Blowing powder for molten steel secondary refining and preparation method and methods for using same

A technology for external refining and molten steel furnace, which is applied in the field of injection powder for external refining of molten steel and its preparation and application. It can solve the problems of insufficient matching of smelting time and affect the production efficiency of steelmaking process, etc., and achieve shortening of operation time and improvement of operation. Efficiency, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

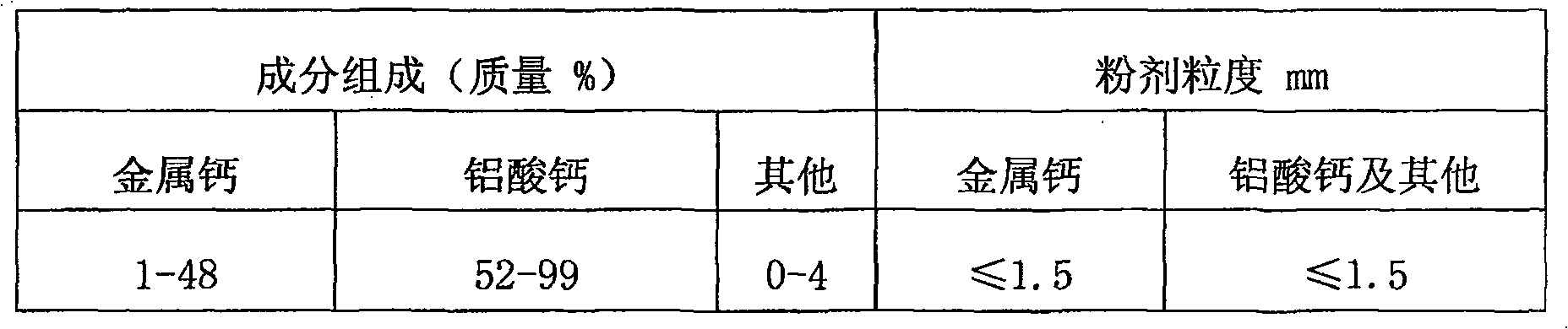

Embodiment 1

[0024] The slab is produced on a 150-ton converter in the A steel plant. The steel type is STSC, and the tapping temperature is 1670°C. After aluminum deoxidation and alloying in the ladle, the average oxygen in the steel is 25ppm, and the sulfur is 260ppm. The direct injection powder refining process is adopted. Its calcium-calcium aluminate powder mass ratio is: Ca: 20%, calcium aluminate is 80%, the Al in this calcium aluminate 2 o 3 The CaO content is 38%, and the CaO content is 62%. The calcium-calcium aluminate composite powder of the above components is sprayed into molten steel. The test results are counted for 100 furnaces, and the powder dosage is 1.0kg / t steel; ladle sampling analysis [O] content It is 8.9ppm, [S] content is 185ppm, so the content of oxygen and sulfur in steel after molten steel refining according to this technology is better than that of traditional LF furnace refining.

Embodiment 2

[0026] The slab is produced on a 150-ton converter in the A steel plant. The steel type is STSC, and the tapping temperature is 1670°C. After aluminum deoxidation and alloying in the ladle, the average oxygen in the steel is 25ppm, and the sulfur is 260ppm. The direct injection powder refining process is adopted. Its calcium-calcium aluminate powder mass ratio is: Ca: 1%, calcium aluminate content is 99%, the Al in this calcium aluminate 2 o 3 The CaO content is 50%, and the calcium-calcium aluminate composite powder of the above components is sprayed into molten steel. The test results are counted for 100 furnaces, and the powder dosage is 1.0kg / t steel; the ladle is sampled to analyze the [O] content It is 8.9ppm, [S] content is 185ppm, so the content of oxygen and sulfur in steel after molten steel refining according to this technology is better than that of traditional LF furnace refining.

Embodiment 3

[0028] The slab is produced on a 150-ton converter in the A steel plant. The steel type is STSC, and the tapping temperature is 1670°C. After aluminum deoxidation and alloying in the ladle, the average oxygen in the steel is 25ppm, and the sulfur is 260ppm. The direct injection powder refining process is adopted. Its calcium-calcium aluminate powder mass ratio is: Ca: 48%, calcium aluminate content is 52%, the Al in this calcium aluminate 2 o 3 The CaO content is 60%, and the CaO content is 40%. The calcium-calcium aluminate composite powder of the above components is sprayed into molten steel. The test results are counted for 100 furnaces, and the powder dosage is 1.0kg / t steel; the ladle is sampled to analyze the [O] content It is 8.9ppm, [S] content is 185ppm, so the content of oxygen and sulfur in steel after molten steel refining according to this technology is better than that of traditional LF furnace refining.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com