Process for improving product quality and yield of propanediol and glycol

A product quality, ethylene glycol technology, applied in the production of bulk chemicals, separation/purification of hydroxyl compounds, preparation of organic carbonates, etc., can solve the problems of poor quality and low yield, and achieve improved quality and simple production process , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

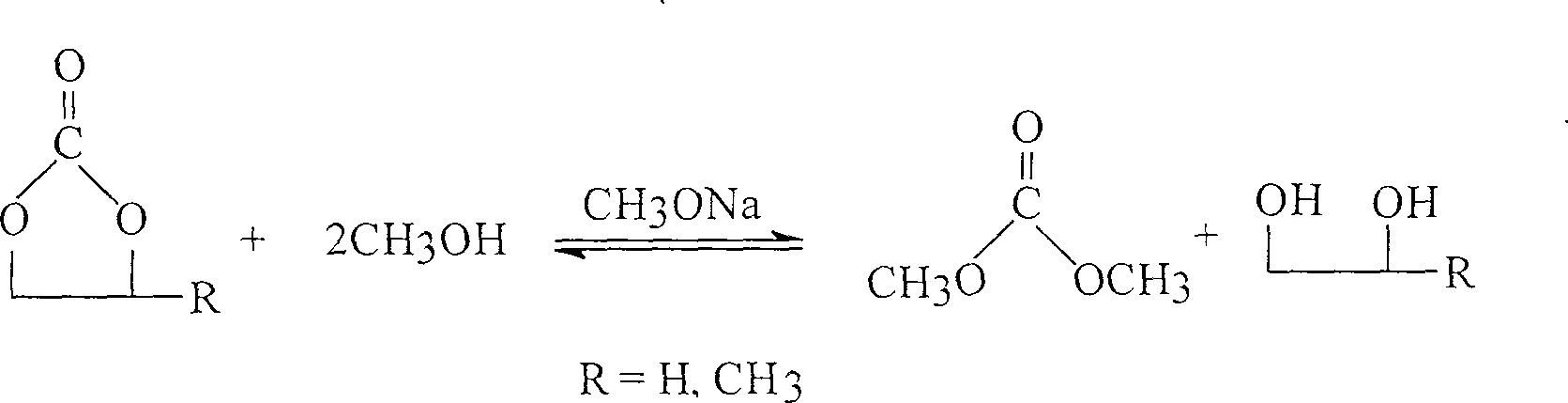

Method used

Image

Examples

Embodiment 1

[0010] 1.293 tons of propylene carbonate, after reacting in the reactive distillation column, after the dimethyl carbonate product generated by the azeotropic method is taken away, 1.000 tons of mother liquor is obtained at the bottom of the column, wherein the methanol content is 1.30%, and the propylene carbonate content 0.30%, sodium methoxide content 2.00%, propylene glycol content 96.40%. Heat the mother liquor to 60°C-70°C, add 100 kg of deionized water and mix well. Pass through 1.5 kilograms of carbon dioxide, filter after reacting for 20 minutes. The filtrate was rectified under reduced pressure to obtain 852 kilograms of propylene glycol products, 100 kilograms of front cuts (containing 92% of propylene glycol), and 90 kilograms of propylene glycol products were obtained through circular vacuum rectification. The total yield of propylene glycol is 97.72%. Propylene glycol product quality analysis test results are as follows: propylene glycol content 99.82%, moistur...

Embodiment 2

[0011] In the reactive distillation tower still, use the same reactive distillation method as in Example 1 to obtain 1.000 tons of mother liquor with the same components as in Example 1 from 1.293 tons of propylene carbonate. Heat the mother liquor to 60°C-70°C, add 50 kg of deionized water and mix well. Feed 1.5 kilograms of carbon dioxide, filter after reacting for 20 minutes, obtain 835 kilograms of propylene glycol products by rectification under reduced pressure of the filtrate, 100 kilograms of front cuts (containing propylene glycol 90.6%), and 88.63 kilograms of propylene glycol products are obtained again through circular rectification under vacuum. The total yield of propylene glycol is 92.54%. Propylene glycol product quality analysis test results are as follows: propylene glycol content 99.80%, moisture 0.05%, chromaticity (platinum-cobalt colorimetric)<10#, heat stability test: 48 hours under 150 ℃, chromaticity (platinum-cobalt colorimetric) <30#.

Embodiment 3

[0013] In the reactive distillation tower still, use the same reactive distillation method as in Example 1 to obtain 1.000 tons of mother liquor with the same components as in Example 1 from 1.293 tons of propylene carbonate. Heat the mother liquor to 60°C-70°C, add 80 kg of deionized water and mix well. Feed 1.5 grams of carbon dioxide, filter after 20 minutes, and rectify the filtrate under reduced pressure to obtain 848 grams of propylene glycol, 100 grams of the front fraction (containing 92% of propylene glycol), and circulate the rectified under reduced pressure to obtain 90 kilograms of propylene glycol products again. EG yield was 97.00%. Propylene glycol product quality analysis test result is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com