Underwater vacuum prepressing reinforcement soft base technique method

A vacuum and soft foundation technology, applied in infrastructure engineering, soil protection, construction, etc., can solve problems such as heavy workload, environmental pollution, and long construction period, and achieve short construction period, broad application prospects, and accelerated construction progress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

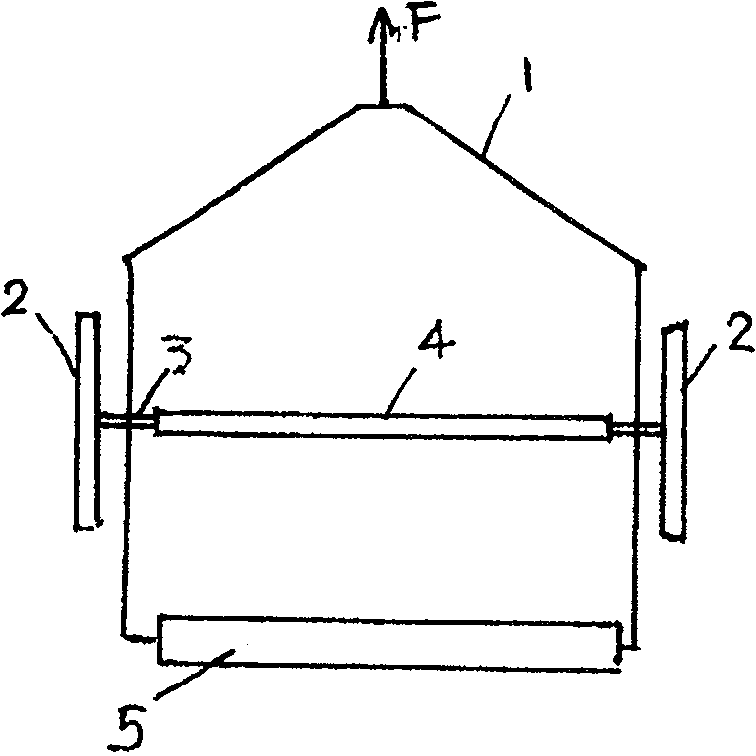

Embodiment Construction

[0096] (1) The innovation of underwater vacuum preloading technology after repeated tests and in-depth research

