Method for improving sulphur dioxide clearance

A sulfur dioxide and removal rate technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of high operating cost and low efficiency, and achieve large processing capacity, high processing efficiency, and low operating cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

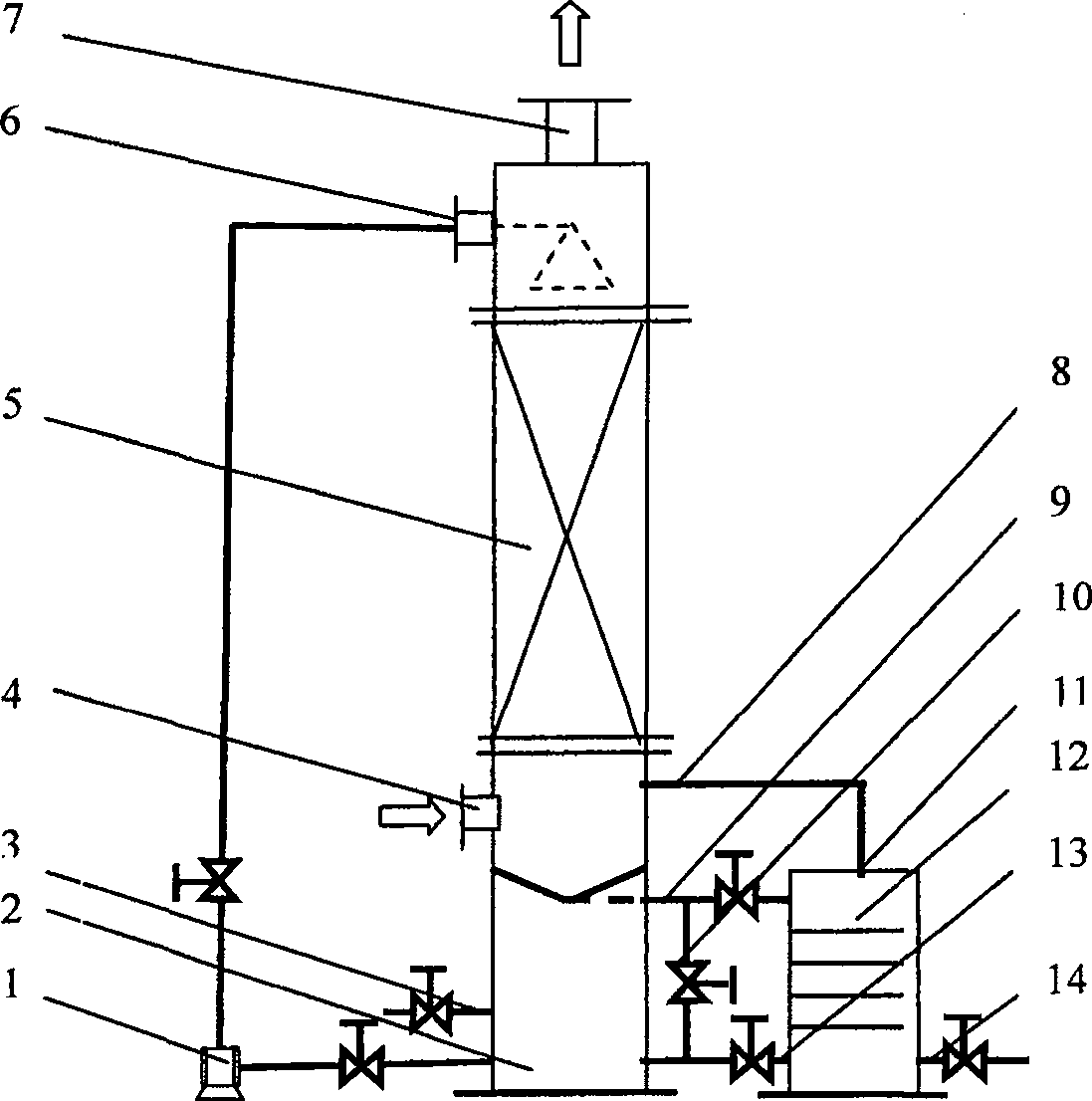

[0034] The absorption tower used in the present invention is a spray tower 5, the lower part of the spray tower is provided with an air inlet 4, the liquid outlet 9 of the absorption tower, the top of the spray tower is provided with an air outlet 7, and the upper part of the spray tower is provided with an absorption tower liquid inlet Port 6, between the absorption tower liquid inlet 6 and the air inlet 4 is a reaction chamber, and the bottom of the spray tower is a circulation tank 2, and the circulation tank is not directly connected with the reaction chamber, and the circulation tank is provided with Drain port 3; the liquid outlet 9 of the absorption tower communicates with the liquid inlet 11 of the electrocatalytic oxidation reactor 12 provided with a valve in the electrocatalytic oxidation reactor 12, and the top of the electrocatalytic oxidation reactor is also provided with a connection with the reaction chamber The gas communication pipe 8 connected to the room, the...

Embodiment 2

[0045] Embodiment 2: other conditions are the same as embodiment 1, pulse power supply, pulse frequency is 100Hz, average current density 8A / dm 2 .

