A method for making CDSEM calibration sample

A manufacturing method and sample technology, applied in the fields of semiconductor/solid-state device manufacturing, electrical components, semiconductor/solid-state device testing/measurement, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

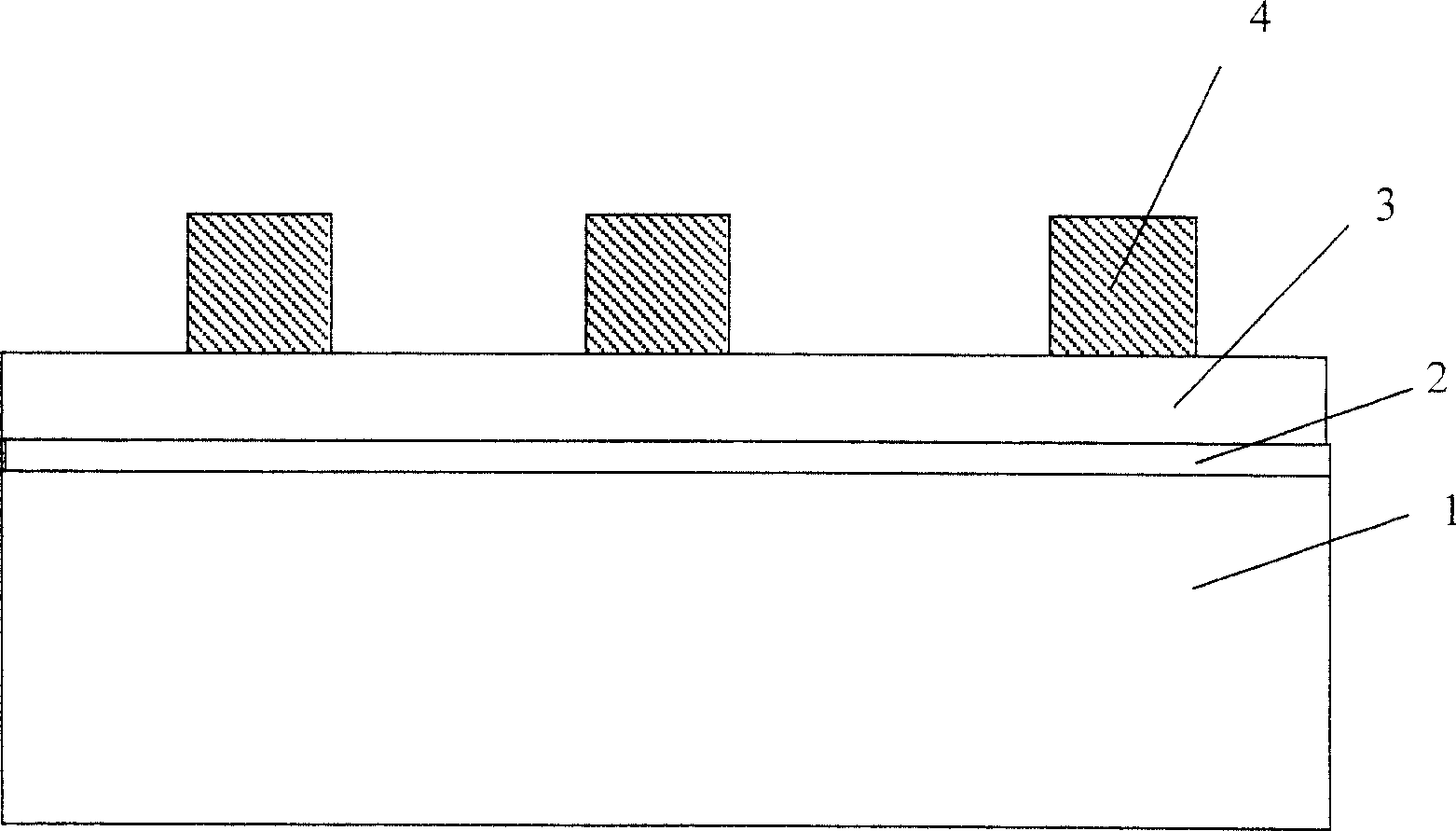

[0033] A kind of equipment of the present invention measures key dimension in semiconductor manufacturing process, as the preparation method of the sample that CDSEM carries out calibration, comprises:

[0034] Fabrication of the polysilicon gate structure and forming a conductive layer on the entire surface of the polysilicon gate structure.