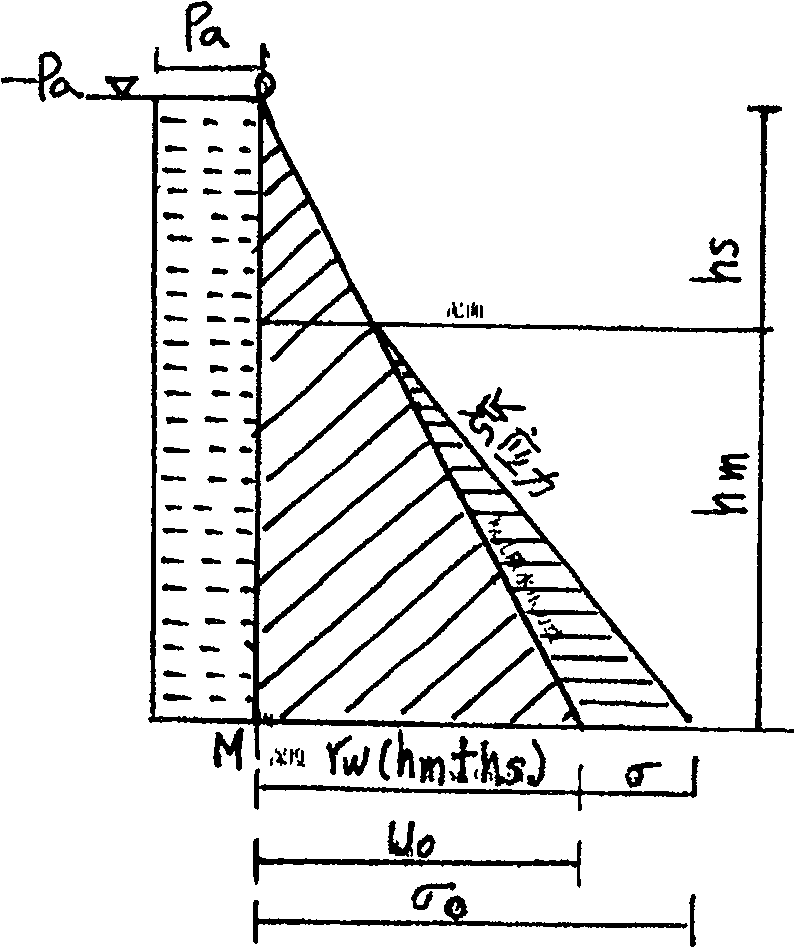

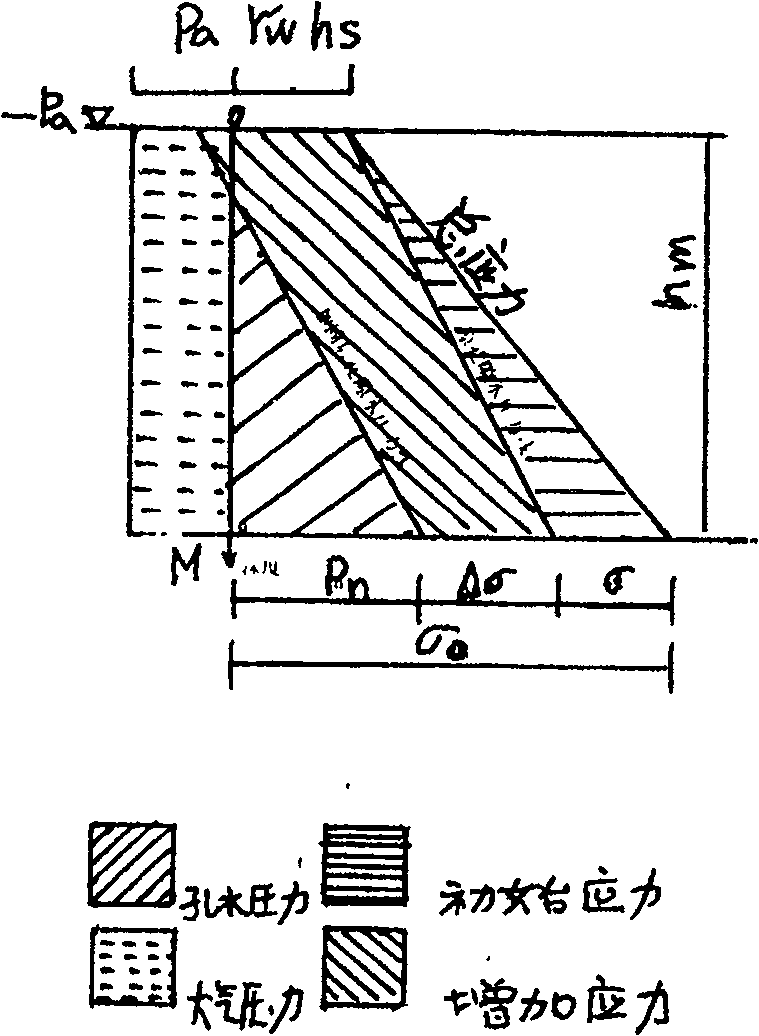

[0097] 1. Reinforcement mechanism of underwater vacuum preloading technology

[0098] Underwater vacuum preloading still belongs to drainage consolidation method in essence. The mechanism of the drainage consolidation method is to set up the drainage system, improve the drainage boundary conditions, shorten the drainage path, and accelerate the drainage. Under the action of the pressurized system, the pore water is discharged, the pore water pressure is reduced and converted into an increase in effective stress, and the soil is consolidated. , to eliminate most of the settlement and improve the compactness and strength, and after the load is unloaded, although there will be a slight rebound, most of the compression deformation is irreversible plastic deformation, and the soil is in an over-compacted state compared to before reinforcement, so that it can be Effecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com