Enhancement ultra-high molecular weight polyethylene wound pipe and manufacture method therefor

A technology of ultra-high molecular weight and polyethylene, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems of high longitudinal tensile strength, low hoop stress intensity, and large hoop stress of pipes, and achieve good performance Effects of flame retardancy and antistatic ability, high impact resistance, and improved ring stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

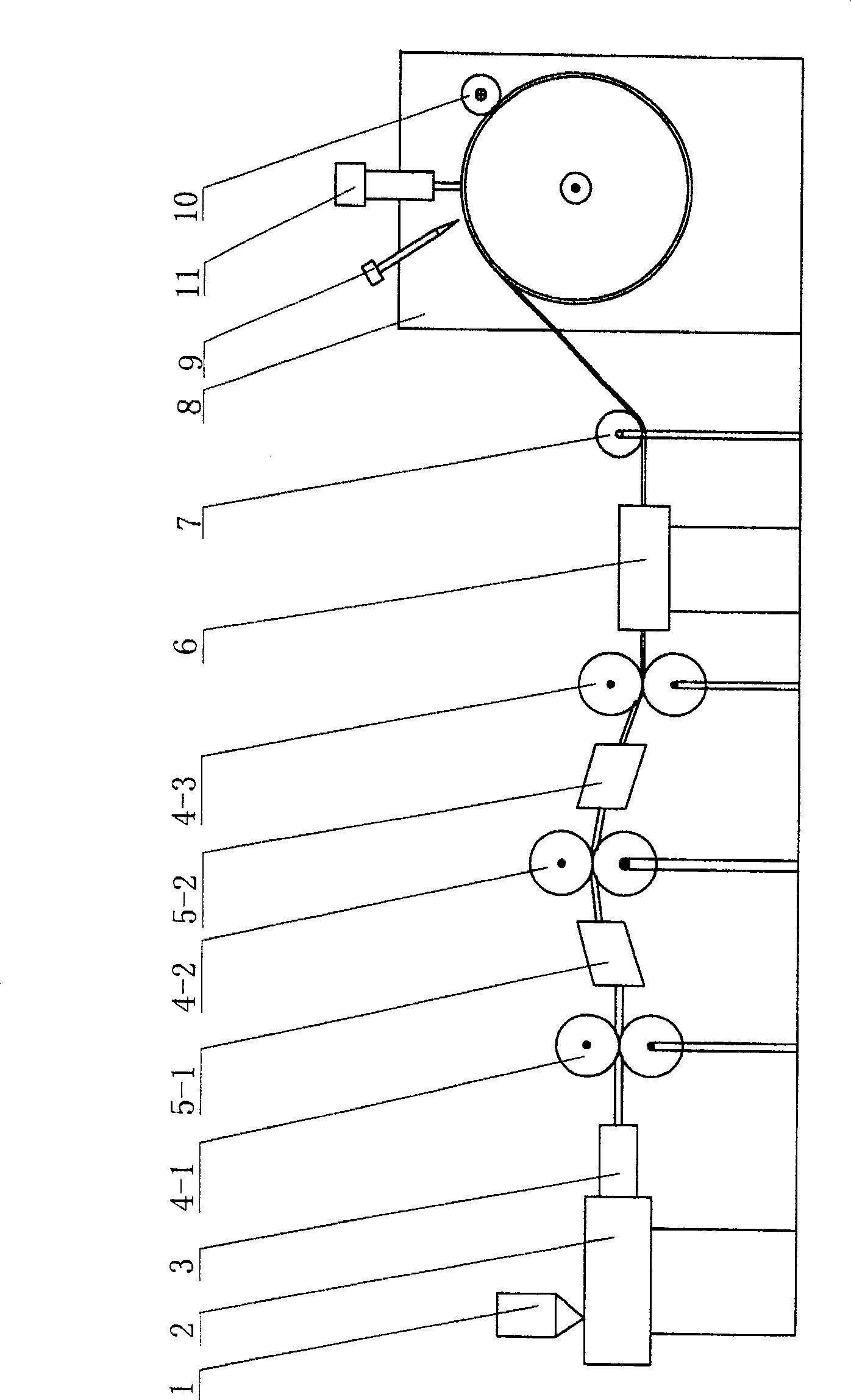

Method used

Image

Examples

Embodiment 1

[0101] Example 1 Fabrication of an ultra-high molecular weight polyethylene winding pipe added with reinforcing materials, flame retardant materials and antistatic materials

