Ti/Al2O3 composite material for wave impedance gradient flying plate and manufacture thereof

A composite material and wave impedance technology, which is applied in the field of Ti/Al2O3 composite materials, can solve the problem of in-depth research on flyers with limited wave impedance gradients, low mechanical strength of the transition layer, and difficulty in ensuring the integrity of flyer quasi-isentropic compressibility during supersonic flight To achieve the effect of tight interface, high density and complete structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

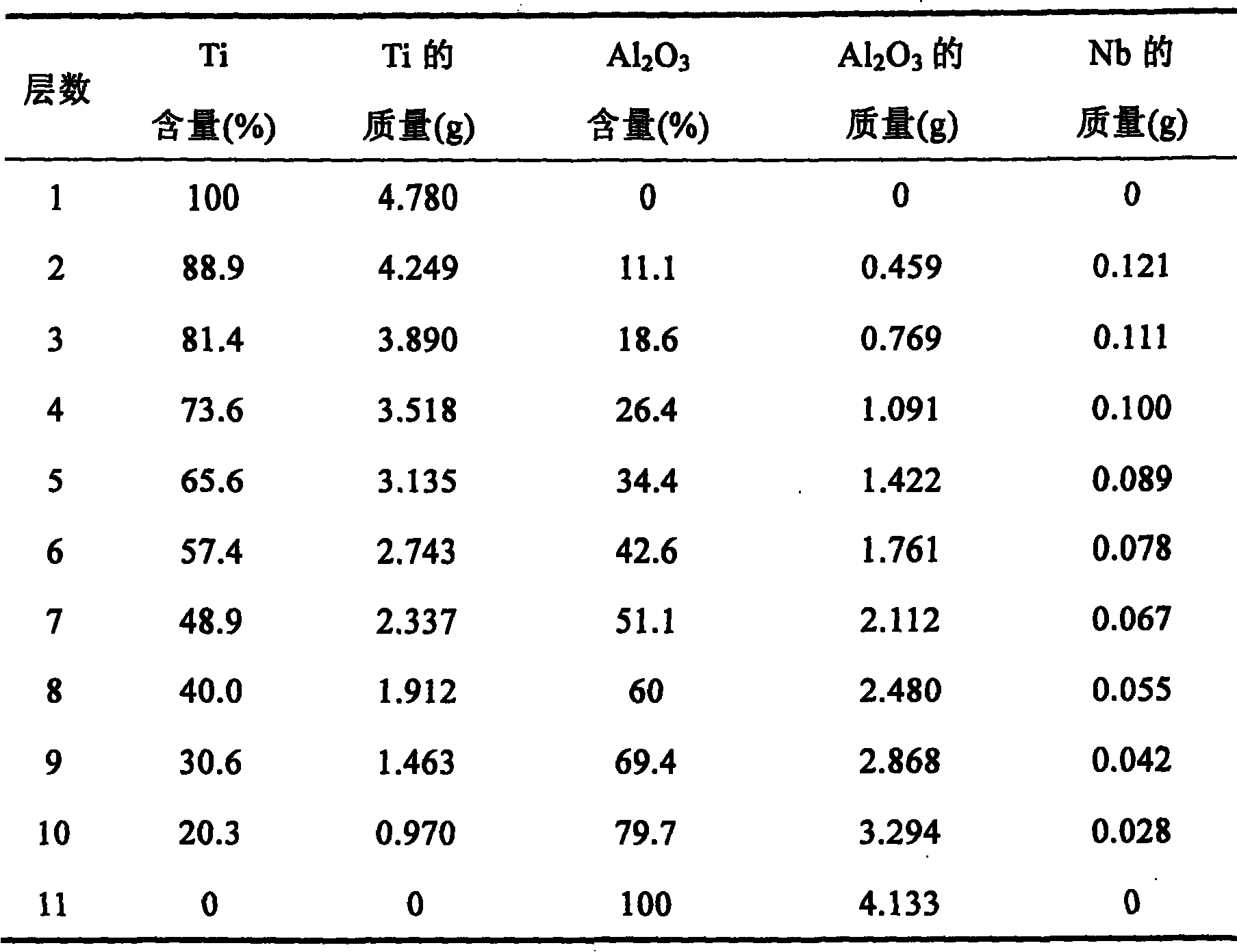

[0023] Ti / Al for wave impedance gradient flyer according to the embodiment of the present invention 2 o 3 The composite material is composed of the following raw materials in weight percentage: Ti is 57.9%, α-Al 2 o 3 40.7% and Nb 1.4%. Table 1 shows the composition distribution of materials when P=0.8 and 11 layers. Ti and Al in the table 2 o 3 The content is volume percentage, with Ti and Al 2 o 3 The total volume of is 100%, and Nb is added according to the Ti content. (the same below)

[0024]

[0025] After the powders of each layer were weighed in proportion, they were mixed separately for 48 hours, and the materials of each layer were pressure-formed, and the thickness of each single-layer bad body was 1.5mm. The formed single-layer blanks were put into graphite molds in the order of decreasing Ti content (high Ti content at the bottom), and then prepared Ti by spark plasma sintering (SPS for short). / Al 2 o 3 For the composite material, the sintering pro...

