High voltage N-shape metal oxide semiconductor tube and its preparing method

A technology of semiconductor tubes and oxides, which is applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of insufficient comprehensiveness, without considering the thickness of the oxide layer, field plate, etc., and achieves low manufacturing cost and conduction. The effect of resistance reduction and breakdown voltage improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

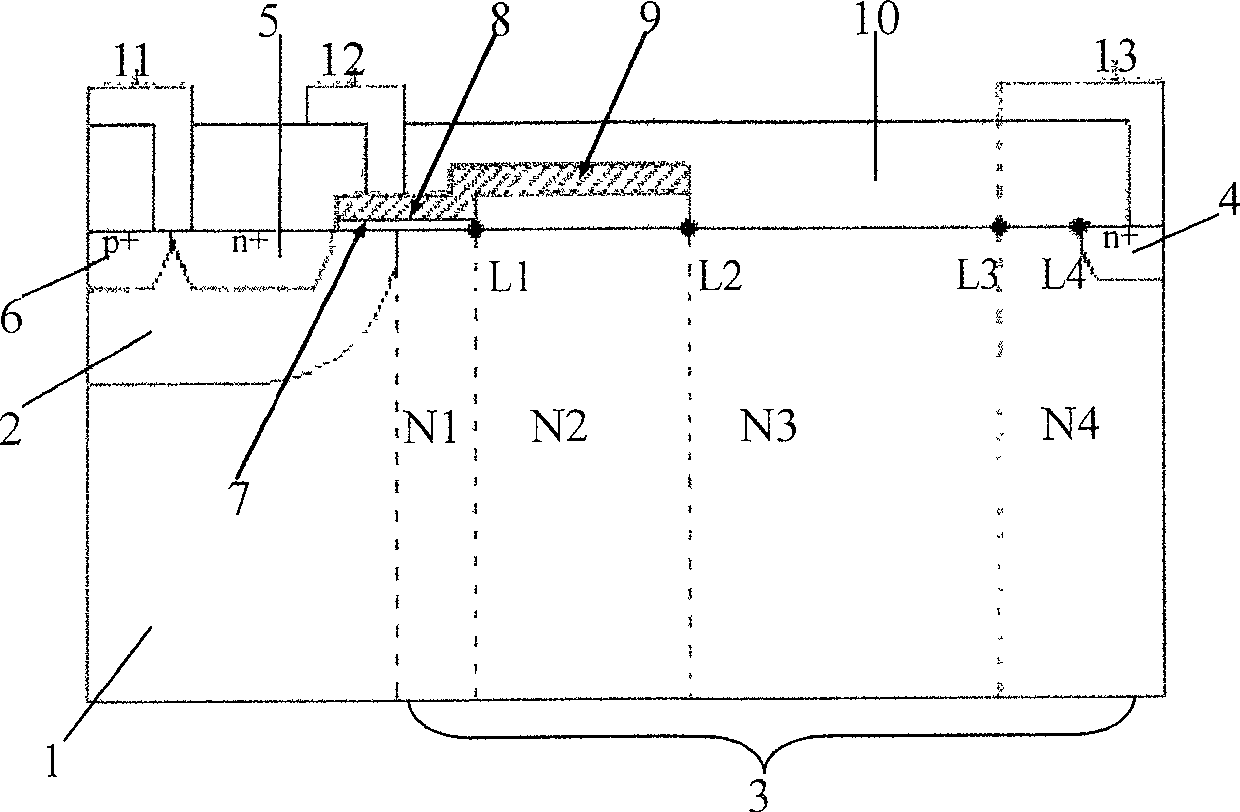

[0015] refer to figure 1 , a linearly doped high-voltage N-type metal oxide semiconductor tube, comprising an N-type substrate 1, a P-type well 2 and an N-type drift region 3 are arranged on the N-type substrate 1, and a P-type well 2 is arranged in the P-type well 2 There are P-type contact hole 6 and N-type source 5, N-type drain 4 is arranged in N-type drift region 3, gate oxide layer 7 is arranged above P-type well 2 and N-type drift region 3, and gate oxide layer 7 is provided with a polysilicon gate 8 and the polysilicon gate 8 is located above the junction of the P-type well 2 and the N-type drift region 3, a field oxide layer 10 is provided above the gate oxide layer 7 and the polysilicon gate 8, and the P-type contact hole 6 An aluminum lead 11 is connected to the N-type source 5, an aluminum lead 12 is connected to the polysilicon gate 8, an aluminum lead 13 is connected to the N-type drain 4, and a polysilicon field plate 9 is arranged in the field oxide layer 10. T...

