Method for preparing silver copper oxide electric contacting material

An electrical contact material, copper oxide technology, applied in the field of metal matrix composite material science, can solve the problems of difficult processing, no requirement for the use of high-performance low-voltage electrical appliances, etc., achieve easy control of process flow, realize mass production, increase physical The effect of bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

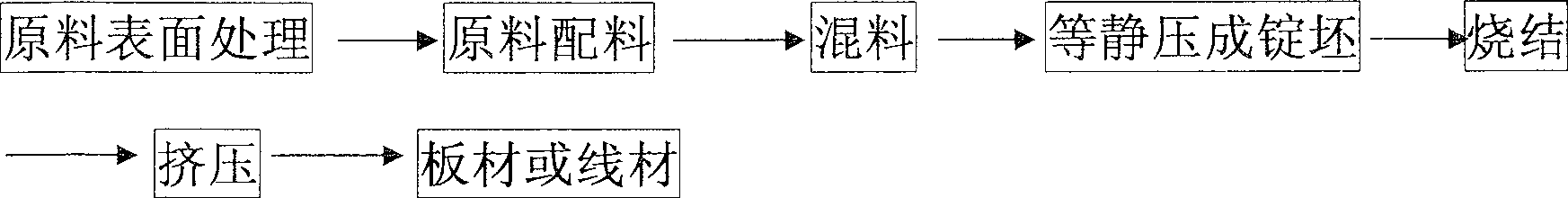

Method used

Image

Examples

Embodiment 1

[0025] Embodiment one: by 10% copper oxide powder (percentage by weight), 90% silver powder (percentage by weight) as raw material, surface treatment at 180 DEG C for 5 hours, after 12 hours of powder mixing, in 250MPa isostatic pressing It is pressed into an ingot under pressure, sintered at 700°C for 8 hours, and then extruded into a sheet at a temperature of 750°C. After surface treatment and silver coating, the sheet is rolled, punched, and processed into a sheet contact .

Embodiment 2

[0026] Embodiment two: by 15% copper oxide powder (percentage by weight), 84.5% silver powder (percentage by weight) as raw material, and add 0.5% bismuth oxide, surface treatment at 250 ℃ for 8 hours, through 15 hours of powder mixing Finally, it is pressed into an ingot under an isostatic pressure of 270MPa, sintered at 750°C for 10 hours, and then extruded into a plate at a temperature of 750°C. After surface treatment, the plate is rolled and punched into type, processed into chip contacts.

Embodiment 3

[0027] Embodiment three: by 15% copper oxide powder (percentage by weight), 84.7% silver powder (percentage by weight) as raw material, and add 0.3% nickel oxide, surface treatment 8 hours at 250 ℃, through 15 hours of powder mixing Finally, it is pressed into an ingot under an isostatic pressure of 270MPa, sintered at 750°C for 10 hours, and then extruded into a plate at a temperature of 750°C. After surface treatment, the plate is rolled and punched into type, processed into chip contacts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com