A kind of ultra-thin flexible cement decorative board and preparation method thereof

A decorative board and cement technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problem that the cement decorative board is easily damaged during handling or installation, the ultra-thin cement decorative board is hard and brittle, and lacks flexibility. and other problems, to achieve the effect of improving anti-flooding performance, improving bending toughness and waterproof performance, and good compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

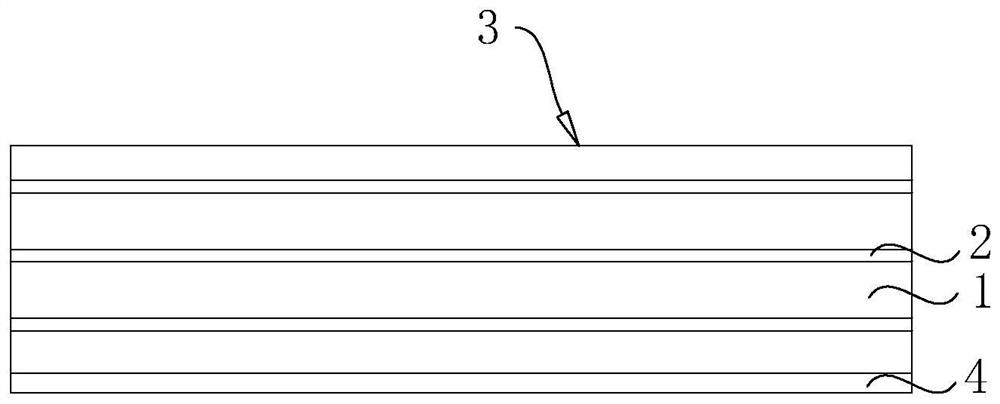

Image

Examples

Embodiment 1

[0060] A preparation method of an ultra-thin flexible cement decorative board, comprising the following steps:

[0061] S1, the preparation of mixing agent:

[0062] S11, 5Kg magnesium chloride is added in the mixing tank, while adding water, measure solution salinity by Baume meter, when the salinity of solution reaches 22 ° Be after, stop adding water;

[0063] S12, add 0.05Kg of color paste, and after stirring evenly, add 22.5Kg of polyvinyl alcohol, stir evenly, and make the mixed water agent;

[0064] S2, preparation of mortar:

[0065] 10Kg cement, 20Kg magnesia, 20Kg fine sand, 0.5Kg water reducer, 10Kg fly ash, 0.3Kg short fiber are premixed in proportion in turn, and after stirring for 15 minutes, the mortar is prepared;

[0066] S3. Mix the mixing water agent and the mortar according to the mass ratio of 3:8, and stir for 5-8 minutes to obtain a composite slurry;

[0067] S4. Spray a layer of composite slurry in the first mold, spread a layer of non-alkali mesh cl...

Embodiment 2

[0070] A preparation method of an ultra-thin flexible cement decorative board, comprising the following steps:

[0071] S1, the preparation of mixing agent:

[0072] S11, 1Kg magnesium chloride is added in the mixing tank, while adding water, measure solution salinity by Baume meter, after the salinity of solution reaches 25 ° of Be, stop adding water;

[0073] S12, add 0.07Kg of color paste, and after stirring evenly, add 4.5Kg of polyvinyl alcohol, stir evenly, and make mixing water;

[0074] S2, preparation of mortar:

[0075] 5Kg cement, 10Kg magnesia, 10Kg fine sand, 0.1Kg superplasticizer, 5Kg fly ash, 0.1Kg short fiber were premixed in proportion in turn, and after stirring for 15 minutes, the mortar was prepared;

[0076] S3. Mix the mixing water agent and the mortar according to the mass ratio of 3:6, and stir for 5 minutes to obtain a composite slurry;

[0077] S4. Spray a layer of composite slurry in the first mold, spread a layer of non-alkali mesh cloth on the ...

Embodiment 3

[0080] A preparation method of an ultra-thin flexible cement decorative board, comprising the following steps:

[0081] S1, the preparation of mixing agent:

[0082] S11, 3Kg magnesium chloride is added in the mixing tank, while adding water, measure solution salinity by Baume meter, when the salinity of solution reaches 22 ° Be, stop adding water;

[0083] S12, add 0.1Kg of color paste, and after stirring evenly, add 13.5Kg of polyvinyl alcohol, stir evenly, and make the mixed water agent;

[0084] S2, preparation of mortar:

[0085] 7.5Kg of cement, 15Kg of magnesium oxide, 15Kg of fine sand, 0.3Kg of water reducer, 7.5Kg of fly ash, and 0.2Kg of short fibers were premixed in proportion in sequence, and after stirring for 20 minutes, the mortar was prepared;

[0086] S3. Mix the mixing water agent and the mortar according to the mass ratio of 3:7, and stir for 5 minutes to obtain a composite slurry;

[0087] S4. Spray a layer of composite slurry in the first mold, spread ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com