Grids and method of manufacture

A manufacturing method and gate technology, applied in semiconductor/solid-state device manufacturing, electrical components, semiconductor devices, etc., can solve problems such as the inability to accurately control the line width at the bottom of the gate, and achieve the limitation of lithography resolution and reliability High and stable electrical parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

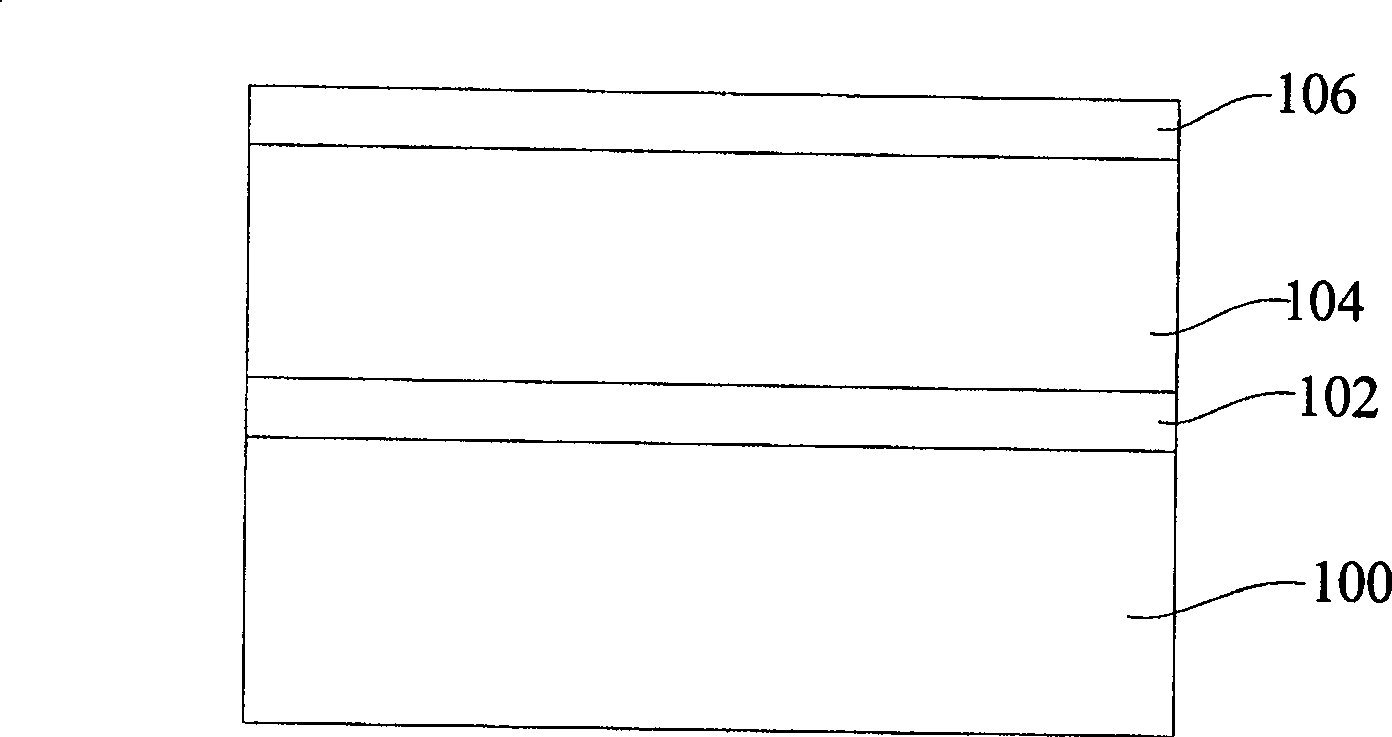

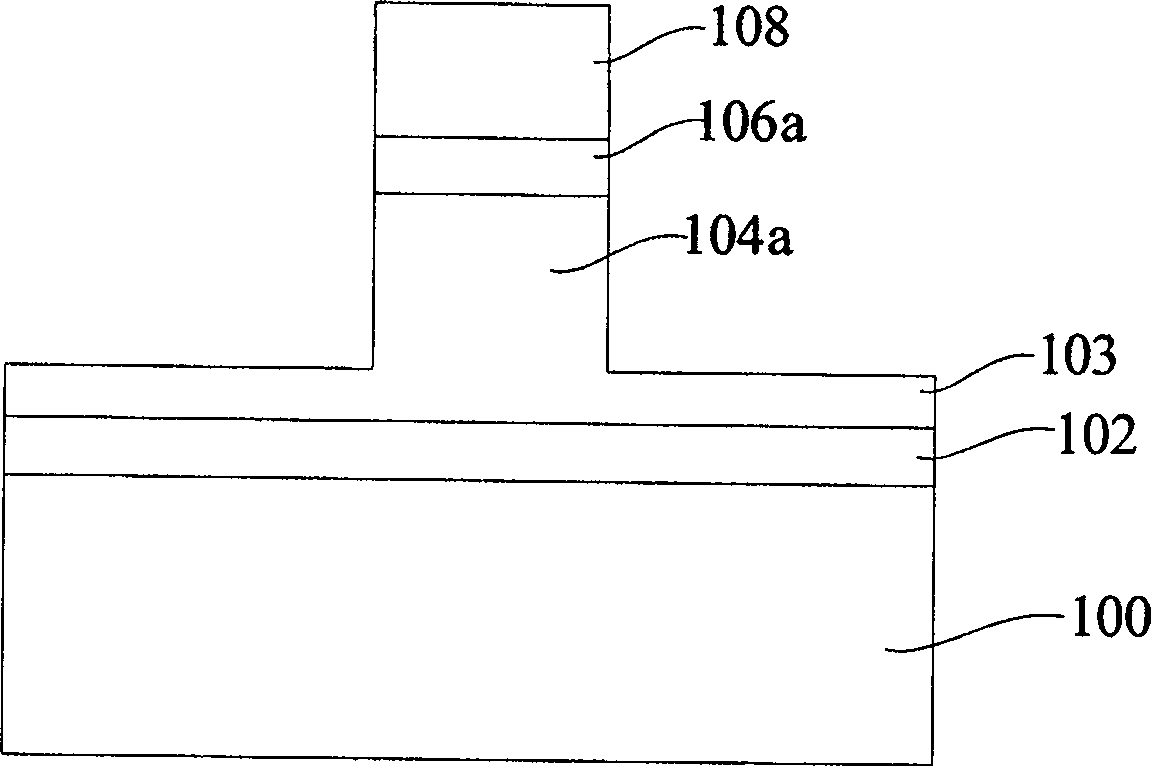

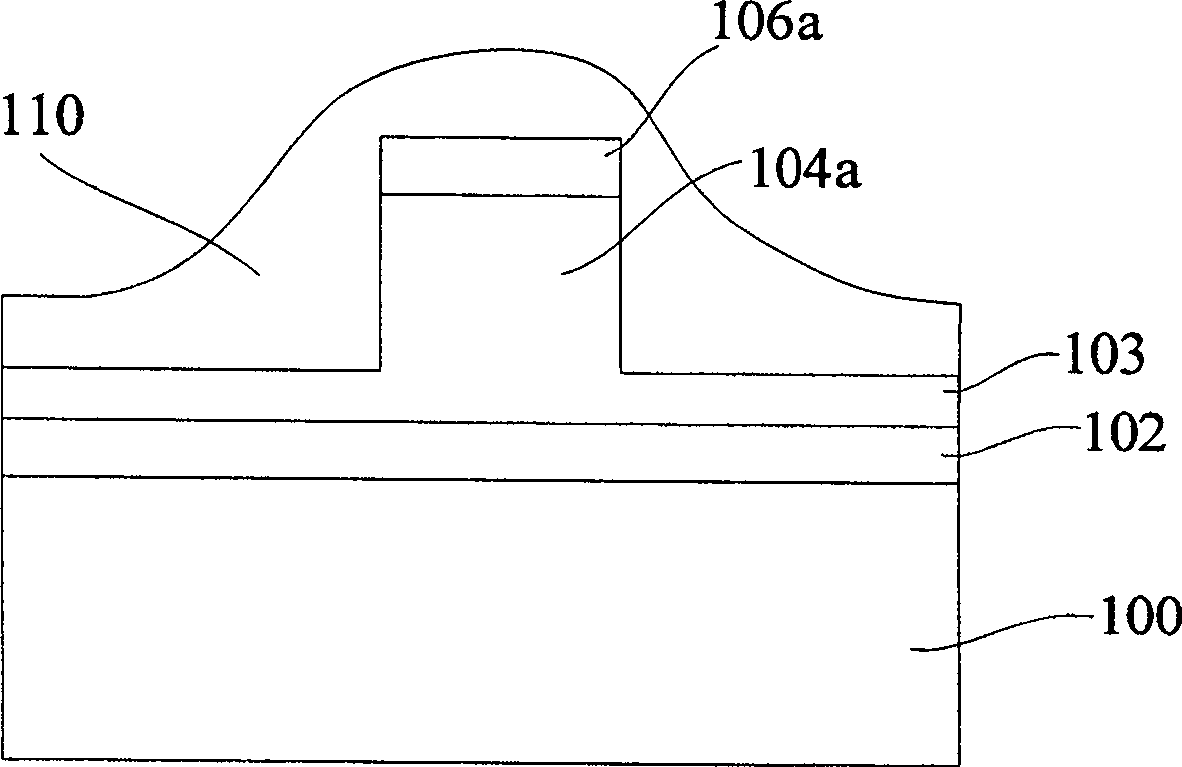

[0024] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] Figure 7 It is a flow chart of an embodiment of the method for forming a gate with a groove at the bottom of the present invention.

[0026] like Figure 7 As shown, firstly, a semiconductor substrate is provided ( S100 ). The semiconductor base is one of polysilicon, single crystal silicon, amorphous silicon, silicon on insulating layer, silicon germanium composition and gallium arsenide. Doping N-type impurities or P-type impurities into the semiconductor substrate to form a conductive channel of the device. The surface of the semiconductor substrate has a thin oxide layer, the thickness of the oxide layer is 1 to 100 nm, and the formation method of the oxide layer is high temperature thermal oxidation or deposition. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com