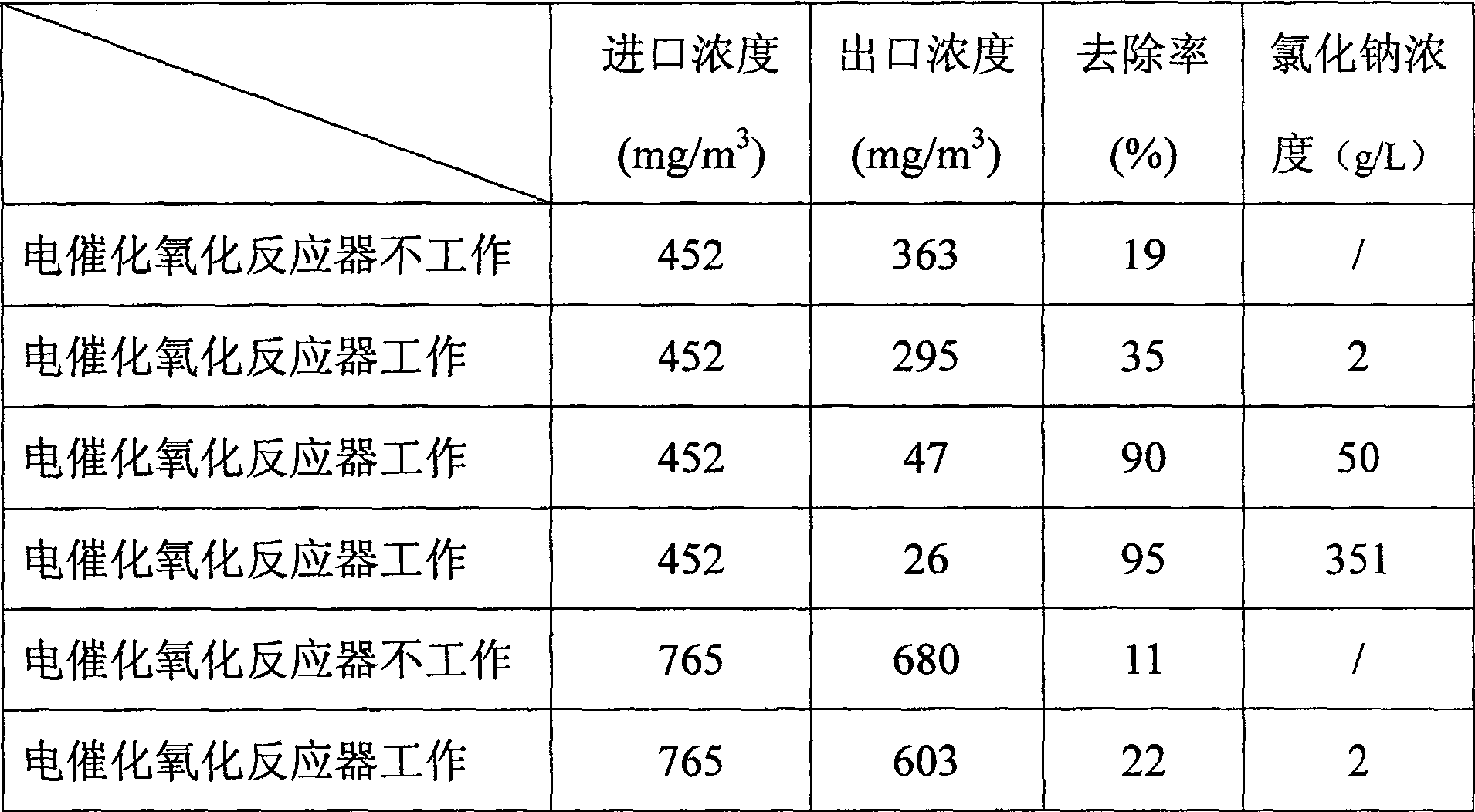

[0046] The experimental results are shown in Table 2.

[0047] Table 2

[0048]

Embodiment 3

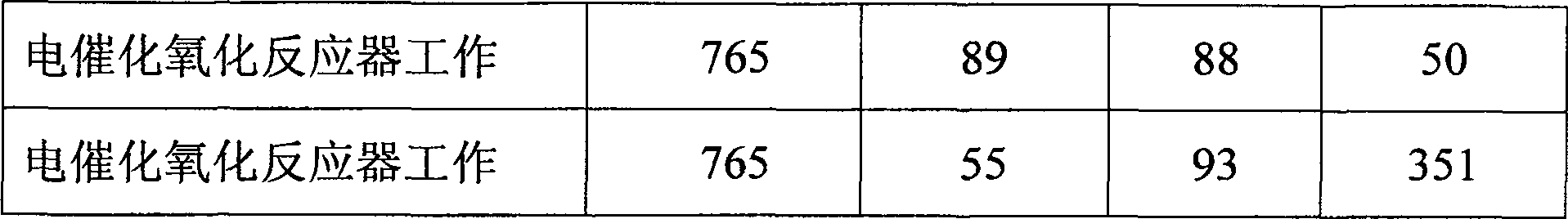

[0049] Embodiment 3: other conditions are with embodiment 1, and absorbent changes concentration into 100g / L calcium chloride solution, and experimental result is as shown in table 3:

[0050] table 3

[0051]

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com