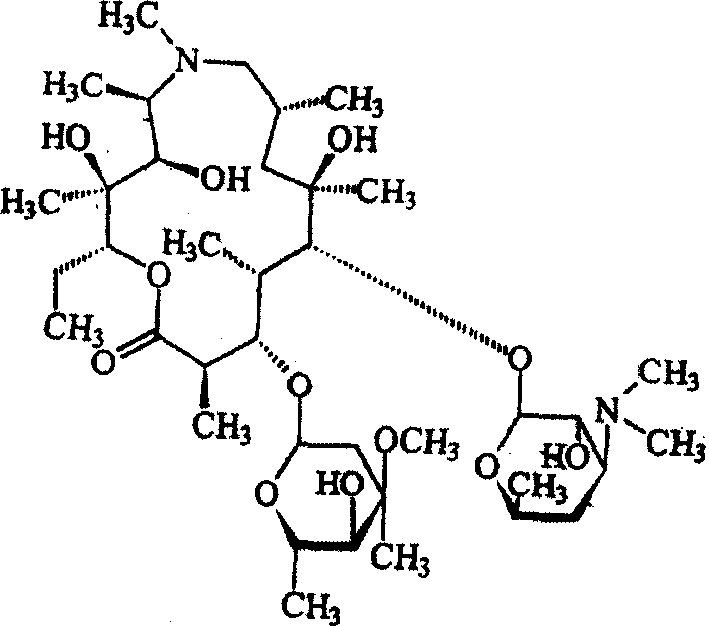

Azithromycin mix suspension grain and method for preparing the same

A technology of suspension granules and azithromycin, which is applied in the field of medicine, can solve the problems of no teaching or suggestion of azithromycin suspension granules, no provision of suspension uniformity and stability of suspension granules, no provision of azithromycin suspension granules, etc. Achieve the effect of improving the problem of moisture absorption, solving the problem of moisture absorption, and good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] 1. Specification: 0.1g