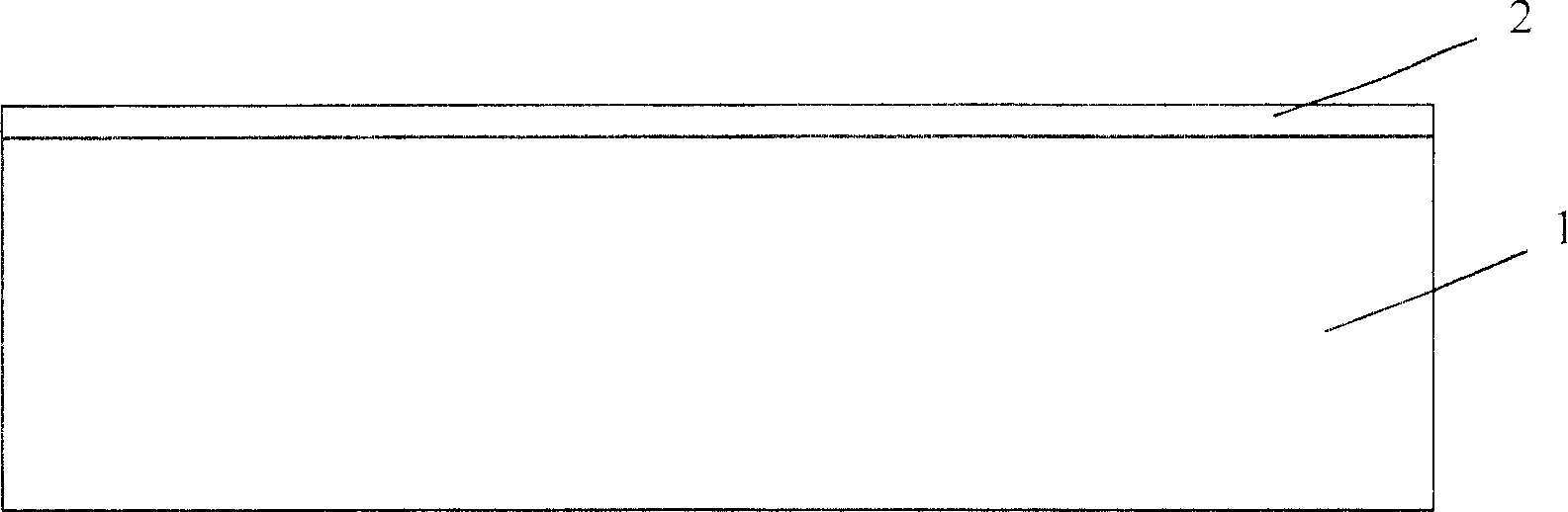

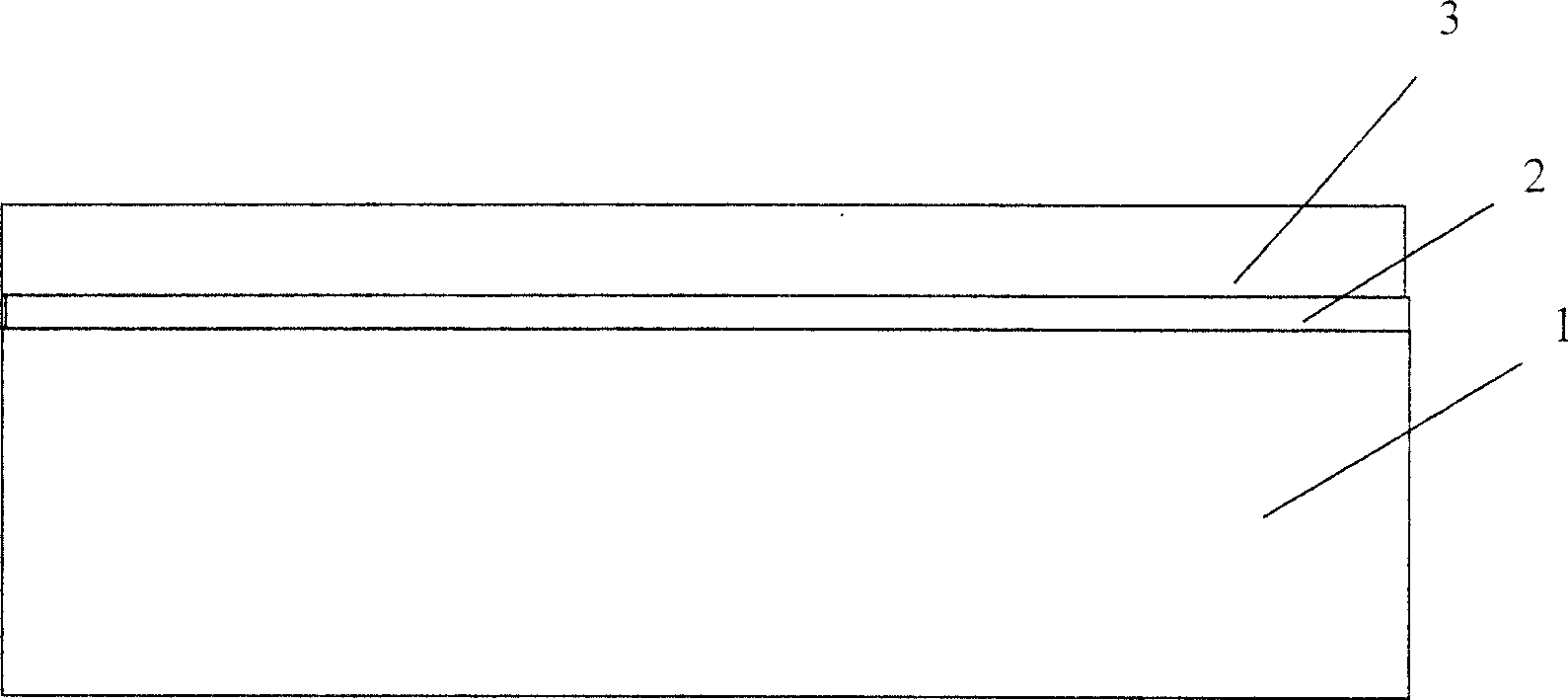

[0035] The polysilicon grid structure of the present invention can be made according to the fabrication method of the conventional polysilicon grid structure, that is, at first pre-cleaning is carried out on the silicon substrate, and sulfuric acid (H 2 SO 4 ), hydrofluoric acid (HF), ammonia + hydrogen peroxide + deionized water (NH 4 OH+H 2 o 2 +DI), hydrochloric acid + hydrogen peroxide + deionized water (HCL+H 2 o 2 +DI) to remove oxides or pollutants on the surface of the wafer; then thermal oxidation and other methods are used to form a pad oxide layer, generally at a temperature of 900-1100°C to form an oxide layer with a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com