Method and apparatus for concrete damage detection based on impedance imaging

A technology for damage detection and detection equipment, which is applied in the direction of material resistance and can solve the problems of large detection workload, inability to realize real-time monitoring, and limited detection depth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

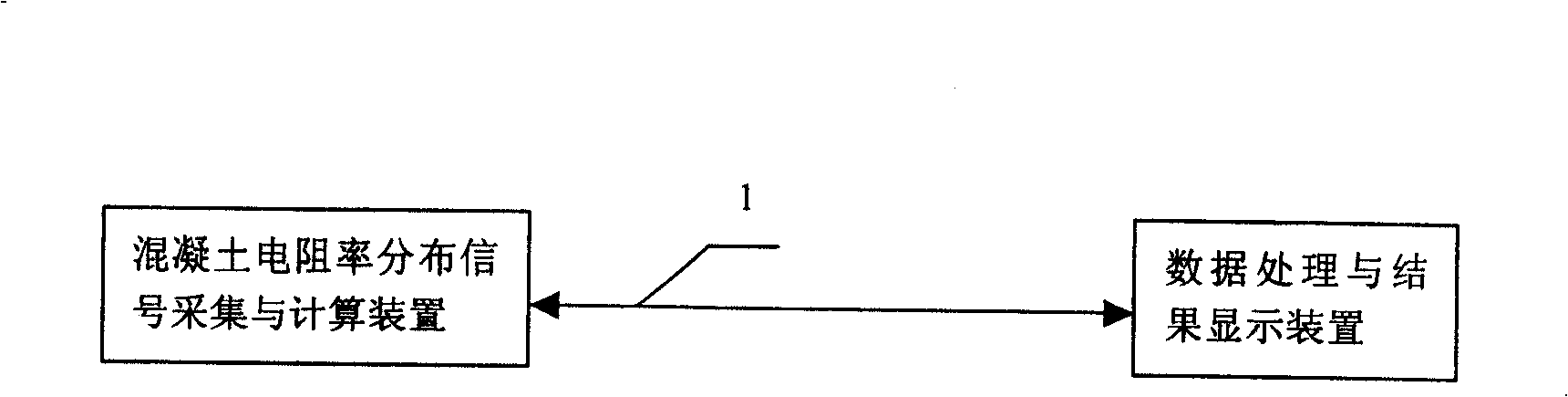

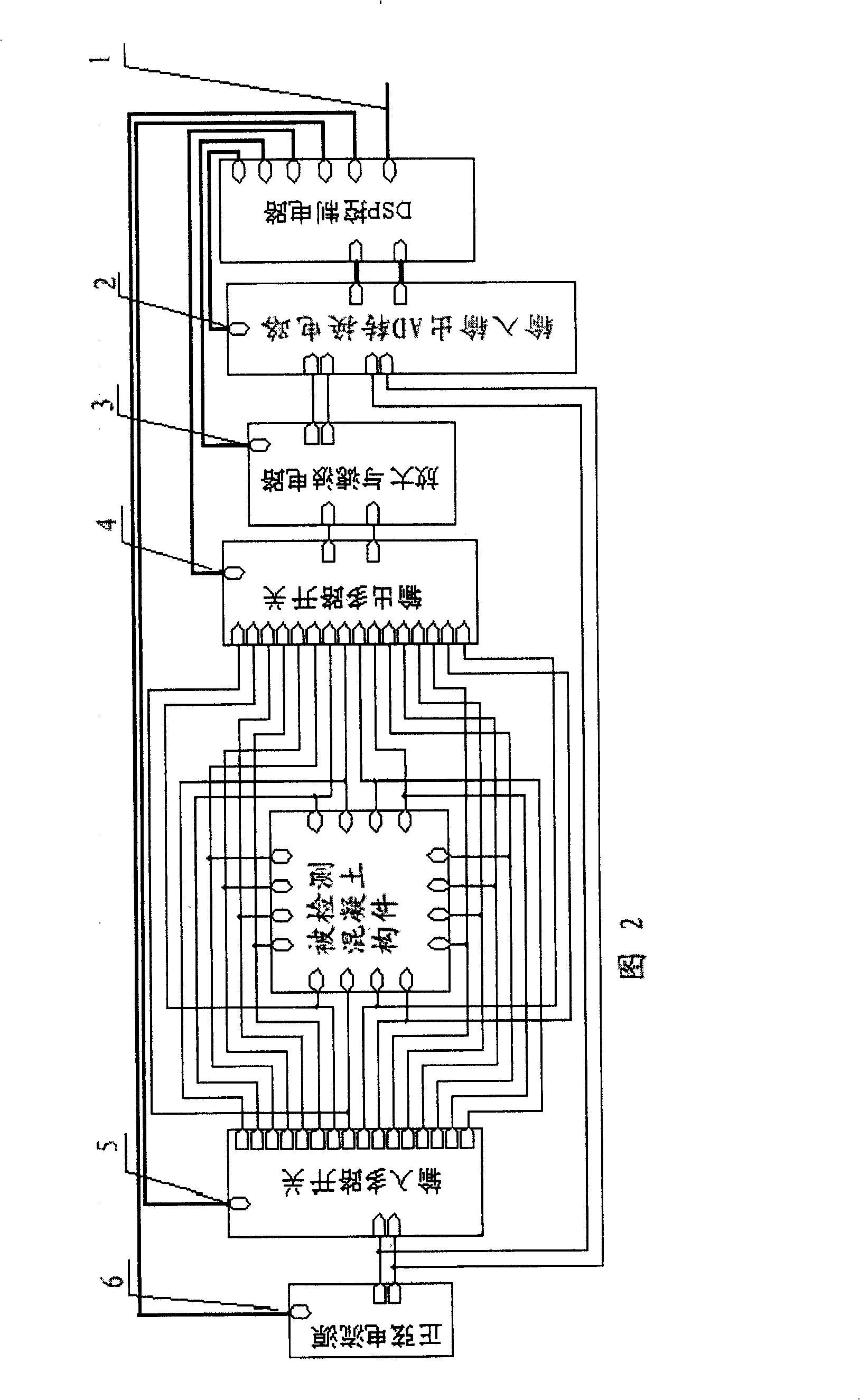

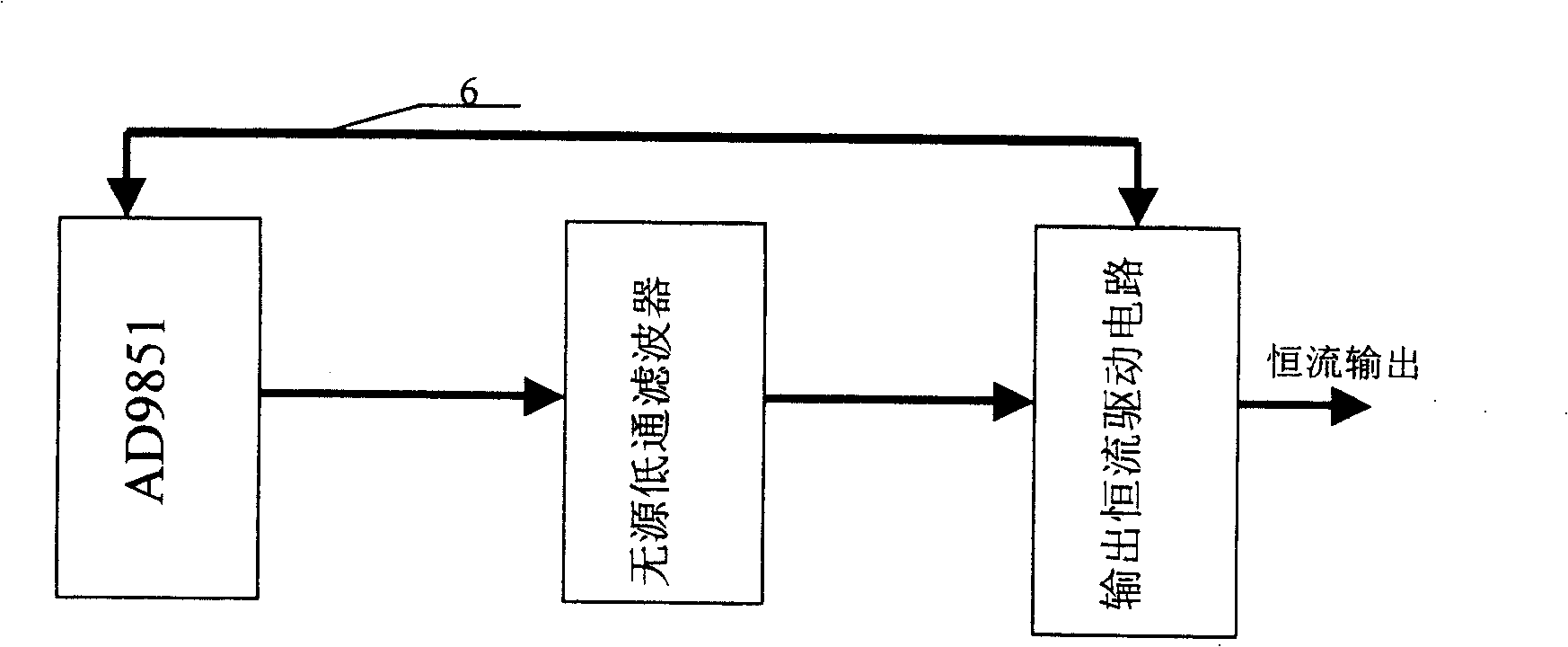

[0085] The structure of the detection equipment described in this embodiment is as follows: figure 1 As shown, it includes a concrete resistivity distribution signal acquisition and calculation device, a data processing and result display device, and the two devices are connected through a communication bus 1 . The data processing and result display device adopts industrial control computer; the structure of the concrete resistivity distribution signal acquisition and calculation device is shown in Figure 2, including sinusoidal current source, input multi-way switch, output multi-way switch, amplification and filter circuit, AD conversion circuit, DSP control circuit.

[0086]As shown in Figure 2, the concrete component to be tested is a square component, and four copper electrodes are evenly distributed on each side of the component, a total of sixteen electrodes. The output end of the sinusoidal current source is connected with the input multi-way switch and the AD convers...

Embodiment 2

[0095] In this embodiment, the damage of a square concrete member is detected, and the concrete member is set as Figure 14 Shown crack, with the detection equipment described in embodiment 1, step is as follows:

[0096] (1) Set 16 red copper electrodes on the concrete component to be tested, and 4 electrodes are evenly distributed on each side of the concrete component, as shown in Figure 2.

[0097] (2) Connect the excitation input port of each electrode provided on the concrete component to be detected with the input multiplex switch of the detection equipment, and connect the response output port of each electrode provided on the concrete component to be detected with the output multiplex switch of the detection equipment , the connection method is shown in Figure 2.

[0098] (3) To operate the detection equipment, the industrial control computer sends control commands to the concrete resistivity distribution signal acquisition and calculation device, and the sinusoidal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com