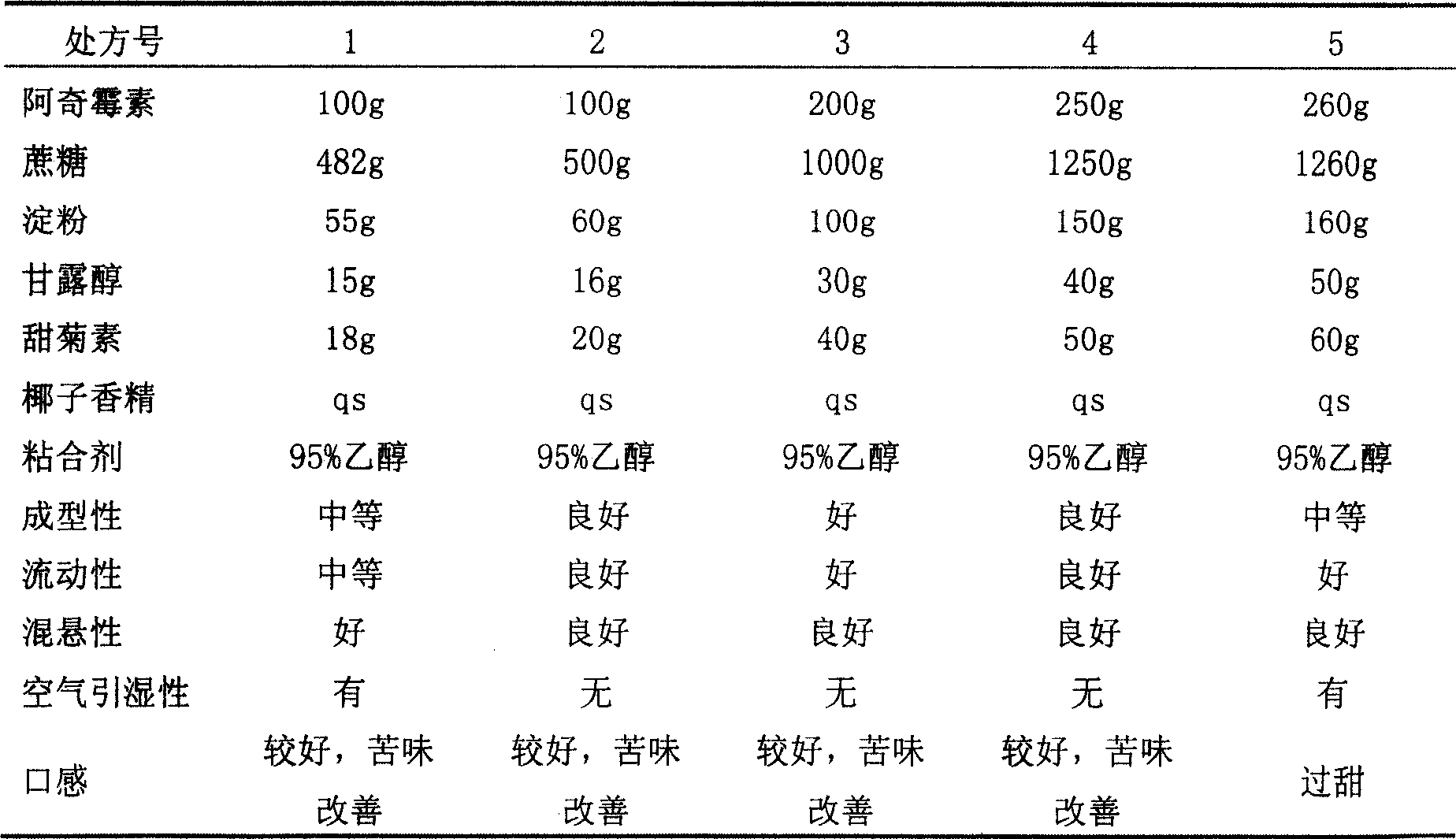

[0075] 2. Prescription:

[0076]

[0077]

[0078] 3. Preparation process:

[0079] (1) Take the raw materials and auxiliary materials of the prescription amount, pulverize azithromycin, sucrose and mannitol respectively, pass through a 100 mesh sieve, and pass the starch through a 120 mesh sieve to obtain the original and auxiliary material powders;

[0080] (2) Place the raw and auxiliary material powder obtained in the previous step in a mixer and dry-mix for 10 minutes, add 95% ethanol, and wet-mix for 30 seconds to make a soft material. Granules to obtain wet granules;

[0081] (3) Place the wet granules prepared in the previous step evenly in the fluidized dryer, adjust the air inlet temperature to 60°C, dry for 40 minutes, and the moisture content is 3.5%, then stop the machine, clean the filter bag, and discharge to obtain dry granules ;

[0082] (4) Add the dry granules and coconut essence to a granulator for granulation, pass...

Embodiment 2

[0084] 1. Specification: 0.25g

[0085] 2. Prescription:

[0086]

[0087] 3. Preparation process

[0088] (1) Take the raw materials and auxiliary materials of the prescription amount, pulverize azithromycin, sucrose and mannitol respectively, pass through a 100 mesh sieve, and pass the starch through a 120 mesh sieve to obtain the original and auxiliary material powders;

[0089] (2) Put the raw and auxiliary material powder obtained in the previous step into a mixer, seal and dry mix for 5 minutes, add 95% ethanol, wet mix for 150 seconds to make a soft material, and granulate under the conditions of an ambient temperature of 20°C and a relative humidity of 25%. , to get wet particles;

[0090] (3) Place the wet granules prepared in the previous step evenly in the fluidized dryer, adjust the air inlet temperature to 70°C, dry for 50 minutes, and the moisture content is 4%, then stop the machine, clean the filter bag, and discharge to obtain dry granules ;

[0091] (4...

Embodiment 3

[0093] 1. Prescription:

[0094]

[0095] 2. Preparation process:

[0096] (1) Take the raw materials and auxiliary materials of the prescription amount, pulverize azithromycin, sucrose and mannitol respectively, pass through a 100 mesh sieve, and pass the starch through a 120 mesh sieve to obtain the original and auxiliary material powders;

[0097] (2) Put the raw and auxiliary material powder obtained in the previous step into a mixer, seal and dry mix for 15 minutes, add 95% ethanol, and wet mix for 100 seconds to make a soft material, and granulate to obtain wet granules;

[0098] (3) Place the wet granules prepared in the previous step evenly in the fluidized dryer, adjust the air inlet temperature to 65°C, dry for 45 minutes, and the moisture content is 3.8%, then stop the machine, clean the filter bag, and discharge to obtain dry granules ;

[0099] (4) Add the dry granules and coconut essence to a granulator for granulation, pass through a 20-mesh sieve, and afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com