[0102] Weight ratio:

[0103] Plastic substrate: reinforcement material: flame retardant material: antistatic material = 1: 0.2: 0.2: 0.3;

[0104] Dosage: plastic substrate 100kg;

[0105] Reinforcement glass fiber 20kg;

[0106] Flame retardant material decabromodiphenyl ether 12kg;

[0108] Antistatic material Conductive carbon black 30kg; raw materials are commercially available industrial products.

[0109] (Note: The winding material is an ultra-high molecular weight polyethylene plastic substrate with a molecular weight ≥ 1.5 million; the welding material is a high-density polyethylene

[0110] Ethylene; the same below. )

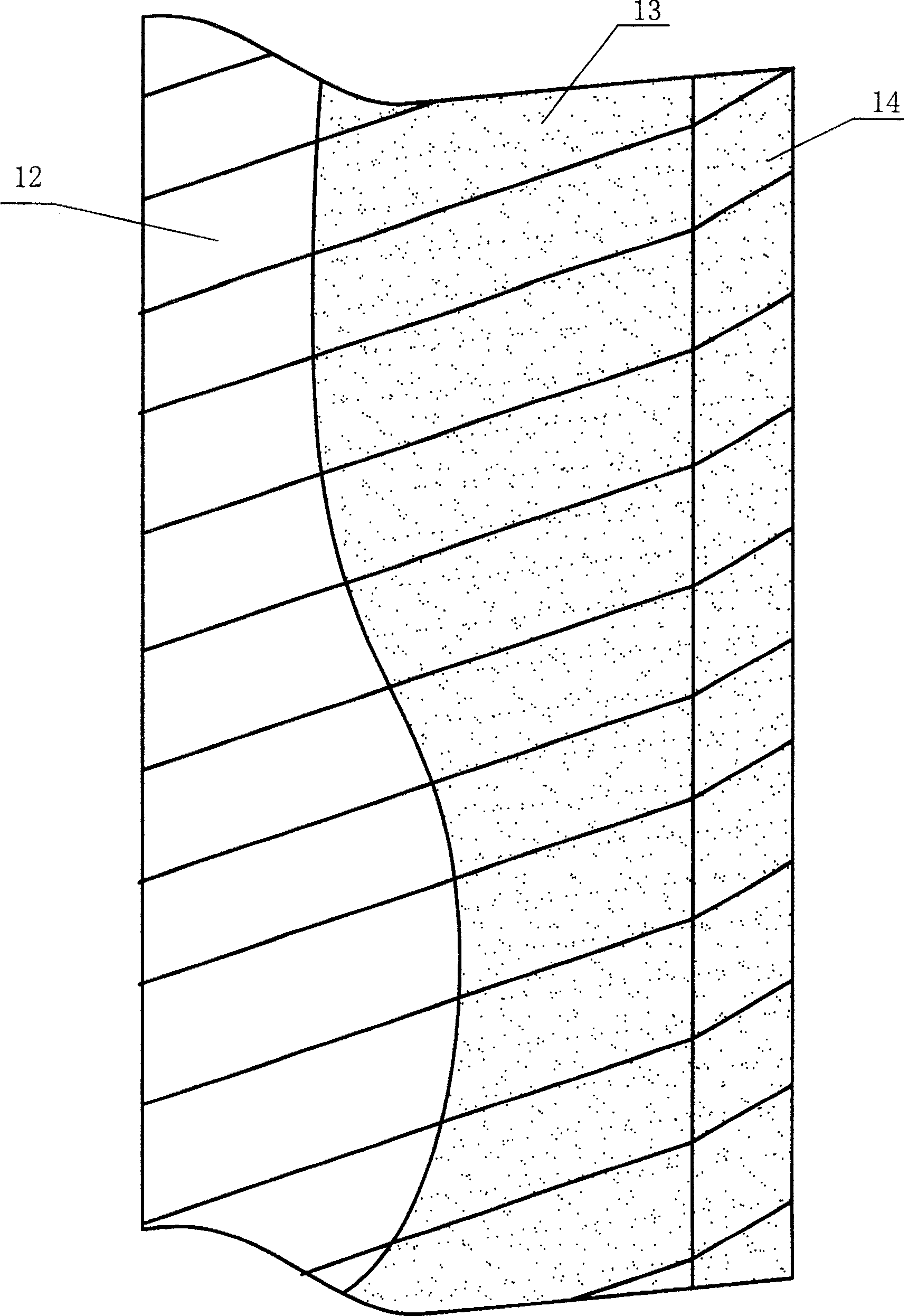

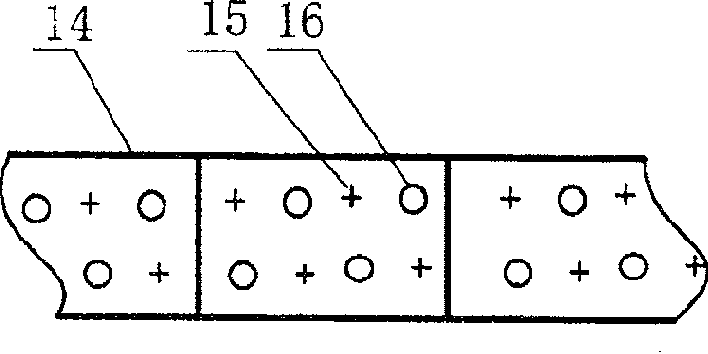

[0111] One method is: the reinforced ultra-high molecular weight polyethylene winding pipe is wound by multi-layer solid ultra-high molec...

Embodiment 2

[0135] Embodiment 2 makes the ultra-high molecular weight polyethylene pipe that adds reinforcing material

[0136] Weight ratio:

[0137] Plastic substrate: reinforcing material = 1:0.8;

[0138] Dosage: plastic substrate 100kg;

[0139] Reinforcement material glass fiber 80kg; raw materials are commercially available industrial products.

[0140] While winding the winding material (plastic solid profile compounded with reinforcing material) by the winding machine, the molten welding material is applied to the adjacent side of the winding winding material, and pressure is applied to melt and bond it into one; the winding The diameter is 2000mm; finally, the wound pipe wall is rolled by a rotary rolling device to make the pipe wall regular and smooth.

[0141] Using the above ratio to make a spiral pipe with a diameter of 2000mm and a standard size ratio (SDR) of 34.3, the results of its working pressure compared with the pure UHMW-PE solid wall pipe are as follows:

[014...

Embodiment 3

[0146] Embodiment 3 Manufacture the ultra-high molecular weight polyethylene pipe adding reinforcing material, wear-resistant material and antistatic material

[0147] Weight ratio:

[0148] Plastic substrate: reinforcement material: wear-resistant material: antistatic material = 1: 0.6: 0.2: 0.1;

[0149] Dosage: plastic substrate 100kg;

[0150] Reinforcement material carbon / graphite fiber 60kg;

[0151] Wear-resistant material silica powder (or silica sand or glass beads) 20kg;

[0152] Antistatic material Conductive carbon black 10kg; raw materials are commercially available industrial products.

[0153] Using the above ratio to make a spiral pipe with a diameter of 2000mm and a standard size ratio (SDR) of 26.0, the results of its working pressure compared with the pure UHMW-PE solid wall pipe are as follows:

[0154]

[0155] Note: The wear rate of mortar is implemented according to the regulations of QB / T 2668-2004, and the wear rate of mortar of the prese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com