Continuous production of fatty poly-ester carbonate polyhydric alcohol

A polycarbonate and aliphatic technology, applied in the field of polyol production technology, can solve the high production cost of aliphatic polycarbonate polyol, affect the large-scale industrial production and application of resin, increase energy consumption and investment cost of mechanical stirring and other problems, to achieve the effect of simple structure, easy sealing, and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

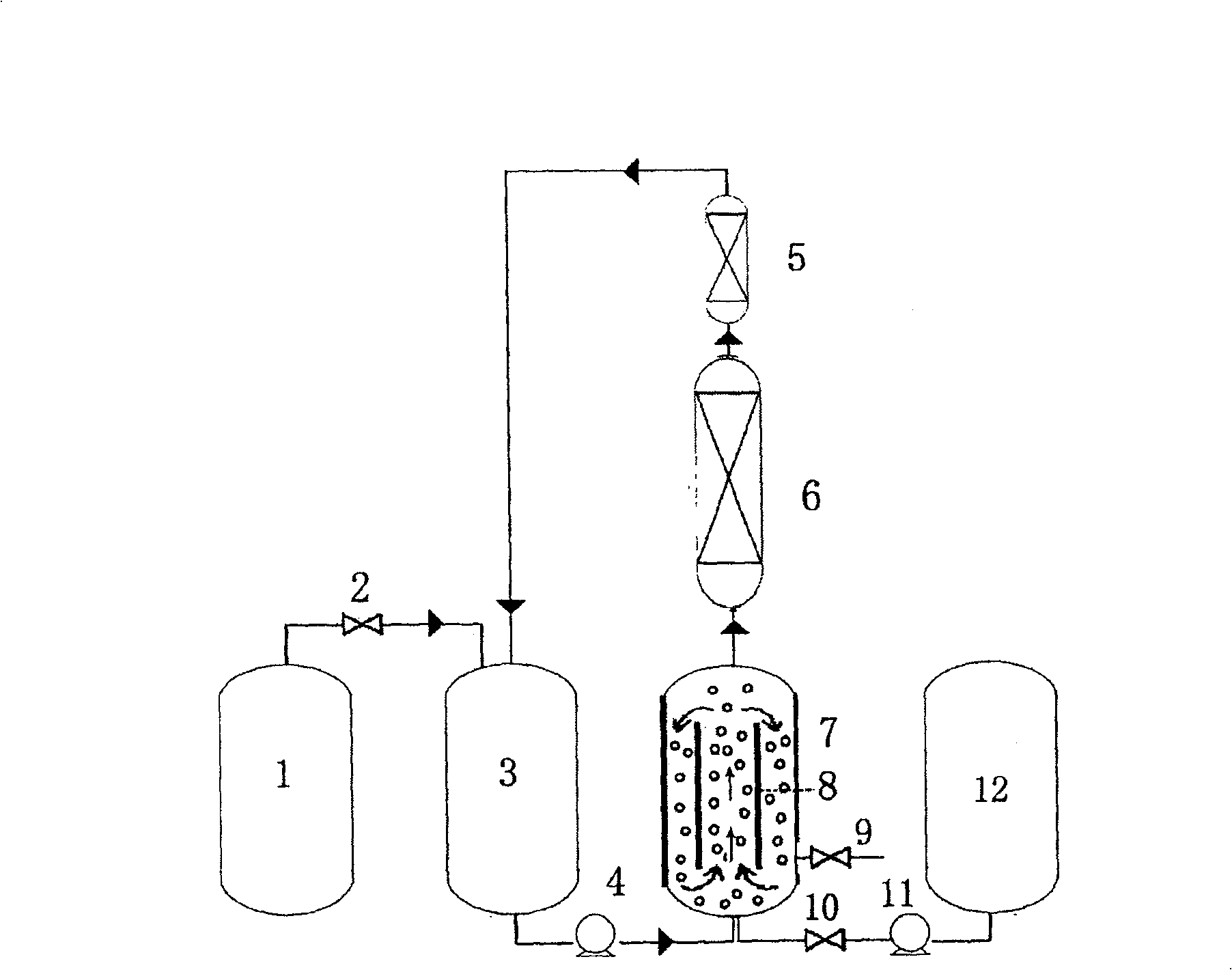

[0016] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS Taking the circulation reactor of a single draft tube as an example, the process of the present invention is further described: the diameter of the outer tube of the loop reactor used is 0.2 meters, the height of the reactor is 2 meters, and the diameter of the inner draft tube is 0.14 meters. The cylinder is 1.4 meters high. The mixing tank is a 10L reaction tank with a stirring device.

[0017] The reaction is polymerized using a solvent-free system. 8 L of the catalyst prepared according to CN 1044663A according to 1.6:3.4:100, fully dried polyether polyol (moisture content 300ppm) with a molecular weight of 300 and an average functionality of 3, epoxy Add propane, etc. into the mixing tank, turn on the stirring device, and fully mix.

[0018] Then add 40kg of the same catalyst, molecular weight modifier and propylene oxide in the same proportion into the loop reactor, feed carbon dioxide to raise the pressure of car...

Embodiment 2

[0021] Using the polymerization device described in Example 1, 8 L of the catalyst prepared according to CN 1044663A according to 1.6: 4.8: 30: 100, the polyether polyol (moisture content) with a molecular weight of 300 and an average functionality of 3 after fully drying 300ppm), toluene, propylene oxide, etc. were added into the mixing tank, and the stirring device was turned on to fully mix.

[0022] Then add 40kg of catalyst, molecular weight regulator and propylene oxide in the same proportion into the loop reactor, introduce carbon dioxide to raise the pressure of carbon dioxide in the system to 4Mpa, start the carbon dioxide compressor, and circulate the material in the system. The heat exchange tube keeps the reaction mass temperature at 60°C. When the solid content of the system reaches 35%, open the high-pressure metering pump, start to feed at a rate of 5 l / min, and open the discharge port at the same time to discharge at the same rate, while keeping the carbon diox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com