Hydraulicity modulation aluminophosphate color cement

A technology of aluminophosphate cement and aluminophosphate, applied in the field of inorganic materials, can solve the problems of high alkalinity of colored Portland cement, limited performance by chemical nature, etc., achieve high color fastness, inhibit efflorescence, improve The effect of strength and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

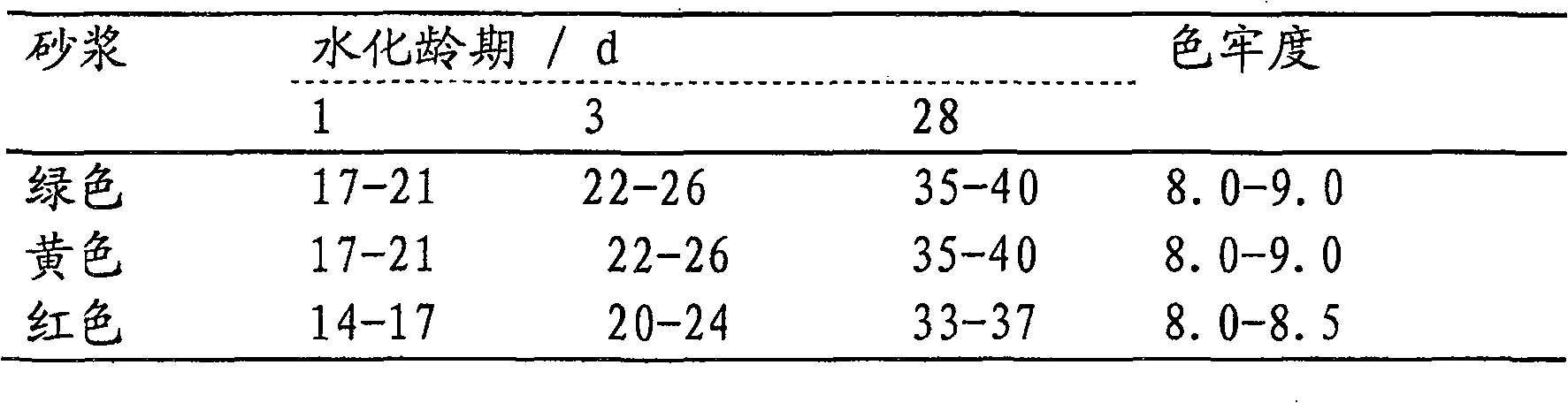

Examples

Embodiment 1

[0039] Embodiment 1, green aluminophosphate cement, the content of each component by weight percentage is:

[0040] Aluminophosphate cement: 89.0

[0041] Chromium Oxide Green Pigment: 3.4

[0042] Activated siliceous minerals (680°C roasted pyrophyllite): 6.7

[0043] Hydrophobic agent (aluminum phosphate / iron phosphate mixed in 1:1 ratio) 0.9

Embodiment 2

[0044] Embodiment 2, yellow aluminophosphate cement, the content of each component by weight percentage is:

[0045] Aluminophosphate cement: 85.0

[0046] Iron oxide yellow pigment: 7.0

[0047] Activated siliceous minerals (silica gel, Qingdao Ocean Chemical Factory): 7.0

Embodiment 3

[0049] Embodiment 3, red aluminophosphate cement, the content of each component by weight percentage is:

[0050] Aluminophosphate cement: 90.0

[0051] Scarlet Pigment: 1.0

[0052] Activated siliceous minerals (roasted pyrophyllite at 680°C): 6.0

[0053] Hydrophobic agent (acrylate): 1.9

[0054] The hydraulic modulation aluminophosphate colored cement of the present invention is a self-contained product. The so-called "modulation" refers to the "sintered" colored cement. There are no special requirements for the modulation process of the hydraulically modulated aluminophosphate colored cement of different colors.

[0055] When the colored aluminophosphate cement of the present invention is mixed with water in use, due to the "hydrophobic agent", it is better to use strong stirring under conditions, so as to enhance the plasticity of the slurry and facilitate the performance of the performance.

[0056] The pH value of the colored aluminophosphate cement slurry of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

| color price | aaaaa | aaaaa |

| color price | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com