Water wall paint for external wall

A technology for wall paint and exterior walls, applied in the direction of coating, etc., can solve the problems of poor stain resistance, fading and peeling of wall paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

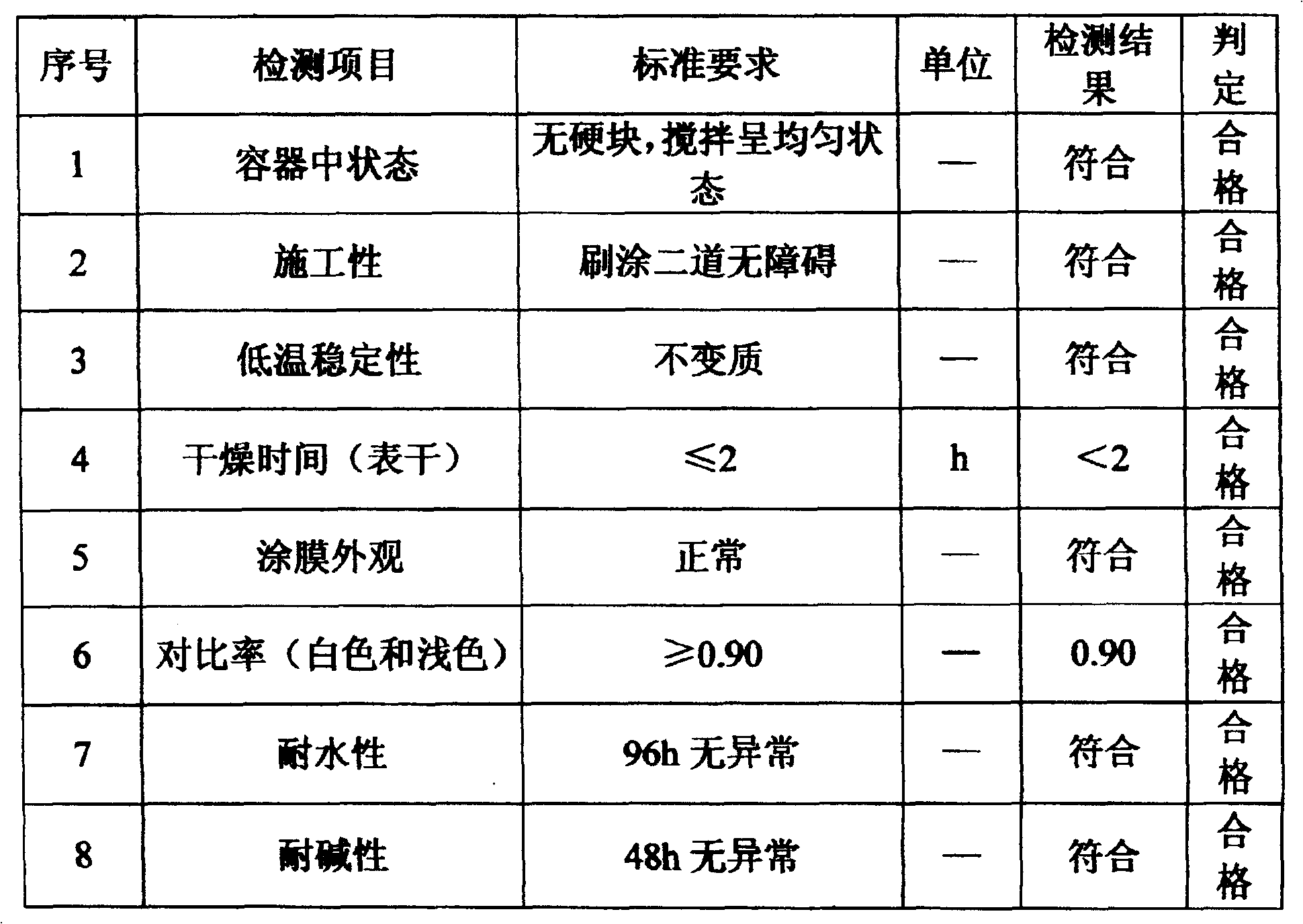

example 1

[0051] The present embodiment is to prepare styrene-acrylic acid ester exterior wall paint, and its formula (unit is kilogram) is as follows:

[0052] Group A

[0053] h 2 O 16.5

[0054] Wetting agent X-405 0.2

[0055] Defoamer NXZ 0.5

[0056] Dispersant 1124 0.5

[0057] 250HBR 0.15

[0058] Preservative LXE 0.1

[0059] Alkali swelling thickener TT-935 0.2

[0060] Ammonia 0.1

[0061] Group B

[0062] Rutile Titanium Dioxide R-595 12.5

[0063] Aluminum silicate 3.75

[0065] Wollastonite 7.5

[0066] Heavy calcium 7.5

[0067] Propylene Glycol 2

[0068] Butyl Carbitol 0.5

[0069] Group C

[0070] Rheological rib agent R2020 0.2

[0071] Styrene Acrylic Emulsion 998A 25

[0072] Opaque Polymer OP-62 4

[0073] Defoamer NXZ 0.2

[0074] Alkali swelling thickener D105 0.5

[0075] h 2 O 8.1

[0076] The specific preparation method is as follows:

[0077] Add the materials of group A under the shear force of low speed 500...

