Method for preparing metal nanometer thin film dipped barium-tungsten cathode

A barium tungsten cathode, metal nanotechnology, applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve problems such as poor processing and brittle tungsten sponge, and achieve the effect of increasing the emission current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

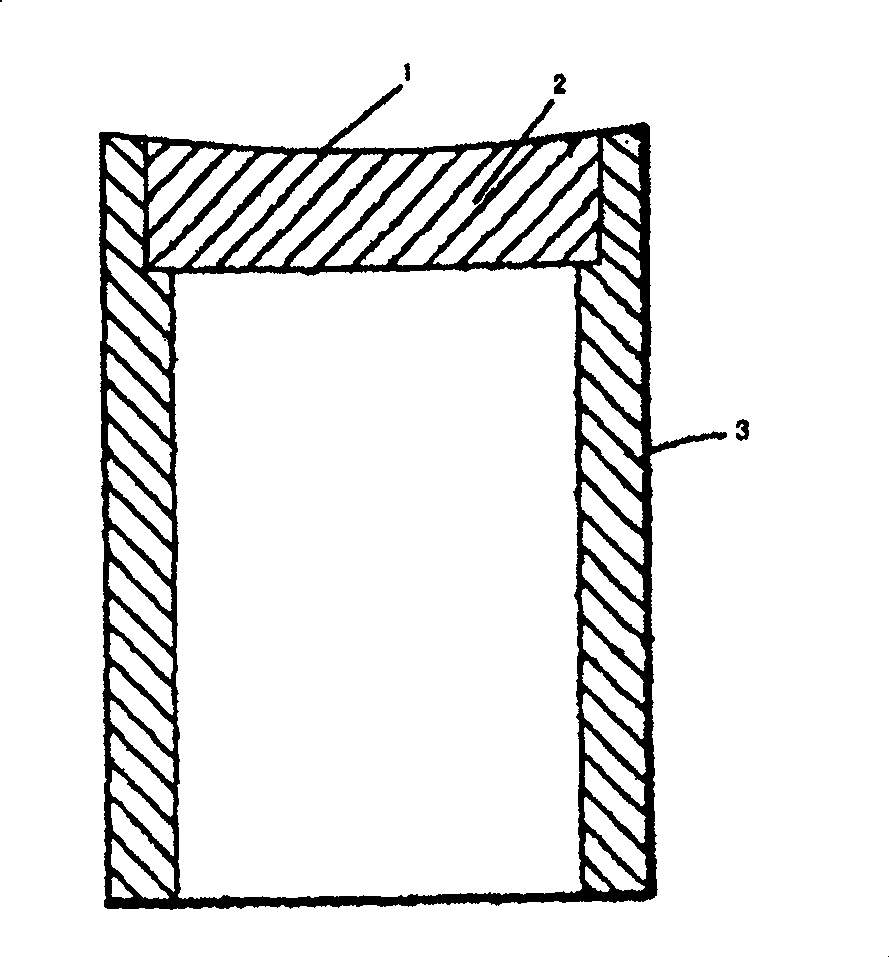

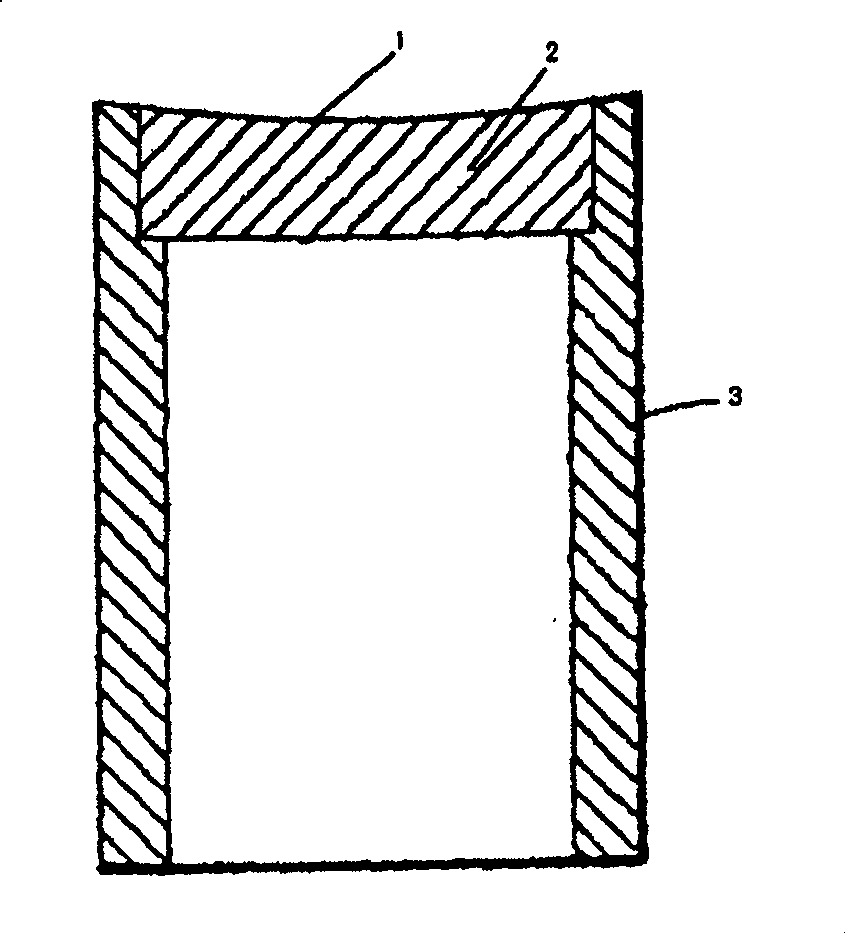

[0015] like figure 2 Shown is a schematic diagram of a novel cathode in which nanoparticles are deposited onto the surface of an impregnated barium tungsten cathode according to the present invention. Put the tungsten sponge base 2 into the cathode support cylinder 3, and weld 2 and 3 firmly by means of electron beam or laser welding. Then the emission material is immersed in the tungsten sponge substrate 2 at high temperature (about 1600°C), and the surface of the cathode is turned into the required arc, and then put into the deposition system of osmium, iridium, rhenium, ruthenium or their alloy nanoparticles, Deposit metal nanoparticles with a particle diameter of 10 nm to 100 nm on the surface of the cathode to form a metal nano particle layer 1 with a thickness of about 0.1 micron to 0.6 micron.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com