Method for producing basic magnesium carbonate with boric sludge

A technology of magnesium carbonate and boron mud, applied in magnesium carbonate, magnesium hydroxide and other directions, can solve problems such as being unsuitable for industrial production, and achieve the effect of shortening production cycle, energy saving production cycle and creating value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

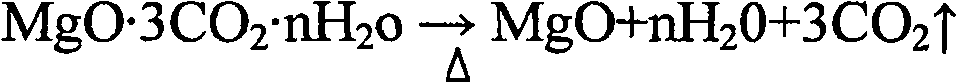

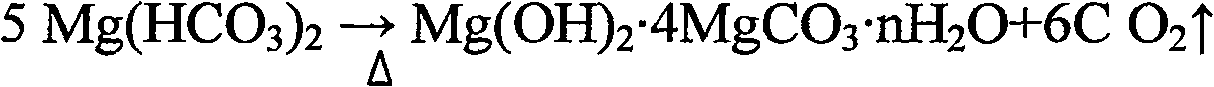

Method used

Image

Examples

Embodiment 1

[0030] Weigh 1 kg of Liaoning Kuandian boron mud No. 1 and put it into the furnace, heat it to 500°C for 0.8 hours, take it out and cool it to room temperature.

[0031] Then use 6 liters of water and boron mud to mix into a slurry, pour it into a 10 liter stainless steel reaction kettle, add 6 grams (0.1% of the water amount) of wood vinegar, and start stirring at room temperature to feed 5kg / cm 2 CO 2 After reacting for 6 hours, detect the reaction solution with pH test paper, stop the reaction at pH=7.0, discharge and filter.

[0032] Get mother liquor and be heated to 98 ℃, be incubated 35 minutes, then filter and air-dry at room temperature, the white solid that obtains weighs 420g product, and the yield is 42% according to the amount of water-containing boron slime, and the yield is 42% according to the amount of dehydrated (30%) boron slime The yield is 60%, and the magnesium mud is dried to obtain 335g.

Embodiment 2

[0034] Weigh 1 kg of Jilin Ji'an City boron mud No. 1 and put it into the furnace, heat it to 300°C for 2.0 hours, take it out and cool it to room temperature.

[0035] Then mix 4.5 liters of water with boron mud to form a slurry, pour it into a 10 liter stainless steel reaction kettle, add 4.5 grams (0.1% of the water amount) of wood vinegar, and start stirring at room temperature to feed 3.5kg / cm 2 CO 2 After reacting for 6 hours, detect the reaction solution with pH test paper, stop the reaction at pH=7.0, discharge and filter.

[0036] Get mother liquor and be heated to 100 ℃, be incubated 15 minutes, then filter and air-dry at 50 ℃, the white solid basic magnesium carbonate 410g that obtains, yield is 41% by boron mud amount, the (10% water) of dehydrated boron mud 45.5%, to get magnesium mud 361g.

Embodiment 3

[0038] Weigh 1Kg of Liaoning Kuandian boron mud No. 2 and put it into the furnace, heat it to 400°C for 1.5 hours, take it out and cool it to room temperature.

[0039] Then use 5 liters of water and boron mud to mix into a slurry, pour it into a 10 liter stainless steel reaction kettle, add 5 grams (0.1% of the water amount) of wood vinegar, and start stirring at room temperature to feed 4kg / cm 2 CO 2 After reacting for 6 hours, detect the reaction liquid with pH test paper, stop the reaction at pH = 7.0, discharge and filter.

[0040] Get the mother liquor and heat it to 99°C, keep it warm for 20 minutes, then filter and air-dry at 80°C to obtain 470g of dry basic magnesium carbonate, the yield is 47% of boron mud, remove water (20% moisture), 58.7% of boron mud , to get magnesium mud 460g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com