Hollow fiber blend membrane and method for manufacturing same

A technology of blending membranes and fibers, applied in the field of materials, can solve the problems of membrane flux attenuation, increase of transmembrane pressure difference, poor acid and alkali resistance, etc., and achieve improved hydrophilic durability, improved properties, and increased selectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

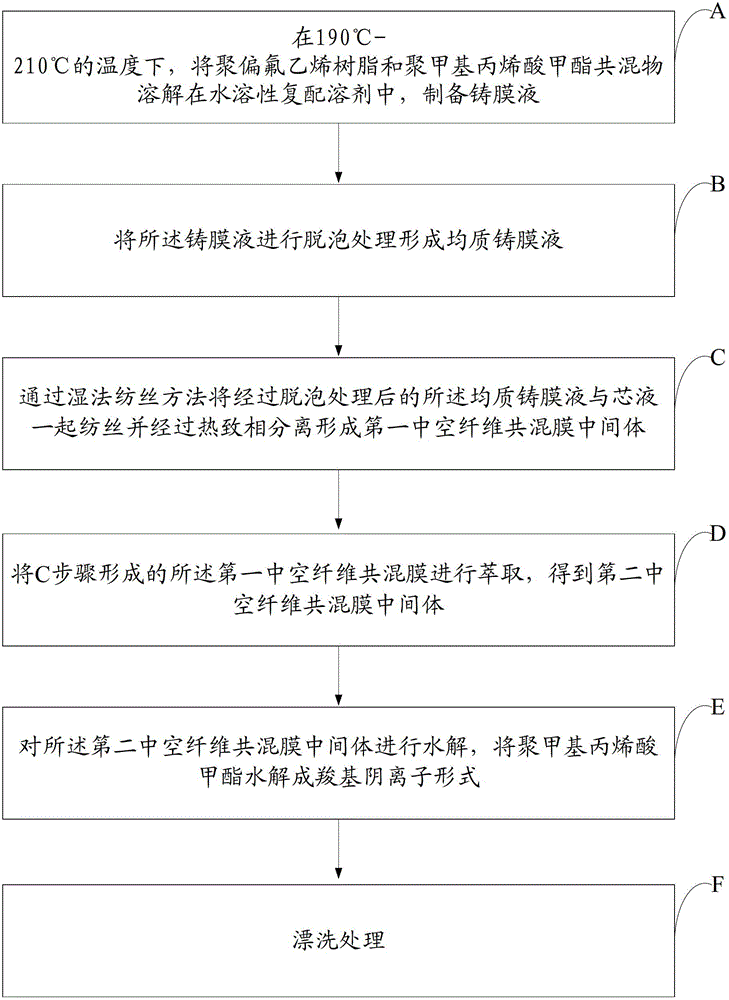

[0063] The present invention also provides a method for preparing the above-mentioned hollow fiber blend membrane, comprising the following steps:

[0064] A. Dissolving the polyvinylidene fluoride resin and polymethyl methacrylate blend in a water-soluble compound solvent at a temperature of 190°C-210°C to prepare a casting solution;

[0065] B. carrying out degassing treatment to the casting solution to form a homogeneous casting solution;

[0066] C. Spinning the homogeneous casting solution and the core solution after the degassing treatment and undergoing thermal phase separation to form the first hollow fiber blended membrane intermediate;

[0067] D. Extracting the first hollow fiber blended membrane intermediate formed in step C to obtain a second hollow fiber blended membrane intermediate;

[0068] E. Hydrolyzing the second hollow fiber blended membrane intermediate to hydrolyze polymethyl methacrylate into carboxyl anion form.

[0069] Through the method of polymer...

Embodiment 1

[0112] Mix the dried 35wt% powdered polyvinylidene fluoride homopolymer (SOLEF6010, MW=350,000) and 5wt% granular random polymethyl methacrylate (CM205, MW=70,000-80,000) evenly, add to In the stirring tank, then add N-methylpyrrolidone as the first solvent and glycerol compound solvent as the second solvent, wherein the concentration of N-methylpyrrolidone is 22wt%, and the concentration of glycerol is 38wt%.

[0113] The above mixture was stirred for 24 hours at a temperature of 200° C. at a rotational speed of 100 rpm, and vacuum defoamed at a temperature of 200° C. for 8 hours to obtain a homogeneous casting solution.

[0114] Keep the casting liquid at 200°C and pass through a 250-mesh filter before entering the intubation spinneret and spraying out together with the core liquid in the center tube of the nozzle. The core fluid is composed of 40wt% deionized water, 30wt% N-methylpyrrolidone, and 30wt% glycerol. The ejected casting solution was spun by 25 cm of air, cooled...

Embodiment 2

[0122] Except that in the N-methylpyrrolidone as the first solvent and the glycerol mixed solvent as the second solvent, wherein the concentration of N-methylpyrrolidone is 20wt%, and the concentration of glycerol is 40wt%, the others are the same as in Example 1.

