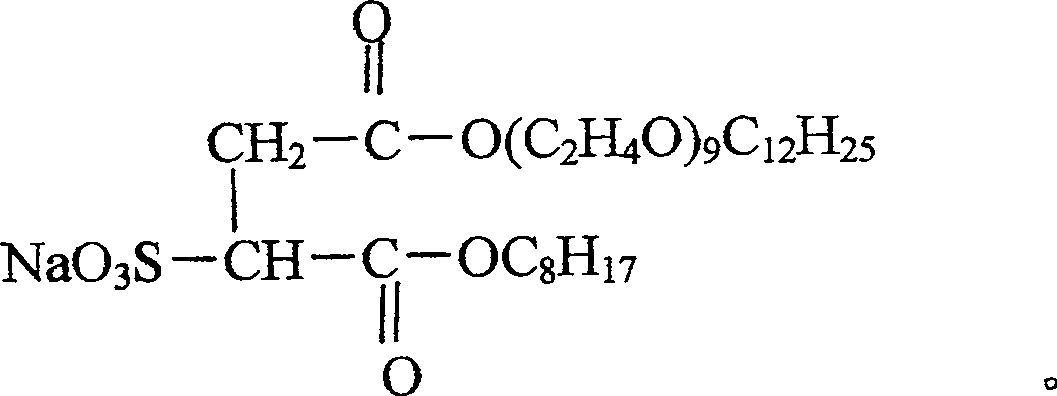

Sodium polyoxyethylene fatty alcohol ether (9) octyl sulfosuccinate and its preparing process

A technology of alcohol polyoxyethylene ether and sulfosuccinic acid, which is applied in chemical instruments and methods, dissolution, chemical/physical processes, etc., can solve the problems of complicated procedures and unsatisfactory product performance, and achieves compact process and low cost. Equipment requirements, the effect of reducing the consumption of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

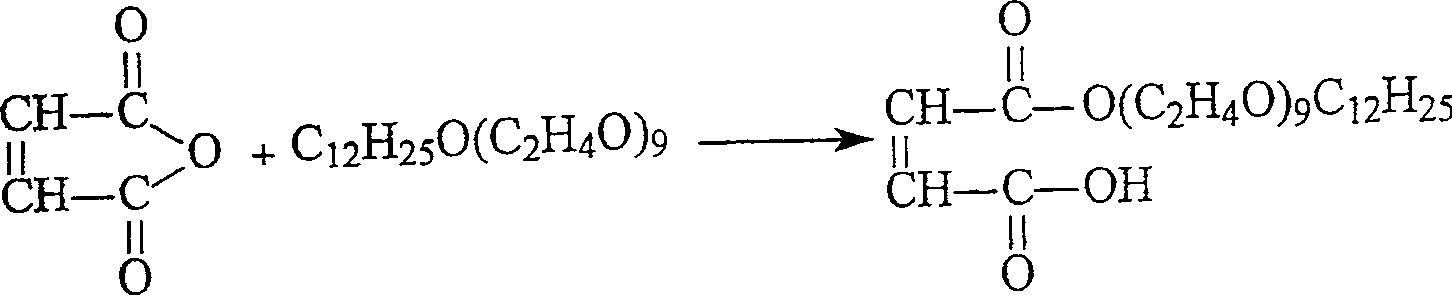

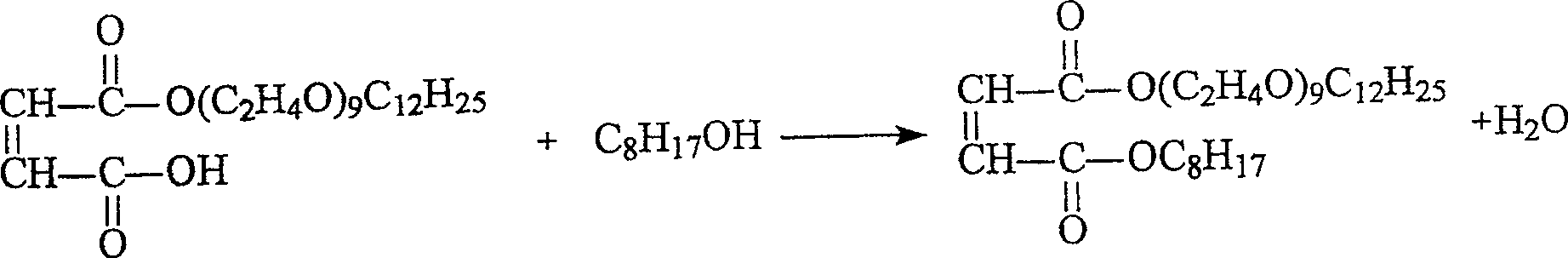

[0017] In a four-necked flask equipped with a stirrer, a thermometer and a reflux condenser, add the fatty alcohol after the water treatment in sequence according to the mass ratio (molar ratio) of fatty alcohol polyoxyethylene ether (9):maleic anhydride=1.00:1.20 Add polyoxyethylene ether (9), maleic anhydride, and add an alkylsulfonic acid catalyst accounting for 1% of the mass of maleic anhydride, feed nitrogen, stir and heat up to a temperature of 140°C within 10 to 30 minutes; keep this temperature and time it, the holding time 120min, connect the water separator on the same reaction device, and add octanol by the mass ratio (molar ratio) of octanol:maleic anhydride=4.0:1.0 to carry out double esterification reaction, by the method for above-mentioned monoesterification reaction It is heated to 240°C and timed, heat-preserved and dehydrated, the heat-preserved time is 330min, cooled, neutralized, cooled to a temperature of 20-60°C, and neutralized to a pH value of 7±0.5; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com