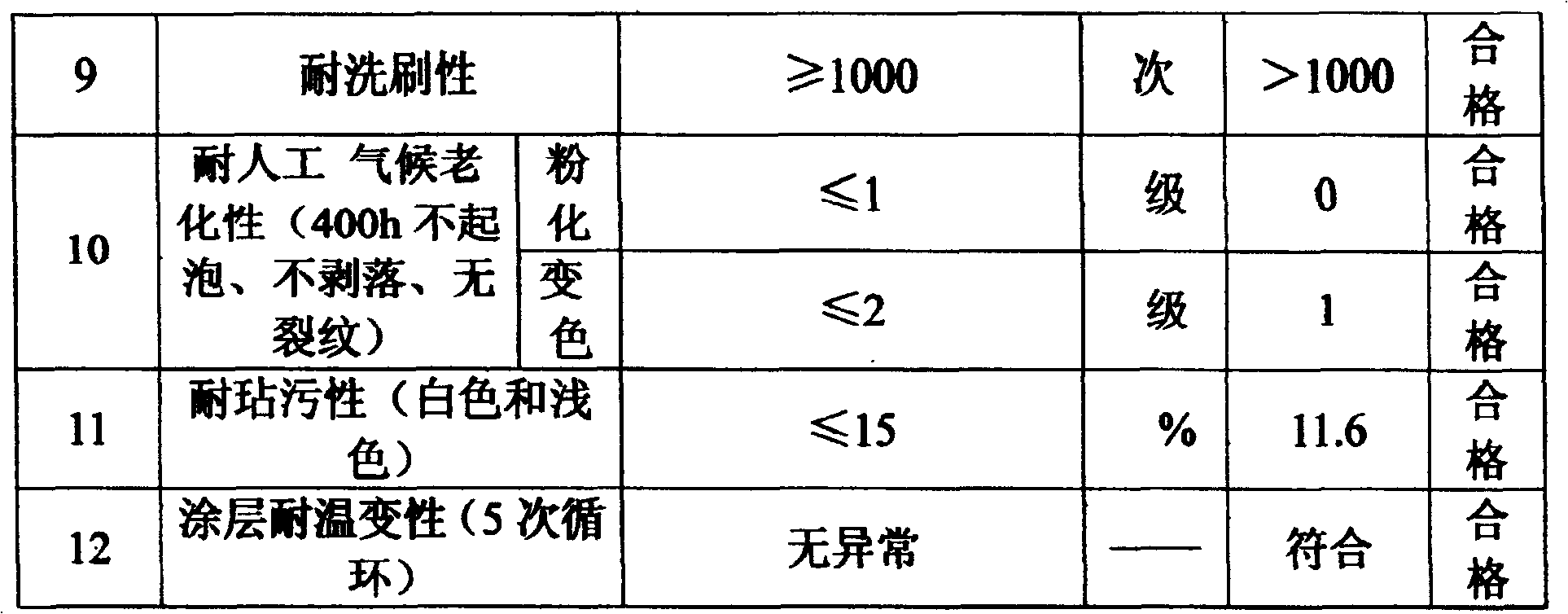

example 2

[0079] Present embodiment is to prepare pure acrylic acid ester exterior wall paint, and its formula (unit is kilogram) is as follows:

[0080] Group A

[0081] h 2 O 15.5

[0082] Defoamer NXZ 0.15

[0083] Wetting agent X-405 0.1

[0084] Preservative LXE 0.2

[0085] Anti-mold and anti-algae agent EPW 0.3

[0086] Dispersant 1124 0.6

[0087] Cellulose 250HBR 0.12

[0088] Alkali swelling thickener TT-935 0.2

[0089] Ammonia NH 3 H2 0 0.15

[0090] Group B

[0091] Rutile titanium dioxide 10

[0092] Aluminum silicate 3.75

[0093] Wollastonite 12.5

[0095] Coalescent 1

[0096] Propylene Glycol 2.5

[0097] Ethylene glycol monobutyl ether 0.8

[0098] Rheology additive 0.2

[0099] Group C

[0100] Pure acrylic emulsion AC-261 31

[0101] Opaque Polymer OP-62 4

[0102] Non-silicone defoamer NXZ 0.15

[0103] Alkali swelling thickener TT-935 0.3

[0104] h 2 O 1.48

[0105] The specific preparation method is as ...

