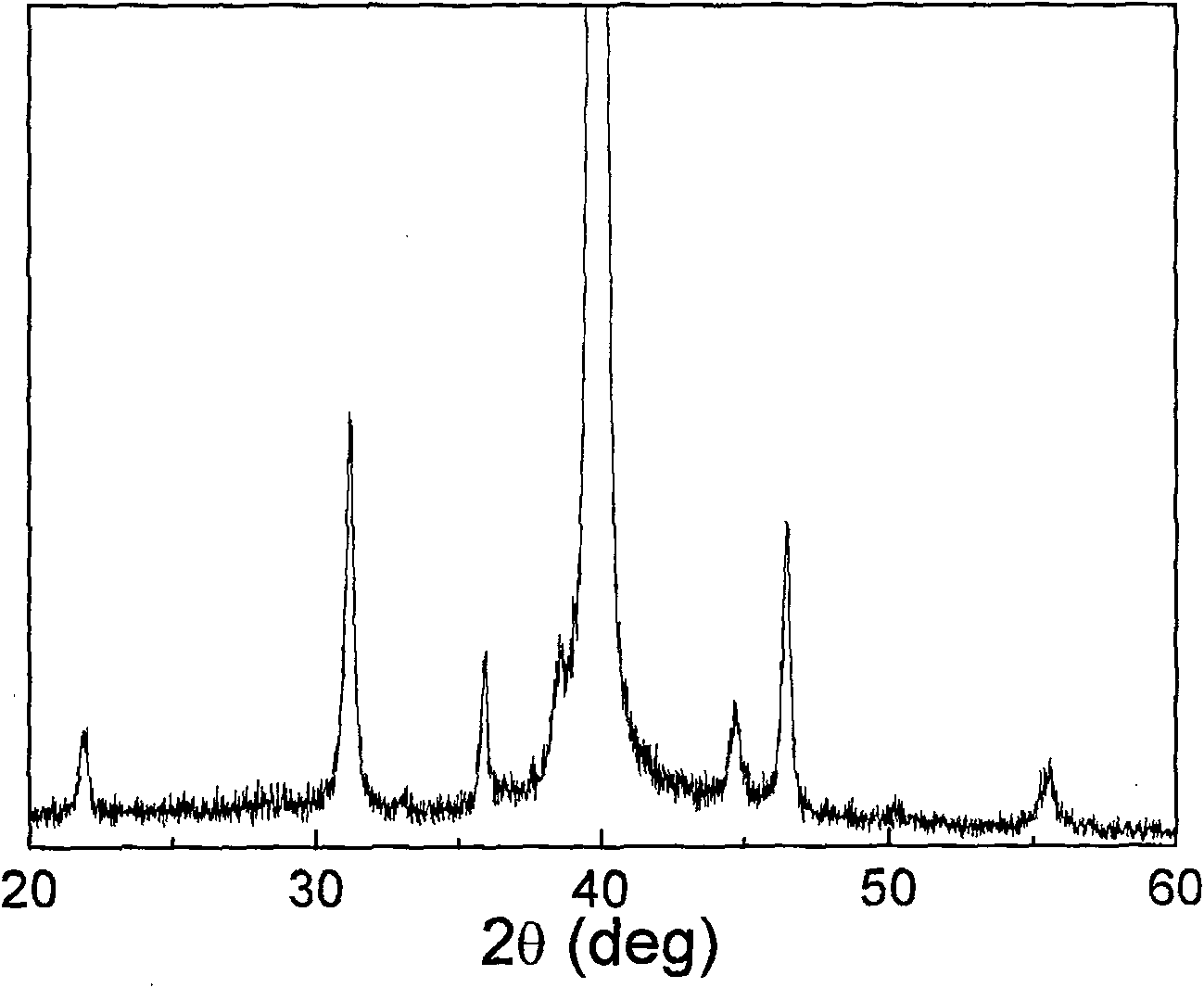

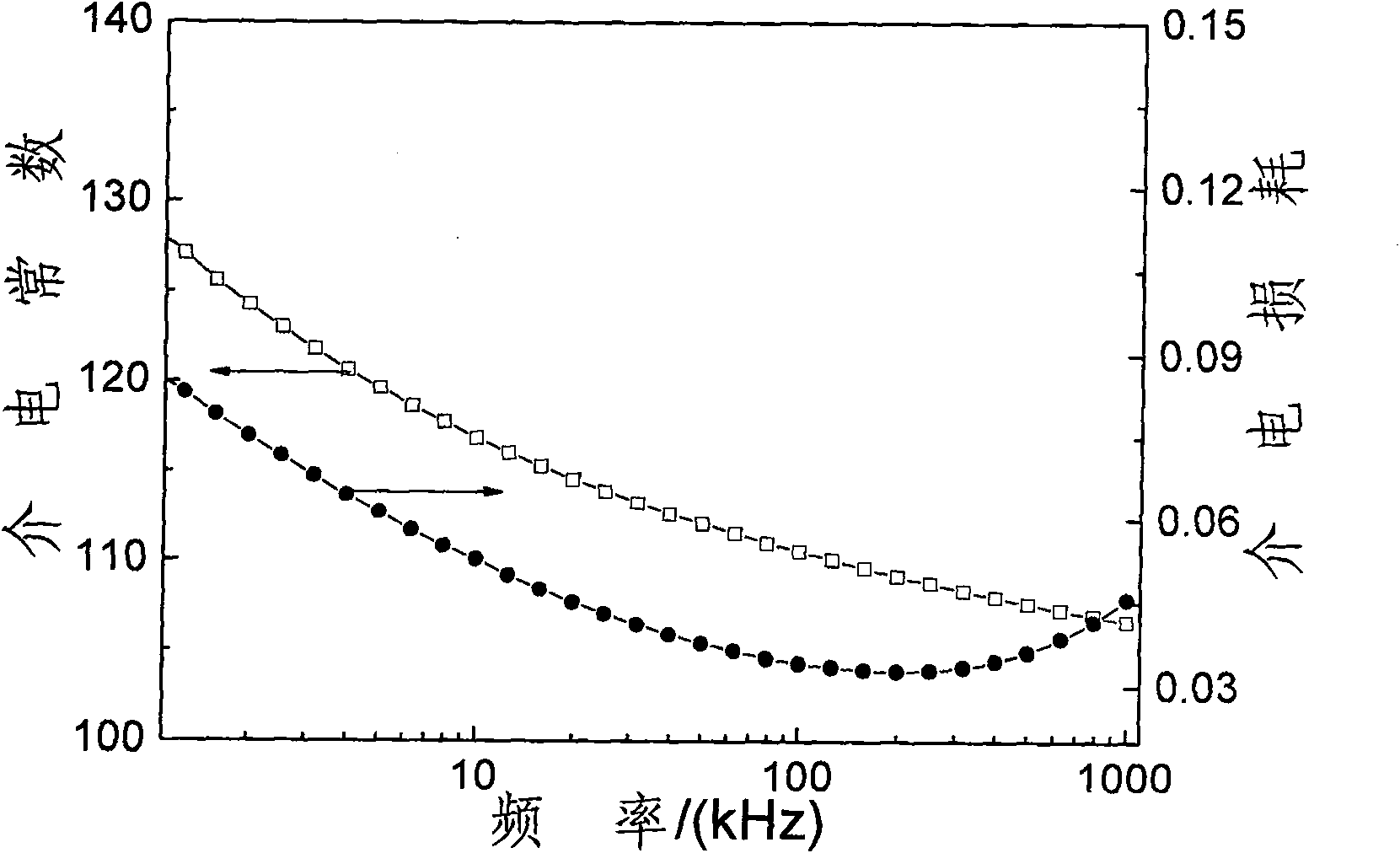

[0028] Preparation of BaTiO 3 Ferroelectric thin film:

[0029] The chemical raw material used is barium acetate [Ba(CH 3 COO) 2] and titanium isopropoxide [Ti(OC 3 h 7 ) 4 ], the solvent is glacial acetic acid and ethylene glycol ether. First heat barium acetate (according to a certain stoichiometric ratio) in glacial acetic acid solution to boiling, stop heating after 5 minutes, and cool to room temperature, the molar ratio of Ba to glacial acetic acid is 1:10. Then add the mixed solution of titanium isopropoxide, ethylene glycol ethyl ether and acetylacetone (AcAc) into the barium-containing glacial acetic acid solution, wherein: the molar ratio of Ti to AcAc is 1:2, titanium isopropoxide: ethylene diacetone The molar ratio of alcohol to ether is 1:10. Finally, ethylene glycol ether was added to adjust the concentration of the final solution to 0.3M. After standing for 24 hours, it was used to prepare the film.

[0030] The substrate used is Pt / Ti / SiO 2 / Si(100), ...

example 3

[0033] Preparation of BaTiO 3 Ferroelectric thin film:

[0034] The chemical raw material used is barium acetate [Ba(CH 3 COO) 2 ] and titanium isopropoxide [Ti(OC 3 h 7 ) 4 ], the solvent is glacial acetic acid and ethylene glycol ether. First heat barium acetate (according to a certain stoichiometric ratio) in glacial acetic acid solution to boiling, stop heating after 5 minutes, and cool to room temperature, the molar ratio of Ba to glacial acetic acid is 1:10. Then add the mixed solution of titanium isopropoxide, ethylene glycol ethyl ether and acetylacetone (AcAc) into the barium-containing glacial acetic acid solution, wherein: the molar ratio of Ti to AcAc is 1:2, titanium isopropoxide: ethylene diacetone The molar ratio of alcohol to ether is 1:10. Finally, ethylene glycol ether was added to adjust the concentration of the final solution to 0.3M. After standing for 24 hours, it was used to prepare the film.

[0035] The substrate used is Pt / Ti / SiO 2 / Si(100),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com