Ultra-low hydrogen basic welding rod for P92 steel welding

A basic electrode, ultra-low hydrogen technology, used in welding media, welding equipment, welding/cutting media/materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] All embodiment welding rods are all made by common welding rod pressure coating machine:

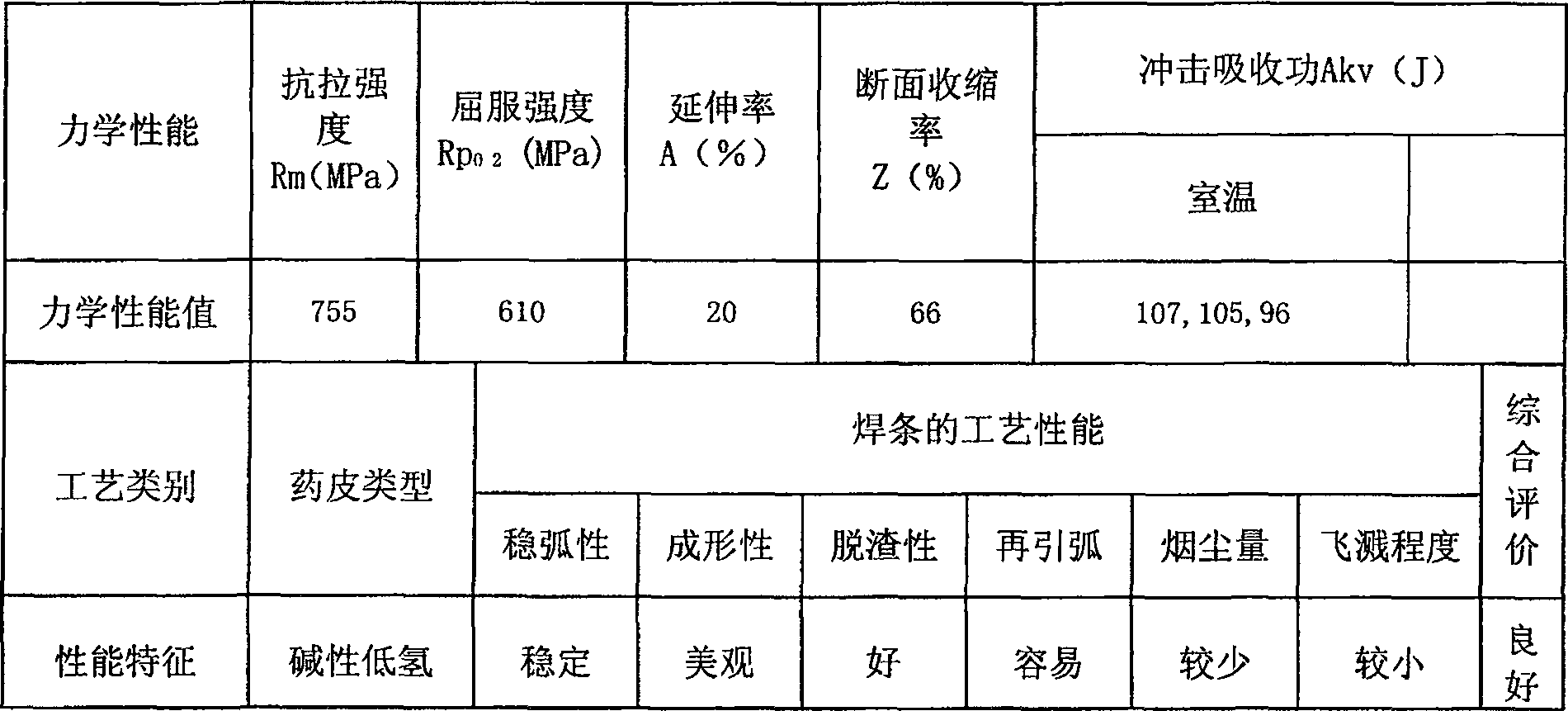

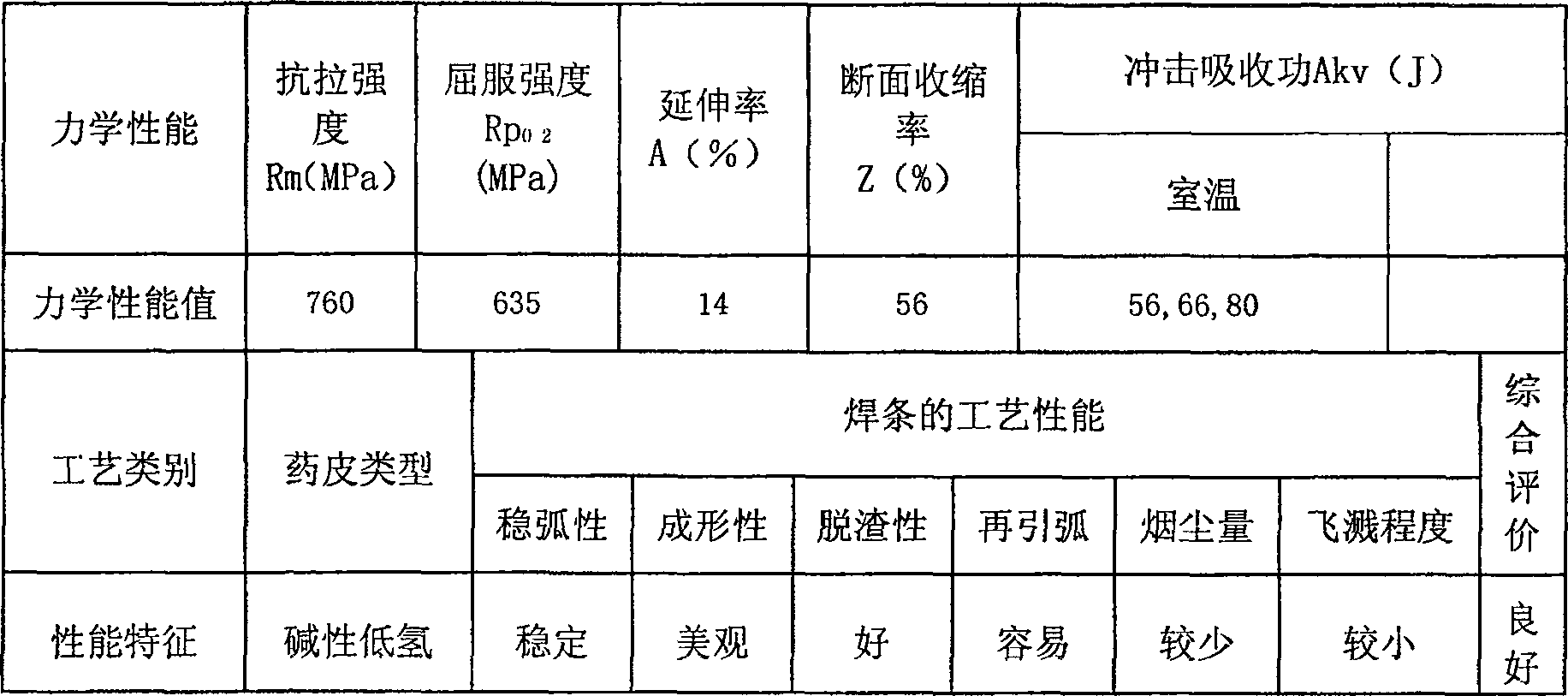

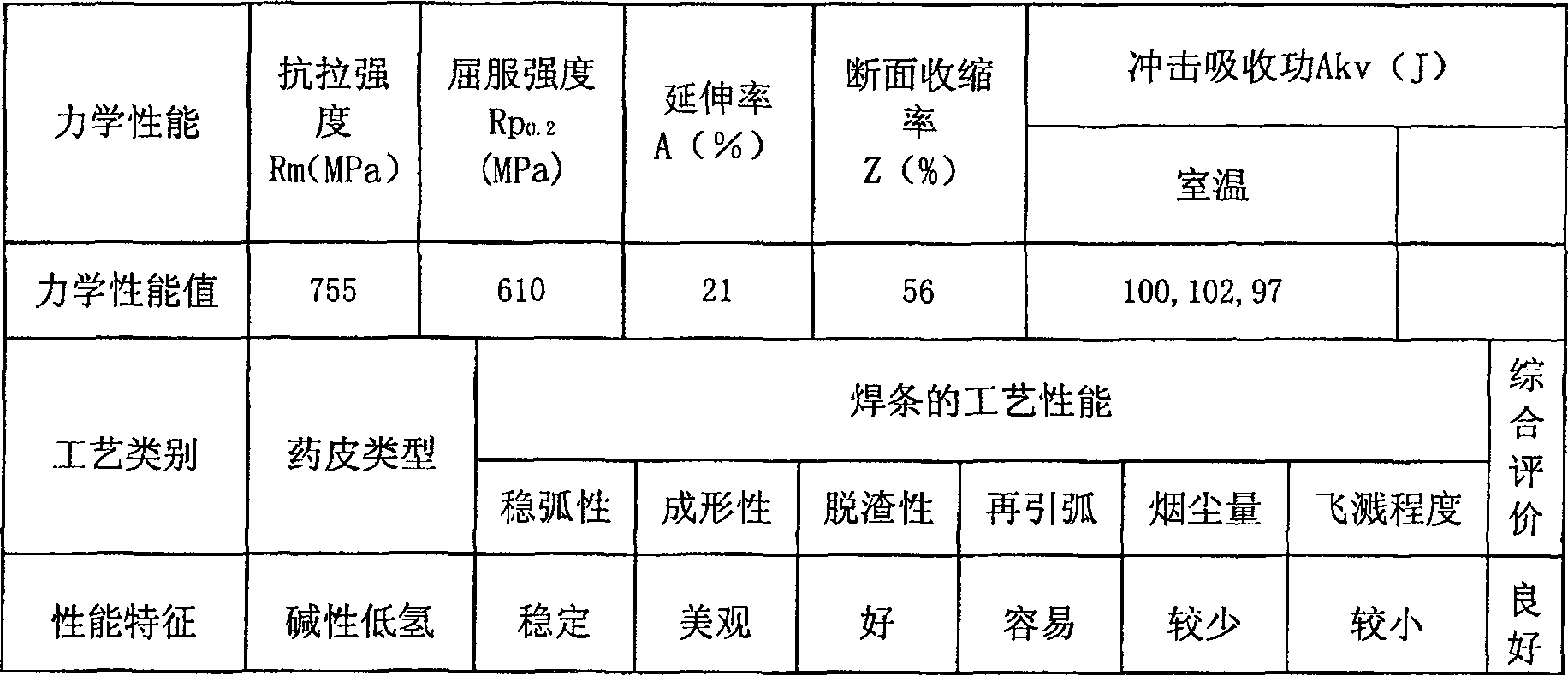

[0025] 1. Choose Φ2.5 high chromium molybdenum steel wire rod as the steel core. Take 20 grams of ferromanganese, 40 grams of ferrosilicon, 15 grams of aluminum, 30 grams of nickel powder, 10 grams of quartz, 30 grams of ferro-niobium, 5 grams of ferro-vanadium, 50 grams of titanium dioxide, 200 grams of fluorite, 600 grams of marble, a total of 1000 grams And 40 grams of water glass, put into the powder mixer and mix for 10 minutes, then add the mixed powder in the welding rod press coater. Pressed into electrodes, the welding process parameters are: electrode drying (°C h): 350×2; preheating temperature (°C): 150-200; interlayer temperature (°C): 200-250; welding current (A): 110~130; welding voltage (V): 25~28; post-weld heat treatment specification (℃ h): 770±10×2~4; heating rate (℃ / h): 100~120; cooling rate (℃ / h ): 120~150. The results of mechanical properties are shown in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com