Etching liquid composition

A technology of composition and etching solution, applied in the preparation of surface etching composition, detergent composition, detergent mixture composition, etc., can solve the problems of generating etching residue, complicated operation, unable to obtain pattern edge shape, etc., To achieve the effect of improved wettability and long liquid life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] Hereinafter, the present invention will be described in more detail by citing examples and comparative examples, but these do not limit the present invention in any way. In addition, the etching rate described below is the numerical value at the time of performing etching operation several times with the same liquid until reaching a stable etching rate.

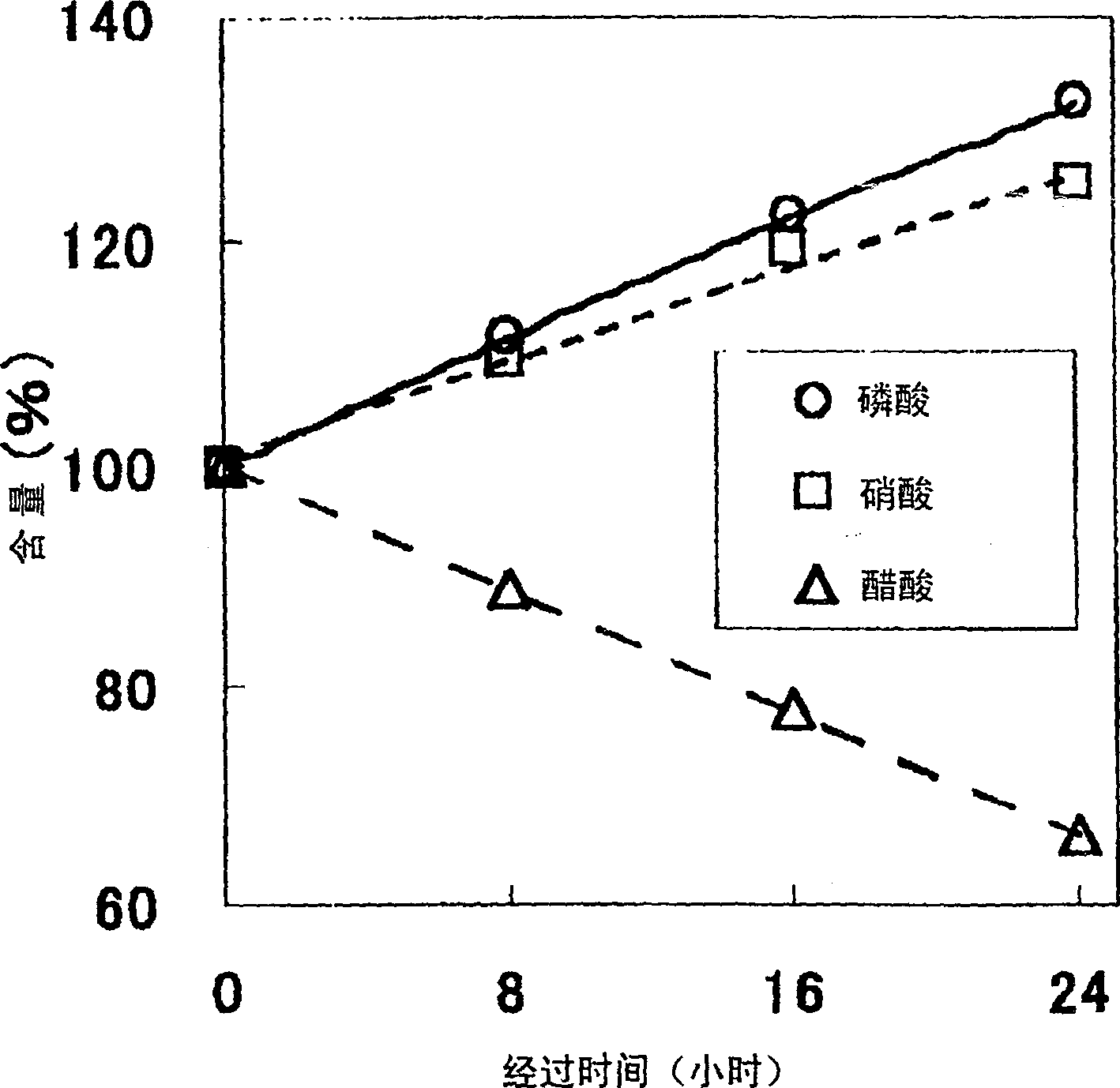

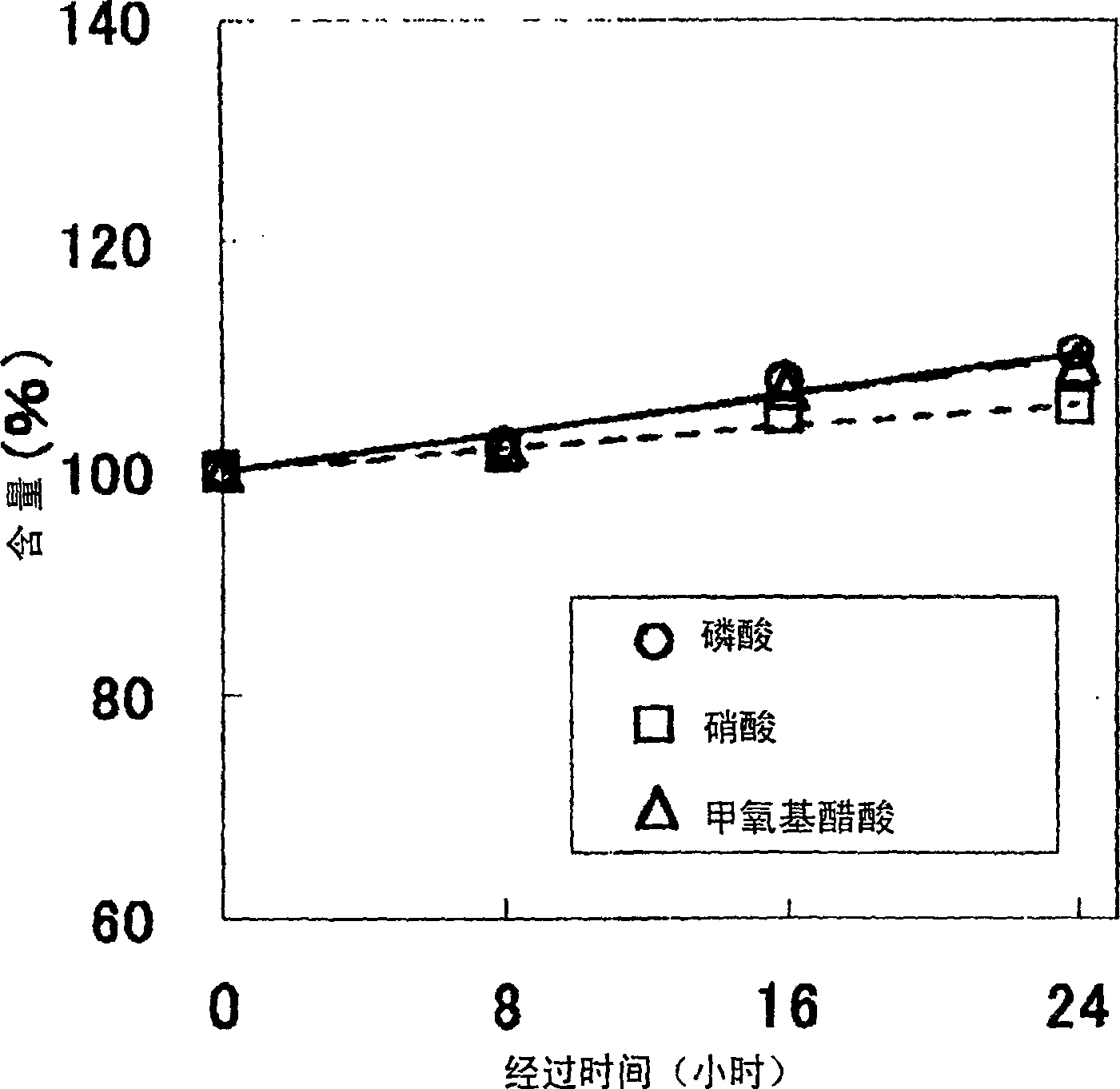

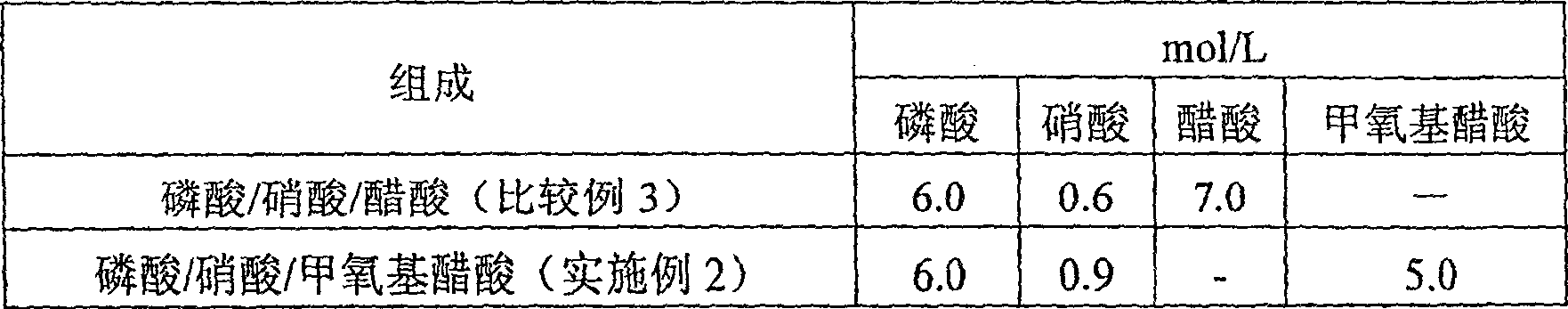

[0043] [Evaluation Test 1] Effect of Methoxyacetic Acid

[0044] In order to confirm the effect of methoxyacetic acid as a substitute for acetic acid, a composition consisting of 6.0 mol / L of phosphoric acid, 1.0 mol / L nitric acid, and water and a composition to which 5.0 mol / L acetic acid or methoxyacetic acid were added were compared. Solubility in phosphoric acid / nitric acid system, etching rate (material to be etched: pure silver foil (a square with a side length of 2cm, thickness 50μm), liquid temperature: 30°C, 1 minute after reaching a stable etching rate, without stirring) etc., and the results are shown in Ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com