Embodiment 2

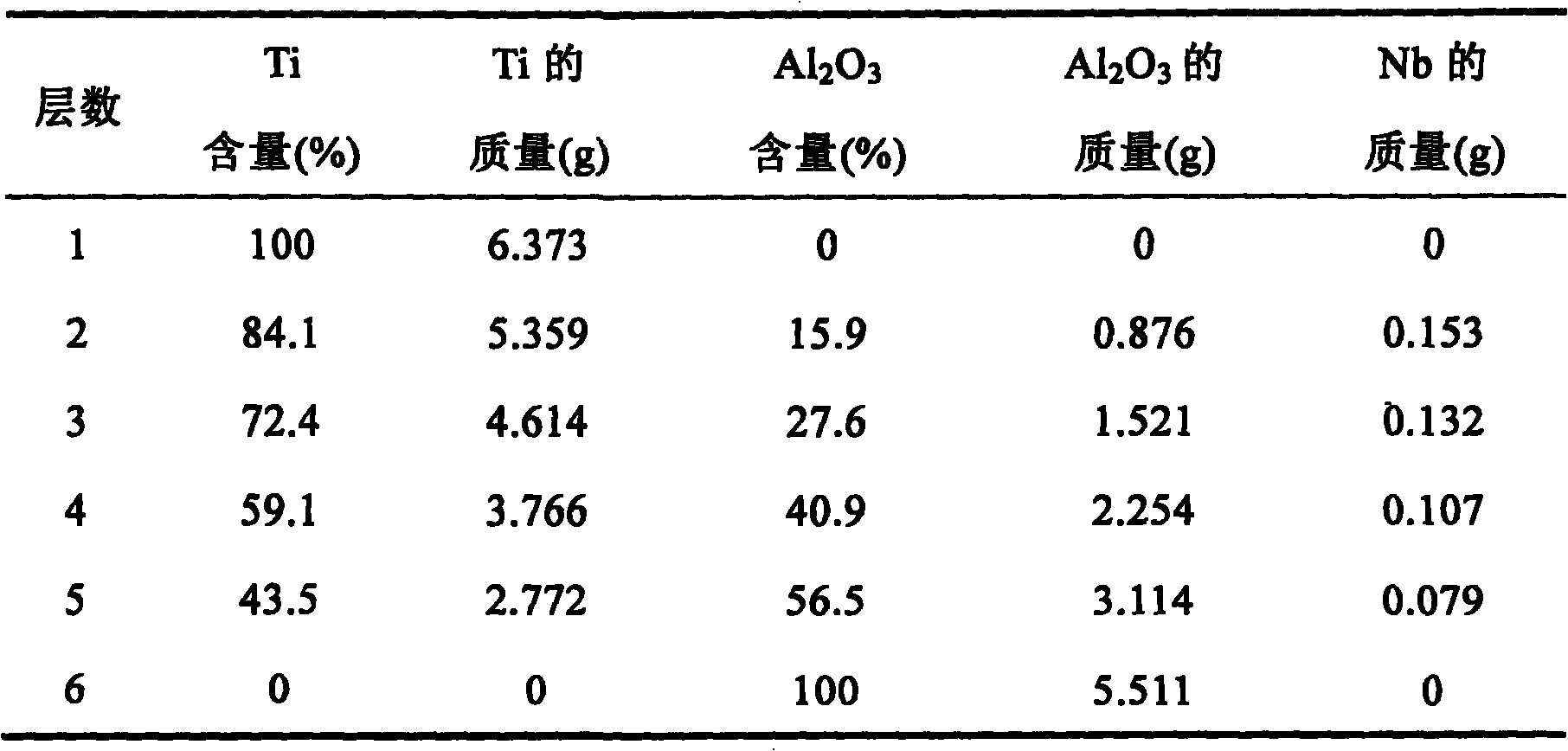

[0028] Ti / Al used for wave impedance gradient flyer of the present invention 2 o 3 The composite material is composed of the following raw materials in weight percentage: Ti is 62.5%, α-Al 2 o 3 36.2% and Nb 1.3%. Table 1 shows the composition distribution of materials when P=0.6 and 6 layers.

[0029]

[0030] After the powders of each layer are weighed in proportion, the materials are mixed separately for 48 hours, and the materials of each layer are formed by pressure, and the thickness of each single-layer bad body is 2mm. The formed single-layer blanks are put into graphite molds in the order of decreasing Ti content (high Ti content is at the bottom), and then prepared by spark plasma sintering (SPS for short). Ti / Al on Flyer with Wave Impedance Gradient 2 o 3 For the composite material, the sintering process is as follows: sintering temperature is 1200°C, holding time is 20min, and heating rate is 150°C / min. The density of the prepared material is 96.8%, the i...