Embodiment 2

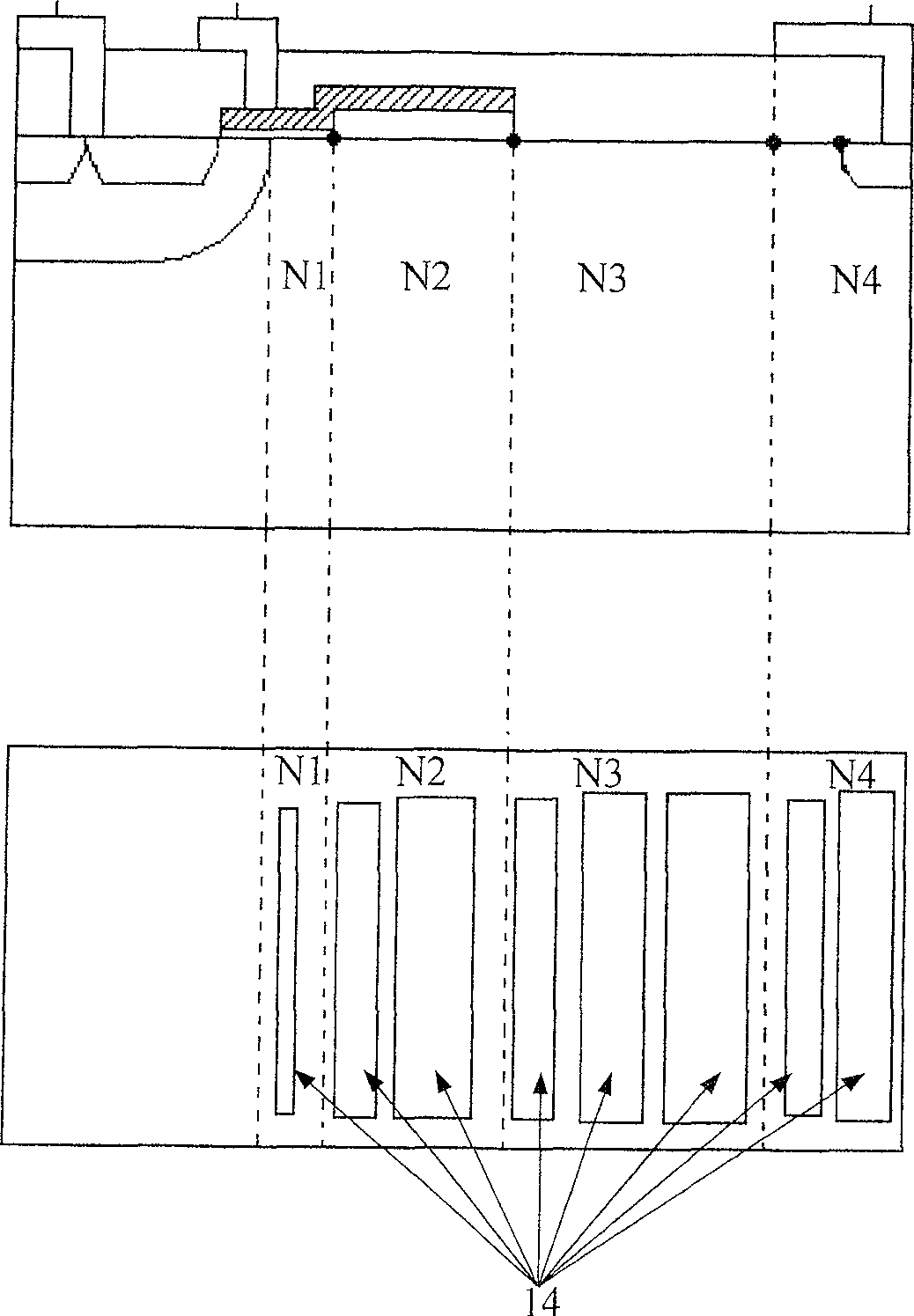

[0017] A preparation method for manufacturing the above-mentioned high-voltage N-type metal oxide semiconductor tube, first prepare an N-type substrate with a concentration of 1×10 15 cm -3 Next, prepare an N-type drift region on the N-type substrate. The drift zone is linearly implanted in four regions, and the implantation windows from small to large are sequentially opened on the photolithography plates of the first to fourth drift regions. After ion implantation, After thermal diffusion, the impurities form a segmented linear distribution in the drift region. After that, the field oxide layer, gate oxide layer, polysilicon gate, P-type well, N-type source, drain and N-type substrate contact holes and contact holes and metal aluminum leads.

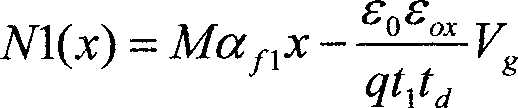

[0018] refer to figure 2 , when the N-type drift region is prepared on the N-type substrate, the drift zone has four linear implants, and each part is doped according to the following equation.

[0019] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com