Ion injection uniformity control system and control method

An ion implantation and control system technology, which is applied in semiconductor/solid-state device manufacturing, discharge tubes, electrical components, etc., can solve problems such as the inability to meet the requirements of the semiconductor doping process of micro-nano devices, and achieve automatic adjustment of dose uniformity control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] Record a set of horizontal uniformity correction data according to the above method, as shown in Table 1 below:

[0046] Table 1: Unit: microampere

[0047] Correction

[0048] The number of corrections in Table 1 refers to the calculation formula for scanning voltage waveform correction

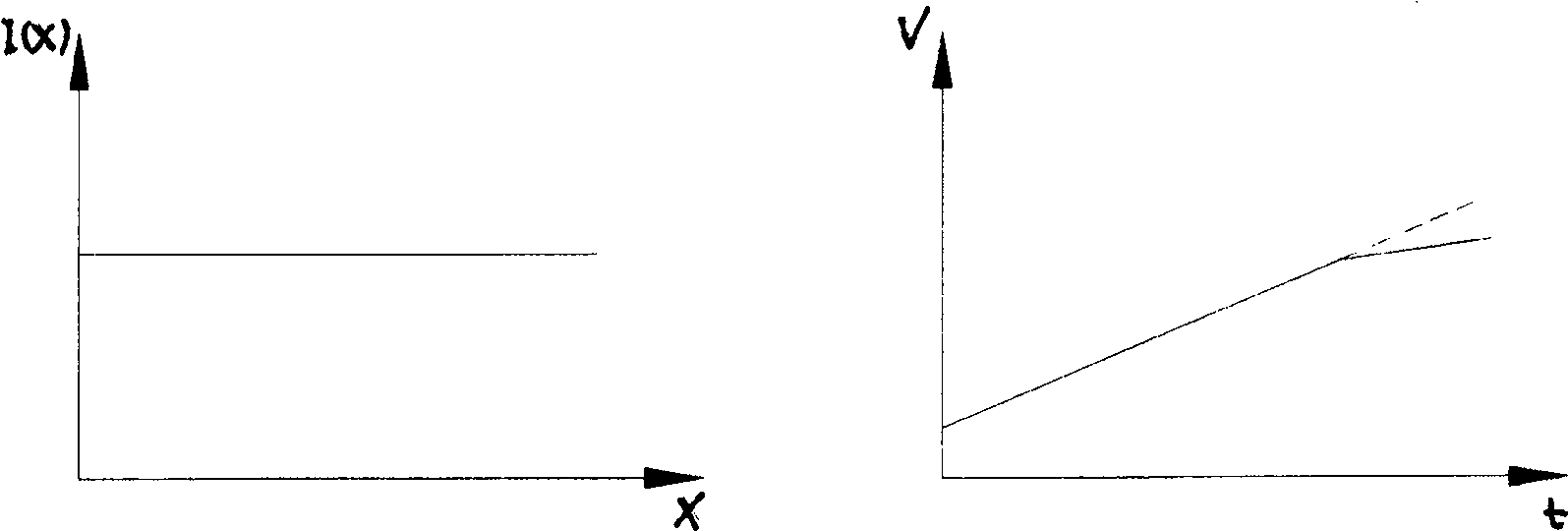

[0049] [dV(x) / dt] n =[dV(x) / dt] 0 ×I(x) / I 0 The number of corrections is taken as 3 times, and the scanning voltage waveform is not corrected at 0 times, which is a linear scanning waveform. I(x) is the beam current distribution value measured along the X direction under the corresponding scanning voltage, and 10 points are measured from left to right in the range of 200mm. It can be seen from the table that the scanning voltage waveform generally passes through 2-3 After one calibration, the horizontal uniformity can reach ±0.5%.

[0050] Vertical uniformity correction data, the test data is shown in Table 2 below:

[0051] Table 2: Unit: 10 14 Particle count / cm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com