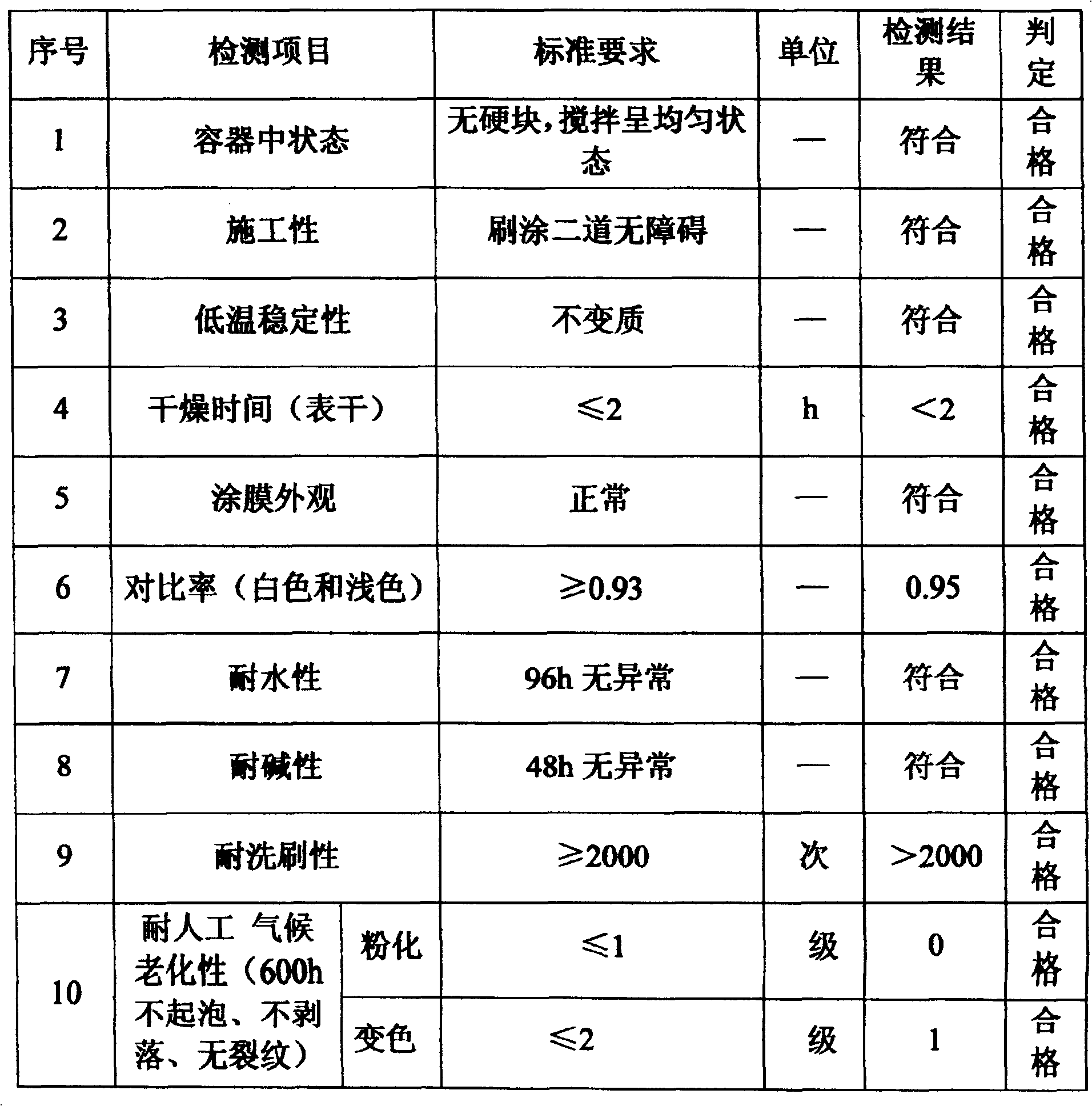

example 3

[0108] The present embodiment is to prepare organosilicon-modified acrylate exterior wall paint, and its raw material formula (unit is kilogram) is as follows:

[0109] Group A

[0110] h 2 O 17.8

[0111] Wetting agent X-40 50.2

[0112] Defoamer NXZ 0.2

[0113] Preservative LXE 0.15

[0114] Hydroxyethylcellulose 250HBR 0.1

[0115] Alkali swelling thickener TT-935 0.1

[0116] Propylene glycol 2.2

[0117] Ammonia NH 3 H2 0 0.1

[0118] Group B

[0119] Rutile titanium dioxide R-595 18

[0120] Ultrafine Barium Sulfate 10

[0121] Ground calcium carbonate 5

[0122] Ethylene glycol monobutyl ether 0.5

[0123]Butyl Carbitol 0.5

[0124] Coalescent 1.5

[0125] Group C

[0126] Silicone modified acrylate 36

[0127] K201

[0128] Opaque Polymer OP-62 5

[0129] Defoamer NXZ 0.1

[0130] Polyurethane thickening rheology additive 0.4

[0131] Alkali swelling thickener TT-935 0.2

[0132] Anti-mold and anti-algae agent EPW 0.4

[0133] h 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com