Magnetic fluid grinding device for ceramic ball surface grinding

A surface grinding and grinding device technology, which is applied in the direction of grinding devices, grinding machine tools, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

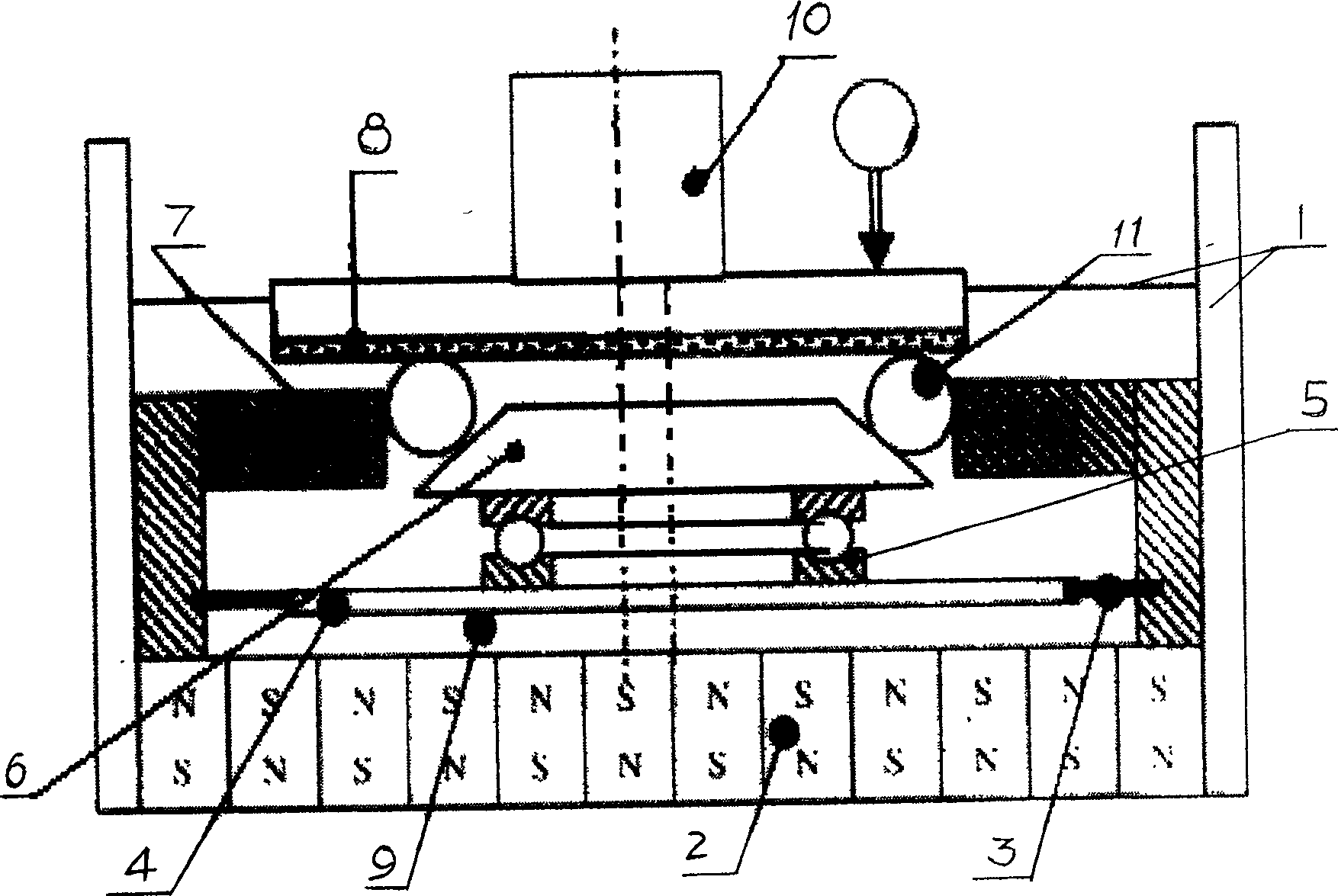

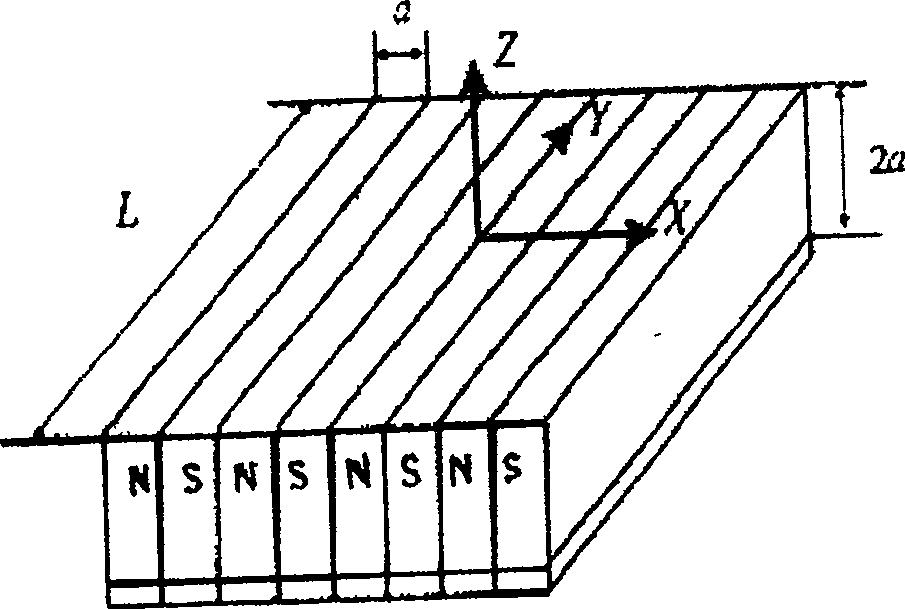

[0010] The magnetic fluid grinding device used for ceramic ball surface grinding includes a casing 1, a magnet assembly 2 composed of permanent magnets arranged in crossed N and S poles is arranged at the bottom of the casing, and the upper part of the magnet assembly 2 is provided with an elastic coupling 3 The floating plate 4 connected and fixed with the inner wall of the casing, the bearing 5 (thrust bearing) is fixed on the floating plate 4, the circular table-shaped tray 6 is fixed on the upper part of the bearing, and the guide ring 7 is also fixed in the casing, on the top of the casing (i.e. Conical tray and the upper part of the guide ring) are provided with a driven grinding wheel 8, the lower surface of the driven grinding wheel 8, the inner surface of the guide ring 7 and the conical surface of the conical tray 6 form a space for placing ceramic balls, and the inner cavity of the casing is filled. ferrofluid. The magnet assembly 2 consists of twelve permanent magn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com