[0123] The performance of the obtained thermotropic hydrophilic polyvinylidene fluoride hollow fiber blend membrane is as follows:

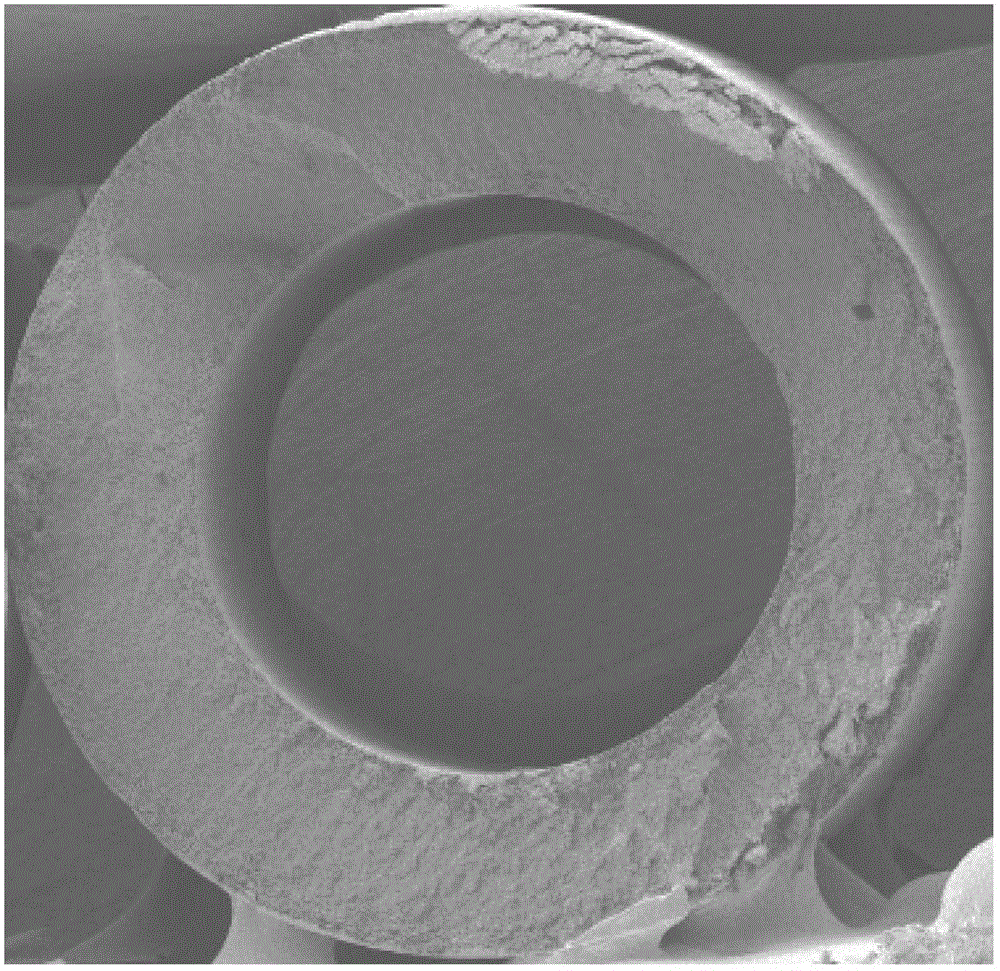

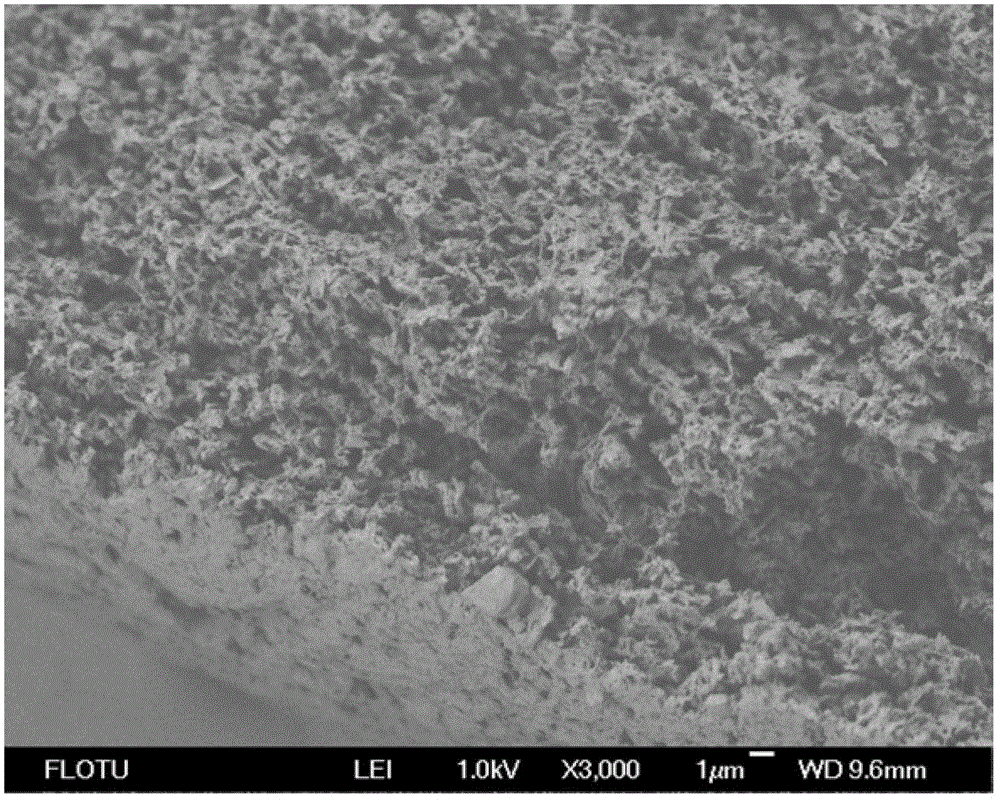

[0124] Among them, the inner and outer diameters of the second hollow fiber blended membrane intermediate are 0.8mm / 1.3mm, the porosity is 68%, the pure water flux is 480L / m2·h·bar·25℃, the average pore diameter is 0.07μm, and the tensile strength Greater than 6.3N / mm2, the elongation rate is 150%, and the compressive strength is greater than 0.6Mpa.

[0125] The inner and outer diameter of the finished hollow fiber blend membrane is 0.8mm / 1.3mm, the porosity is 68%, the pure water flux is 570L / m2·h·bar·25℃, the average pore diameter is 0.07μm, and the tensile strength is greater than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com