Embodiment 3

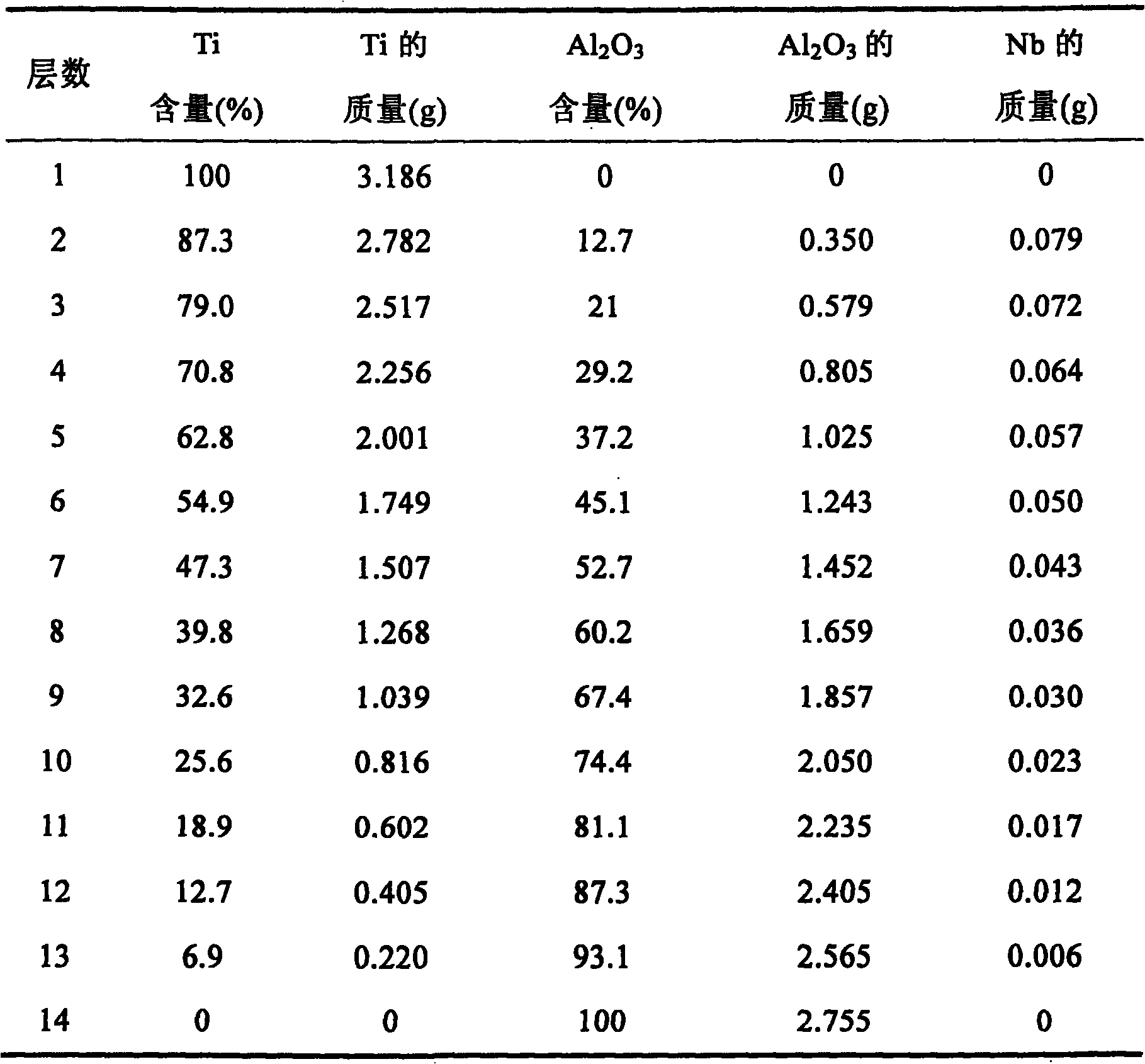

[0032] Ti / Al used for wave impedance gradient flyer of the present invention 2 o 3 The composite material is composed of the following raw materials in weight percentage: Ti is 48.7%, α-Al 2 o 3 50.2% and Nb 1.1%. Table 1 shows the composition distribution of materials when P=1.2 and 14 layers.

[0033]

[0034] After the powders of each layer were weighed in proportion, the materials were mixed separately for 48 hours, and the materials of each layer were pressure-formed, and the thickness of each single-layer bad body was 1mm. The formed single-layer blanks were put into the graphite mold in the order of decreasing Ti content (the one with the highest Ti content at the bottom), and then the Ti was prepared by spark plasma sintering (SPS for short). / Al 2 o 3 For the composite material, the sintering process is as follows: sintering temperature is 1400°C, holding time is 8min, and heating rate is 250°C / min. The density of the prepared material is 97.6%, the interfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com