Electrostatic spraying antirust oil

An electrostatic spraying, anti-rust oil technology, applied in the petroleum industry, base materials, additives, etc., can solve problems such as surface corrosion of carbon steel plates, and achieve the effects of low production cost, improved flash point, and improved washability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

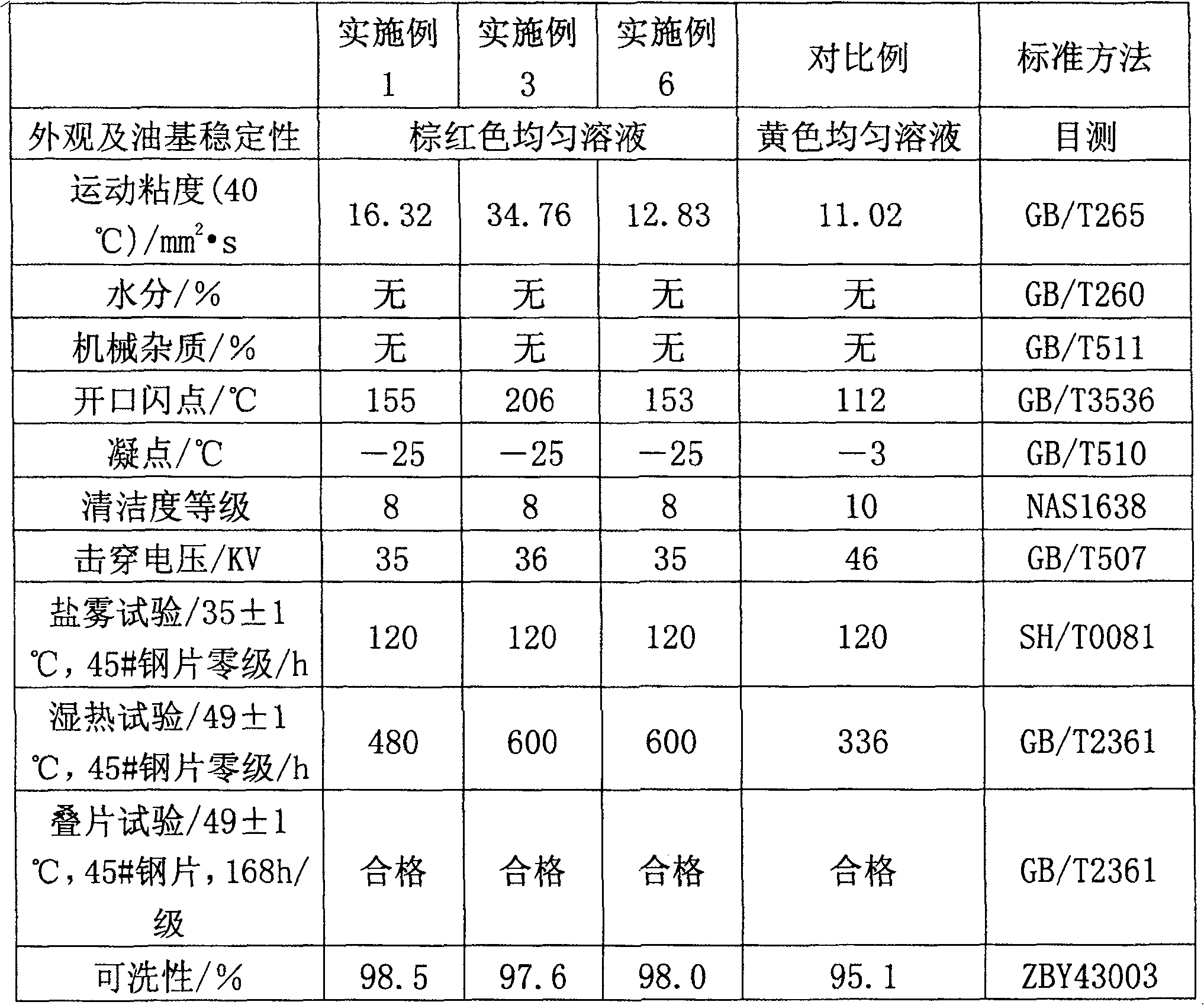

Examples

Embodiment 1

[0022] Add 75SN 85.0% to the reaction kettle, raise the temperature to 120°C for dehydration, add 5.0% calcium petroleum sulfonate, 4.0% barium petroleum sulfonate, 2.0% sodium petroleum sulfonate, keep stirring for 2 hours, cool down to 75°C, add Sorbitan monooleate 1.5%, benzotriazole 0.5%, 2,6-di-tert-butyl-4-cresol 2.0%, heat preservation and stirring for 0.5 hours, after passing the inspection, filter and discharge.

Embodiment 2

[0024] 100SN 79.5%, alkenyl succinic acid 8.0%, heptadecenyl imidazolinyl succinate 5.0%, sodium petroleum sulfonate 5.0%, nonylphenol polyoxyethylene ether 1.0%, methyltriazole 0.5 %, dialkyl diphenylamine 1.0%, production method is with embodiment 1.

Embodiment 3

[0026] 150SN 72.0%, calcium petroleum sulfonate 15.0%, sodium petroleum sulfonate 5.0%, alkenyl succinate 5.0%, sorbitan monostearate 2.0%, 2,6-di-tert-butyl-4- Cresol 1.0%, production method is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com